A flushing system and flushing method for a filter tank body

A flushing system and filter technology, which is applied in separation methods, filtration separation, chemical instruments and methods, etc., can solve the problems of dirty tank flushing, stirring frame failure, ceramic plate wear, etc., to achieve good flushing effect and complete cleaning , running smoothly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

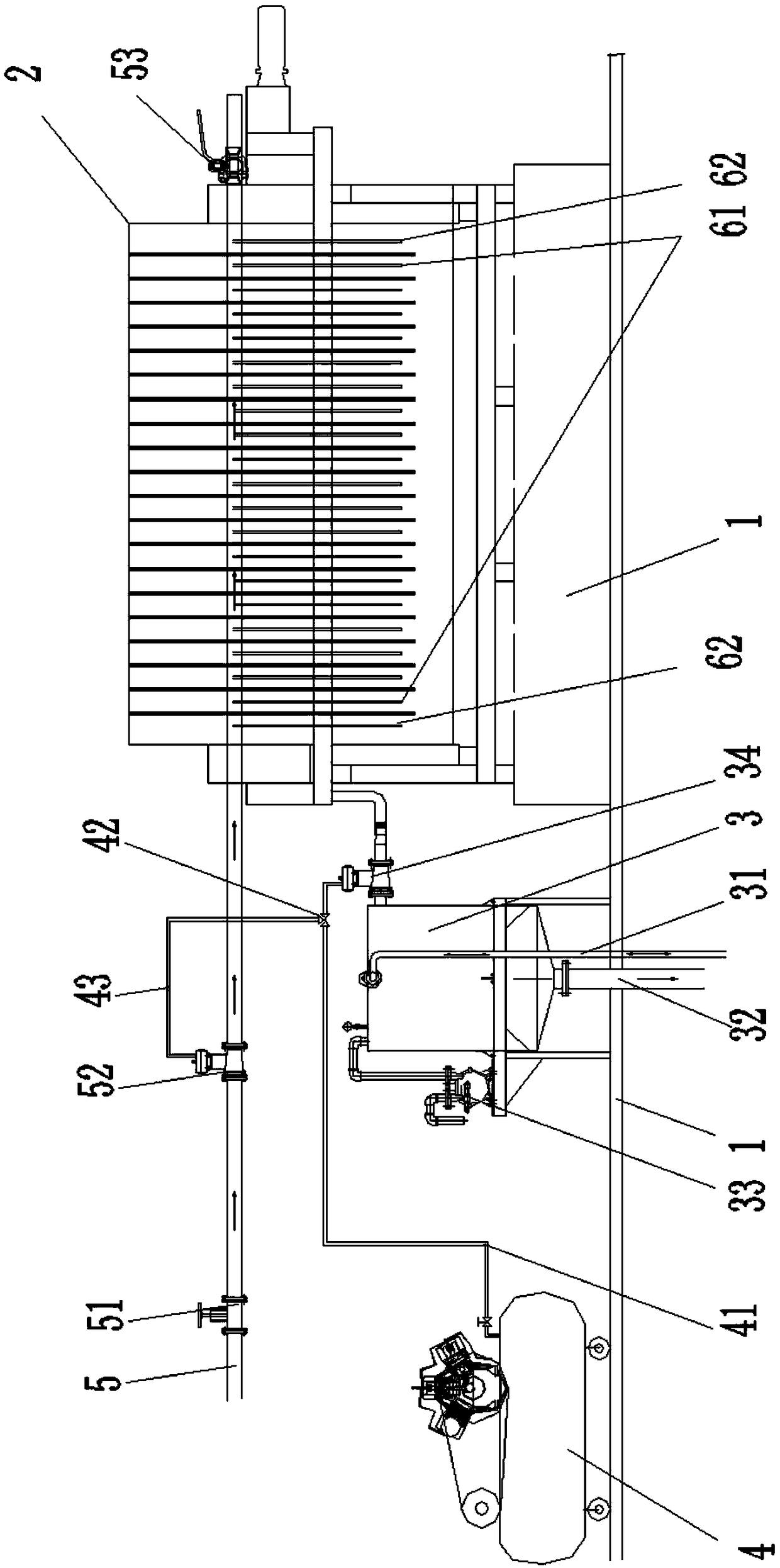

Embodiment 1

[0044] In the prior art, the equipment has many deficiencies: one is that the flushing water on the left side and the flushing water on the right side are the same main pipe, and the two diversions cause obvious insufficient pressure, and the water pressure is not enough to clean the tank body; The existing flushing system installed on the right side of the unloading area can only flush several rows of ceramic plates, but the position between the rows of ceramic plates cannot be flushed; the third is the thin aluminum-plastic pipe installed in the original unloading area And it is short and cannot go deep into the tank body, resulting in poor effect; there is no flushing water installed at the crank arms of the four pairs of stirring brackets, causing the stirring screws to often fall off in actual production, resulting in a high frequency of major production accidents. The cleaning system of the existing ceramic filter is not perfect, the flushing effect is not good, and the c...

