Retardation film, polarizing plate using same, and display device

A technology of retardation film and retardation enhancer, applied in polarizing elements, applications, household appliances, etc., can solve the problems of uneven color and variation of liquid crystal display devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

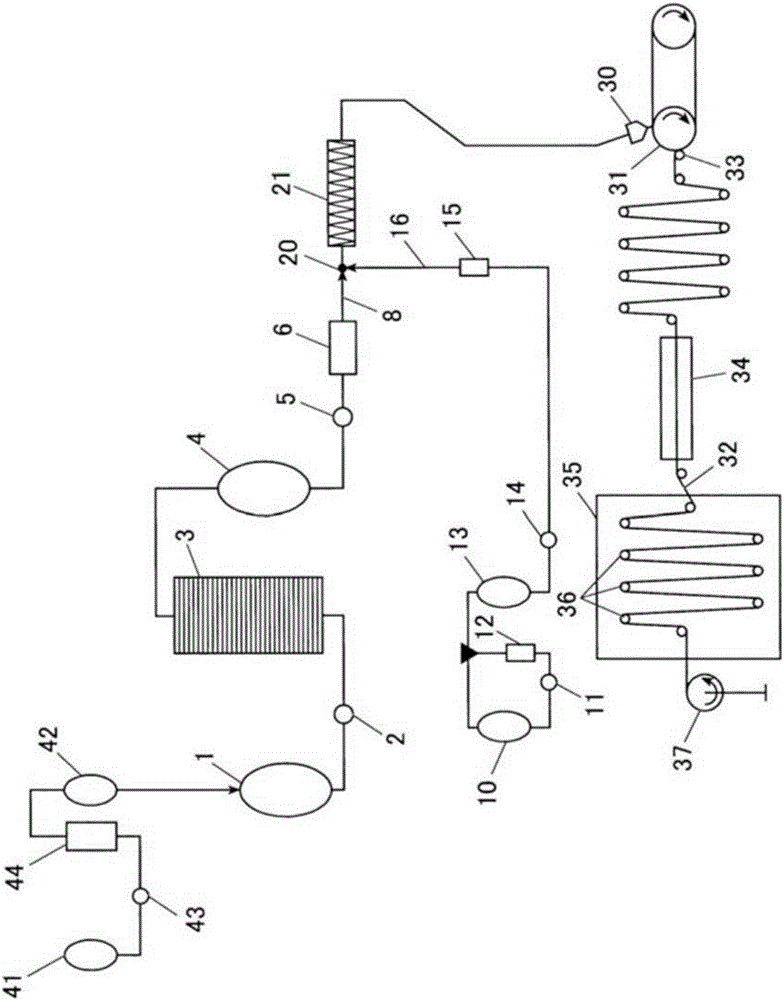

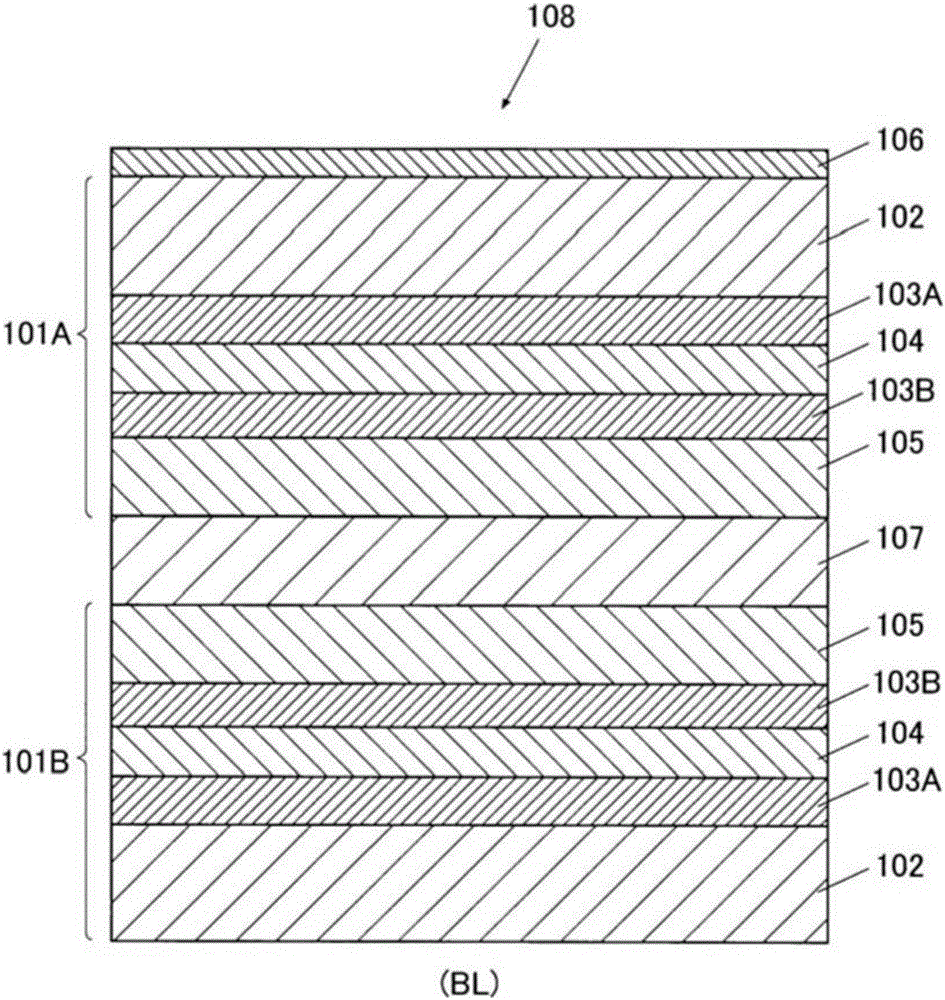

Method used

Image

Examples

Synthetic example

[0207] (Synthesis example: Synthesis example of sugar ester compound)

[0208] [chemical formula 22]

[0209]

[0210] 34.2g (0.1 mol) of sucrose, 135.6g (0.6 mol) of benzoic anhydride, and 284.8g (3.6 mol) of pyridine are charged in a four-necked flask with a stirring device, a reflux cooler, a thermometer and a nitrogen inlet pipe, while stirring While boiling nitrogen gas from a nitrogen gas introduction tube, the temperature was raised, and esterification reaction was performed at 70° C. for 5 hours.

[0211] Next, reduce the pressure in the flask to 4×10 2 Pa or below, after distilling off excess pyridine at 60° C., the inside of the flask was depressurized to 1.3×10 Pa or below, the temperature was raised to 120° C., and most of benzoic anhydride and generated benzoic acid were distilled off. Then, 1 L of toluene and 300 g of a 0.5 mass % sodium carbonate aqueous solution were added, and after stirring at 50° C. for 30 minutes, the mixture was left still, and the to...

