A flatting and puddling paddy field machine through shaft type cutter shaft roller with cage-type cutter rests and toothed cutters

A pulper and through-shaft technology, which is applied in the field of the through-shaft cage-type knife holder toothed cutter shaft roller field of the paddy field flat ground pulper, which can solve the insufficient rigidity of the cutter shaft roller of the large model and the grass wrapping operation of the cutter shaft roller Efficiency, the blade is easy to loose and other problems, to achieve the effect of not easy to loose, low maintenance cost, high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

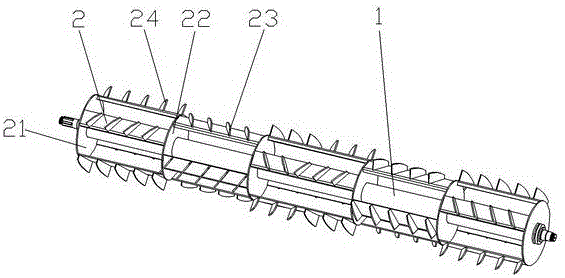

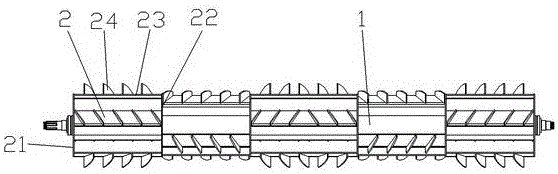

[0012] see figure 1 As shown, the present invention is composed of a cutter shaft tube 1 and an array of tool rest mechanisms 2, and the array of tool rest mechanisms 2 are fixedly arranged on the cutter shaft tube 1 respectively. It is a "squirrel cage" structure;

[0013] The tool rest mechanism 2 includes a first cutter disc 21, a second cutter disc 22, a tool rest beam 23 and several toothed blades 24, and the first cutter disc 21 and the second cutter disc 22 are respectively fixedly arranged on the cutter shaft tube 1, Two ends of several knife rest beams 23 are fixedly arranged on the first cutter head 21 and the second cutter head 22 respectively, and several toothed blades 24 are fixedly arranged on the knife rest beam 23 respectively, and several toothed blades 24 are fixed on the knife rest. Beams 23 are equidistantly arranged.

[0014] Working principle and process of the present invention:

[0015] see figure 1 As shown, when working, when the power is transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com