Embodiment 2

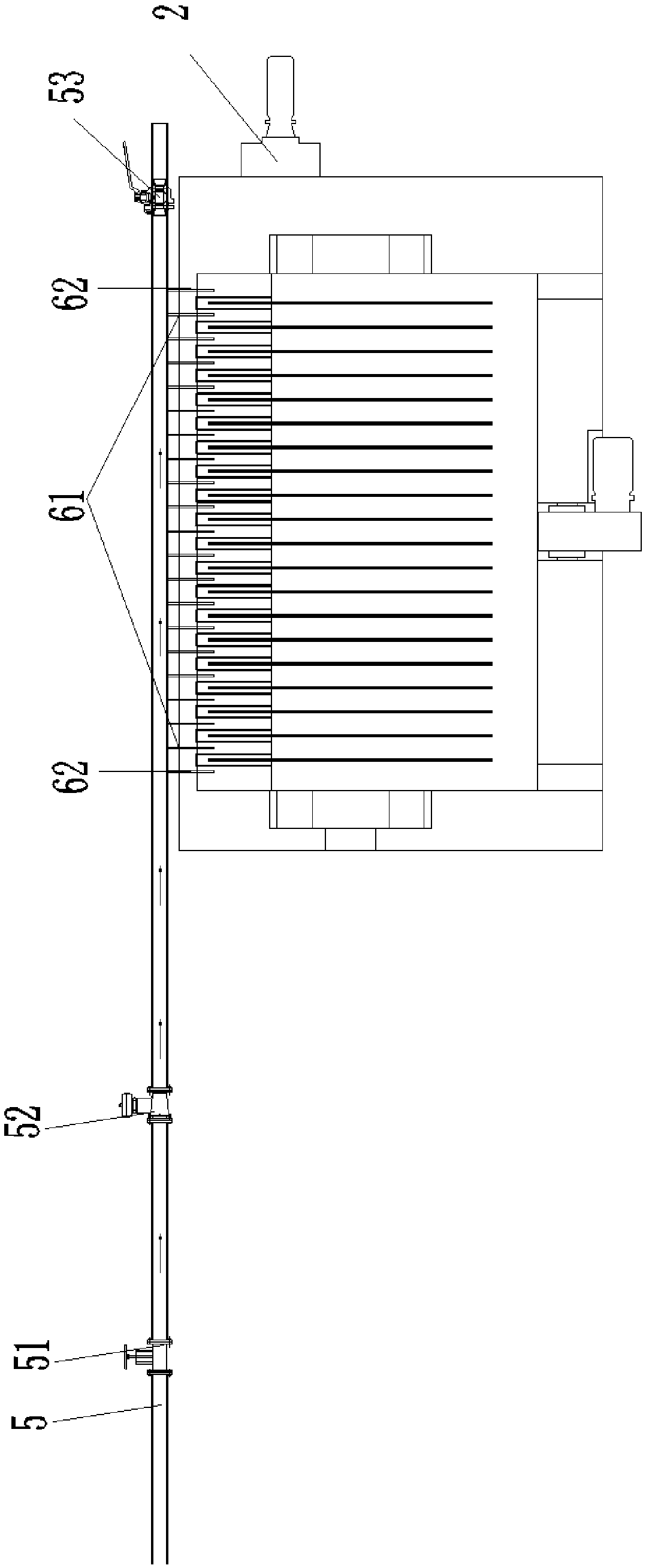

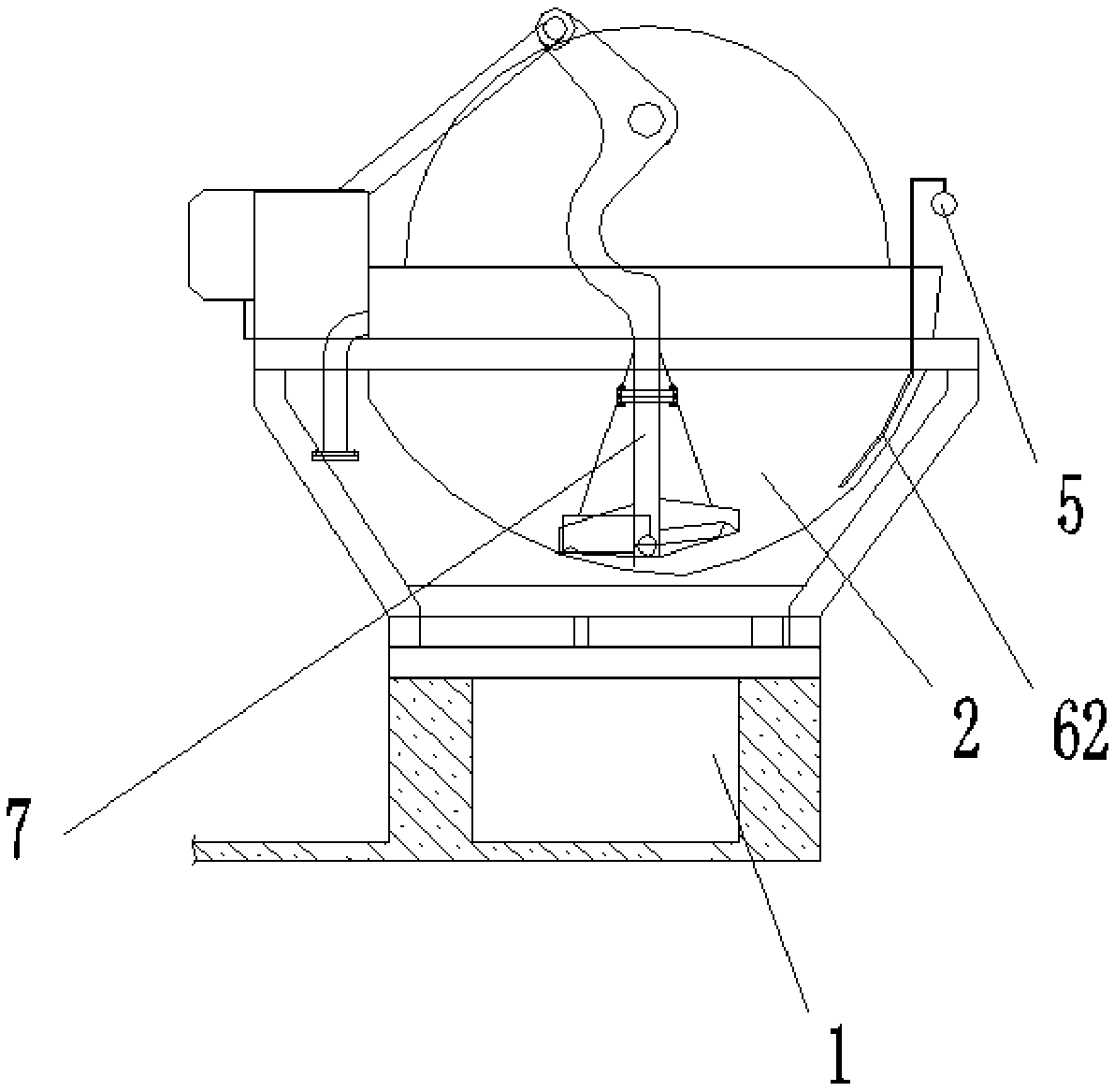

[0051] Embodiment 2 is basically the same as Embodiment 1, the difference is that, as Figure 4 As shown, the flushing water pipe I61 and the flushing water pipe II62 extend into the ceramic filter 2, and both the flushing water pipe I61 and the flushing water pipe II62 include a flushing inlet 63 and then pass through a flushing flat pipe 65, a flushing vertical pipe 66, and a flushing elbow 67 to reach a flushing outlet 64 , the flushing elbow 67 in the lower part is a bent concave shape, and the curvature is compared with different types of filter tanks on site, and the size is determined and uniformly manufactured, so as to fully ensure that it fits the tank and does not affect the operation of the stirring frame 7 , the flushing outlet 64 at the end of the flushing water pipe I61 and the flushing water pipe II62 is a flat oval water outlet, and the ends are made flat and small to increase the momentum and facilitate flushing. Installing at 7 places on the left and right st...

Embodiment 3

[0053] Embodiment 3 is basically the same as Embodiment 1, the difference is that an inlet gate valve 51 is also provided on the water inlet pipeline 5 for independent control, and a blowdown valve 53 is arranged at the tail of the water inlet pipeline 5, and when the water inlet pipeline 5 is blocked, Carry out drainage. Both ends can be controlled independently, which is convenient for the staff to maintain and open the pipeline.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com