Embodiment

[0504] Hereinafter, although an Example is given and this invention is demonstrated concretely, this invention is not limited to these. In addition, in an Example, the expression of "part" or "%" is used, and unless otherwise specified, it means "part by mass" or "% by mass".

[0505] "Retardation film production"

[0506] [Production of Retardation Film 101]

[0507]

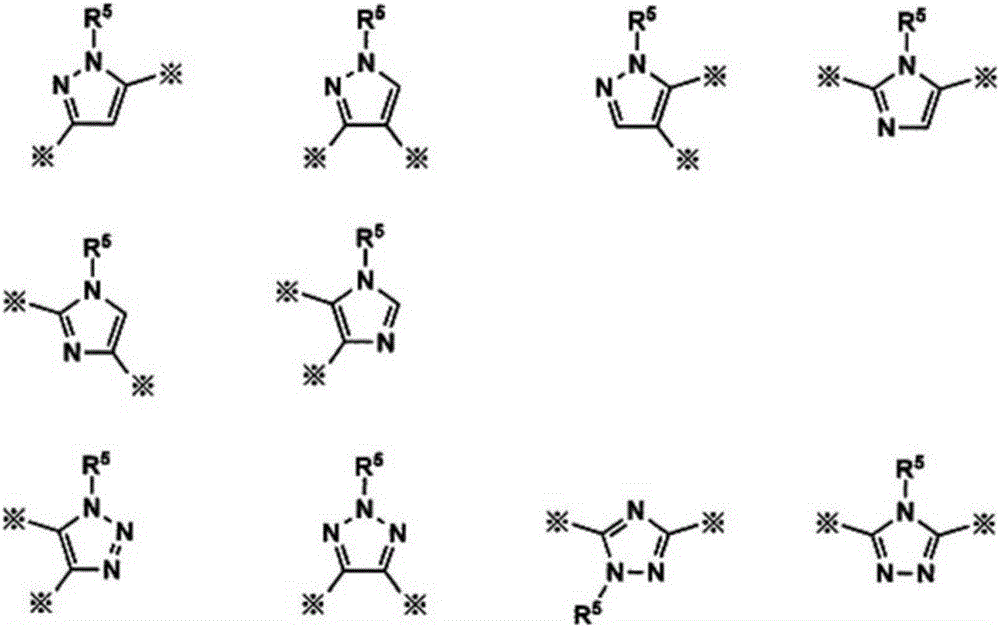

[0508] A retardation enhancer obtained by mixing Compound 38 (nitrogen-containing compound (A)) and Compound 150 (nitrogen-containing compound (B)) at a mass ratio of 99.9:0.1 was used.

[0509]

[0510] While heating, the following components were sufficiently stirred and dissolved to prepare a main dope liquid.

[0511] Cellulosic resin C1 (diacetyl cellulose having an acetyl substitution degree of 2.41 and a weight average molecular weight (Mw) of 56,000): 100 parts by mass

[0512] Phase difference enhancer (nitrogen-containing compound (A)+nitrogen-containing compound (B)): 3 parts by mass

[0513]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com