A continuous production line device for shortbread

A production line and bread technology, applied in the direction of dough processing, dough forming and cutting combination, dough forming and cutting equipment, etc., can solve the problems of low production efficiency of crispy bread, inconvenient disassembly, machine cleaning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

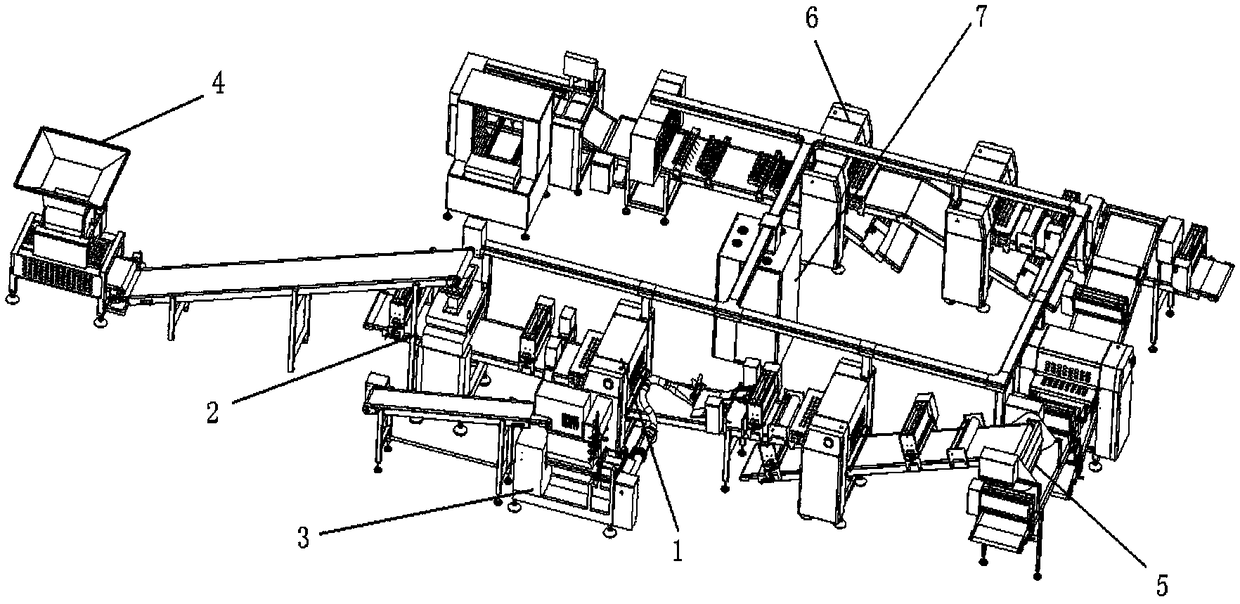

[0063] Embodiment 1 discloses a kind of crisp bread continuous production line device, as figure 1As shown, it includes a central processing unit 7, a four-corner shearing machine 4, a hexagonal shaping machine 2, a multi-roll noodle rolling machine 1, an oil dispenser device 3, a noodle stacking machine 5 and a split table cutting machine 6. During production, the whole piece The unformed dough is first put into the four-corner shearing machine 4 to cut into small pieces of dough of a certain size, and then the small pieces of dough are transported to the hexagonal shaping machine 2 for processing to form dough strips, and then the processed dough strips are transported to The multi-roller noodle rolling machine 1 carries out rolling and pressing to fix the width and thickness of the noodle strips. The oiler device 3 is used to stir the solid oil evenly and transport it to the outside. The viscous oil output from the oiler device 3 is sprayed on the On the surface of the fixe...

Embodiment 2

[0071] It is exactly the same as the connecting device in embodiment 1, the difference is that in embodiment 2, the continuous production line device for crisp bread is provided with multiple multi-roller rolling machines, and two sets of Multi-roller noodle rolling machine, also be provided with three multi-roller noodle rolling machines between oiler device and stacking machine device, also be provided with two multi-roller noodle rolling machines directly with stacking machine and split table cutting machine. The cut noodle strips enter the packaging machine for packaging.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com