Peeling machine

A technology of rotary cutting machine and rotating cylinder, which is applied in the direction of turning equipment, metal processing equipment, turning equipment, etc., which can solve the problems of labor and time, deformation, and wear of the push bearing surface, so as to achieve smooth and stable sliding and durable lifting Sexuality, the effect of safe work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Hereinafter, the present invention will be described in detail based on the illustrated embodiment.

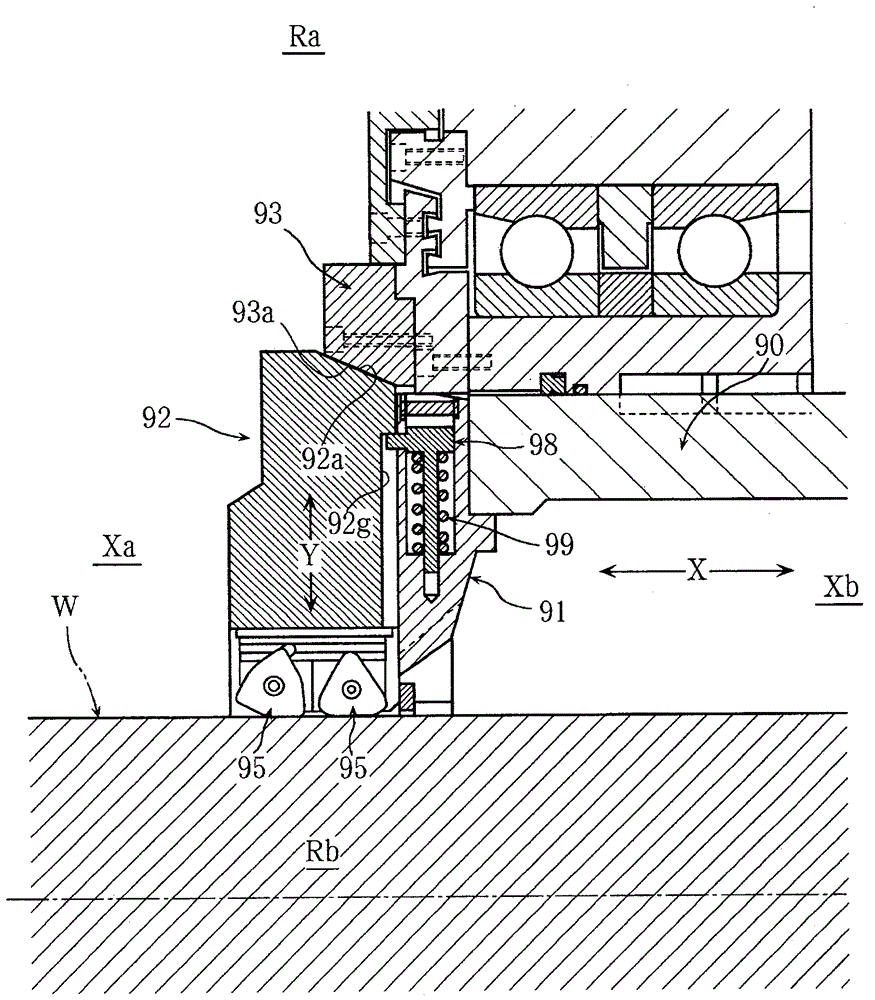

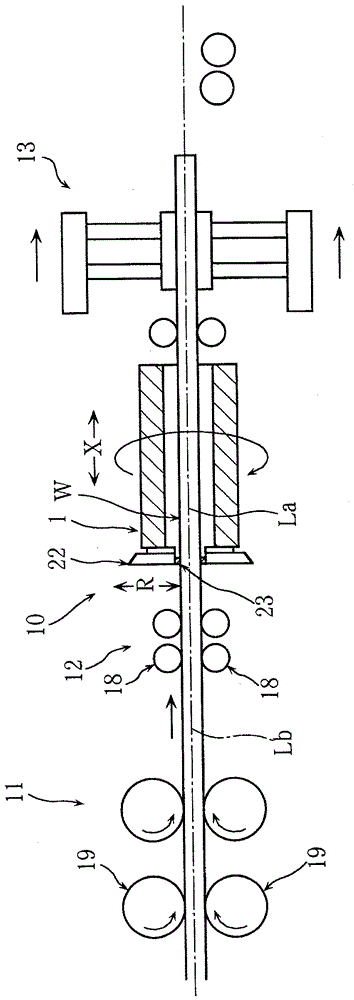

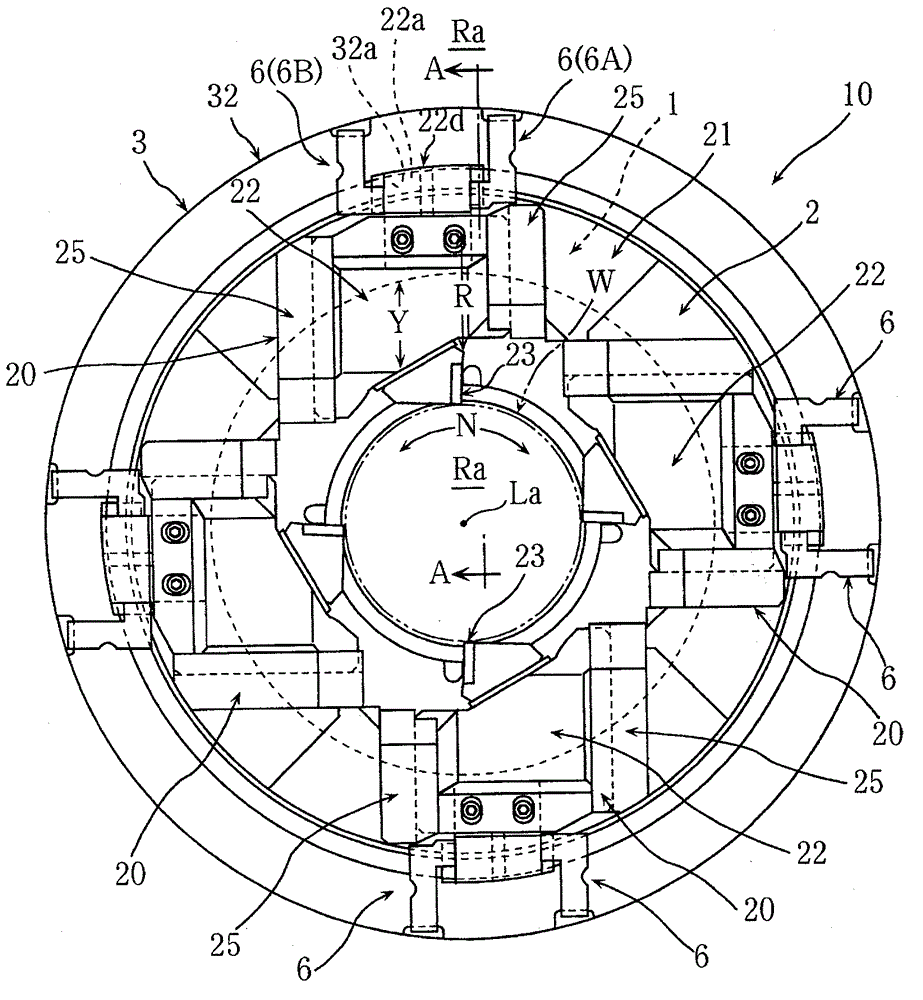

[0022] Such as figure 1 As shown, the rotary cutting machine related to the present invention includes a cutting device 10, a feeding device 11, a guide device 12, and a stage device 13. The cutting device 10 includes a rotating drum 1 and a tool holder 22. The rotating drum 1 is metal The round rod-shaped workpiece W is inserted through and rotates around the rotation axis La under the action of the motor. The aforementioned tool holder 22 is mounted on the rotating drum 1, and rotates around the rotation axis La, and is mounted on the outer peripheral surface of the cutting workpiece W. Blade 23, the aforementioned feeding device 11 is equipped with two sets of feeding rollers 19, 19, the aforementioned feeding rollers 19, 19 are a pair of upper and lower feeding rollers that feed the workpiece W into the rotating drum 1, and the aforementioned guiding device 12 has mult...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com