Automotive rotating motor

A technology for rotating electrical machines and vehicles, applied to the shape/style/structure of the winding insulation, the shape/style/structure of the winding conductor, etc., can solve the problems of cost increase, achieve the effect of improving the cooling effect and improving the maximum performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

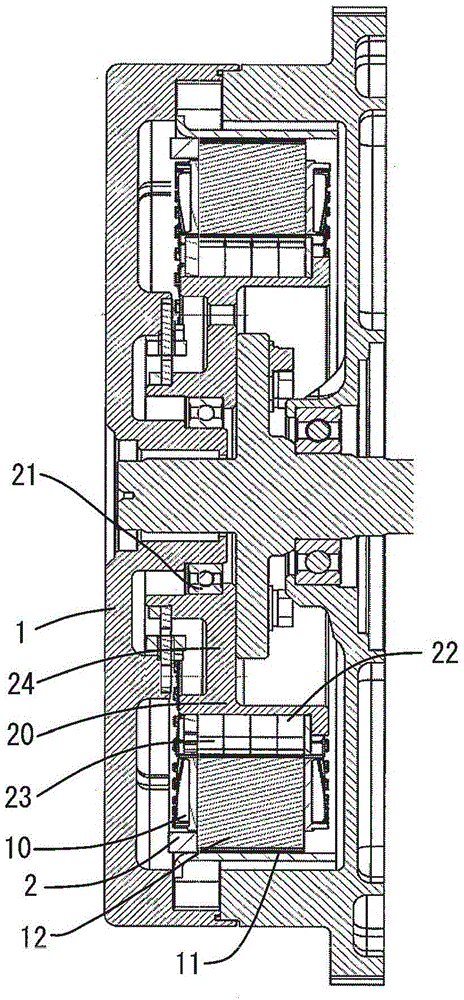

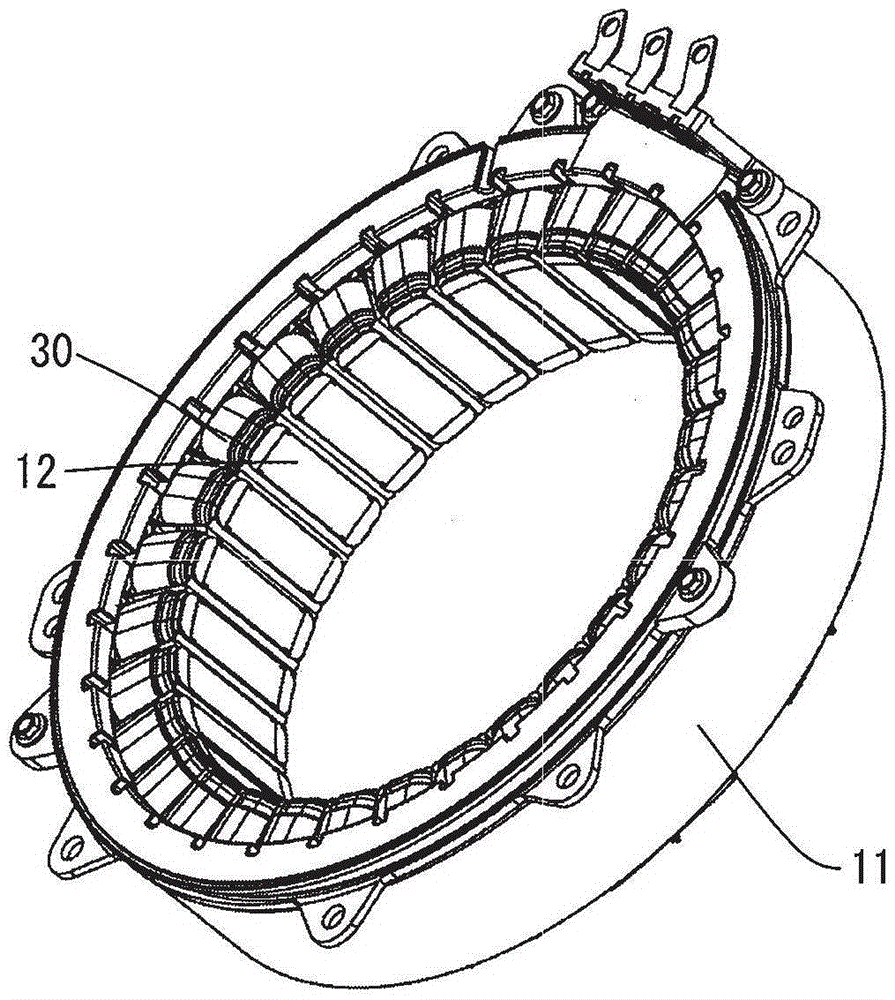

[0025] figure 1 It is a sectional view showing the structure of the rotating electrical machine in Embodiment 1 of the present invention. Such as figure 1 As shown, the rotating electric machine in Embodiment 1 includes a stator 10 and a rotor 20 . A rotor core 22 made of laminated steel plates is arranged on the outer peripheral side of the rotor 20 , and a permanent magnet 23 is arranged inside it. The rotor core 22 is fixed such that its inner peripheral portion is press-fitted into the outer peripheral portion of a rotor boss portion 24 .

[0026] On the other hand, the stator 10 is configured by press-fitting an iron core 12 made of the same laminated steel plates into the inner periphery of an annular frame 11 . A predetermined gap is provided between the inner circumference of the core 12 and the outer circumference of the opposing rotor core 22 .

