Working principle of vacuum filtration salt leaching machine on saline-alkali land and application of vacuum filtration salt leaching machine

A technology of saline-alkali soil and salt washing machine, which is applied in the fields of application, agricultural machinery and implements, and soil-lifting machinery, etc., can solve the problems of heavy workload, high cost, and harm to plant growth, etc., and achieves high operating efficiency, high cost, and repeated long-term effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

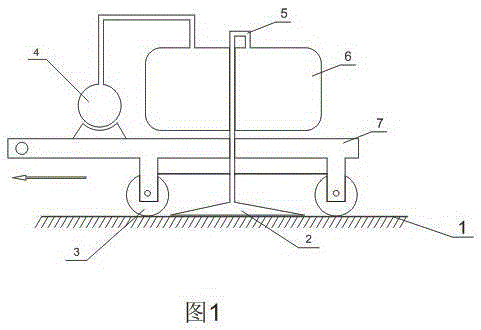

[0026] The power output of the power machine is used to drive the vacuum machine, and the negative pressure generated at the same time is transmitted to the vacuum suction cup, and acts on the sprayed or irrigated ground through the filter crawler. The huge negative pressure generated by the vacuum machine removes the saline-alkali solution from the soil layer. The extraction is separated out and collected into the collection tank. Under the constant speed traction of the tractor (or other power machinery), the fuselage is driven and the filter crawler is driven, so as to continuously extract the saline-alkali solution in the soil during the displacement process to achieve the purpose of removing the saline-alkali components in the soil.

[0027] Before operation, it must be fully sprayed or watered with water on the saline-alkali ground. Generally, the depth of water penetration is 20cm-30cm, and the humidity is 30%-40%. Soluble salts such as sodium sulfate, sodium carbonate,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com