[0027] The rotor 20 is held rotatably relative to the housing 1 by a bearing 21 disposed on the inner periphery of the...

Embodiment approach 2

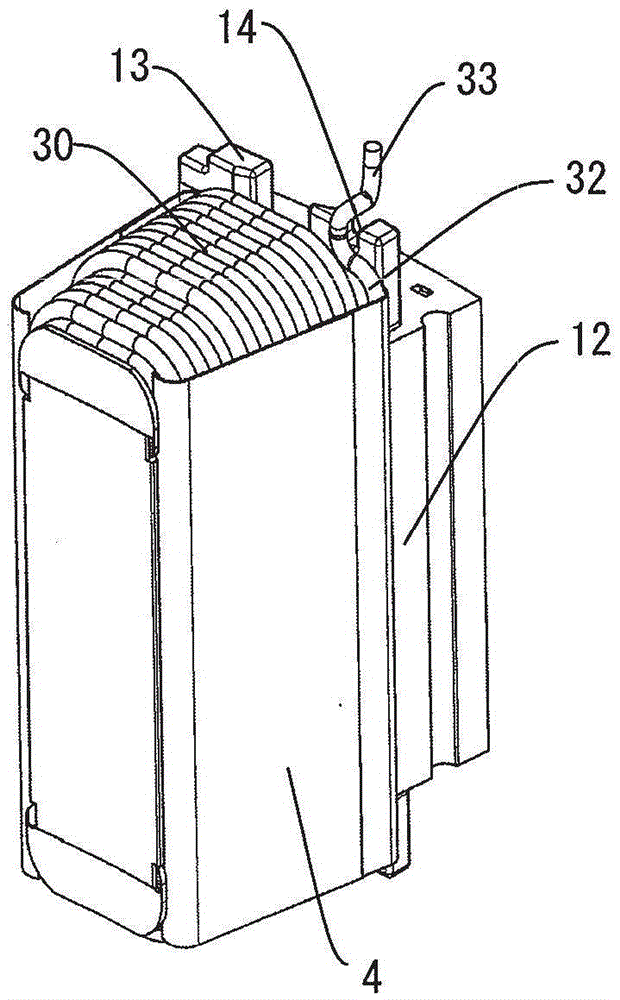

[0037] In this Embodiment 2, the method of improving the cooling effect by improving the arrangement|positioning of the last turn part 32 of a coil is demonstrated.

[0038] Figure 5 It is a perspective view showing a detailed configuration of a winding portion of a stator of a rotating electrical machine according to Embodiment 2 of the present invention. Figure 5 In , the state without the outermost insulating paper 4 is shown. Image 6 It is a cross-sectional view of a winding portion of a stator of a rotating electrical machine according to Embodiment 2 of the present invention.

[0039] In Embodiment 2, in the step of forming the final turn portion 32 of the coil, as Figure 5 As shown, the linear portion 34 is arranged so that it moves toward the center portion of the groove. Thus, if Image 6 As shown, the corner portion on the outer peripheral side of the insulating paper 4 is made to protrude toward the opposite coil side from the extension line of the core divi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com