A tool and method for controlling the wall thickness uniformity of hot isostatic powder metallurgy thin-walled components

A technology of thin-walled components and control methods, applied in other manufacturing equipment/tools, engine components, turbines, etc., can solve the problems of poor wall thickness uniformity and difficult wall thickness control, and achieve good assembly accuracy, ensure assembly accuracy, and improve The effect of guiding and assembly positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

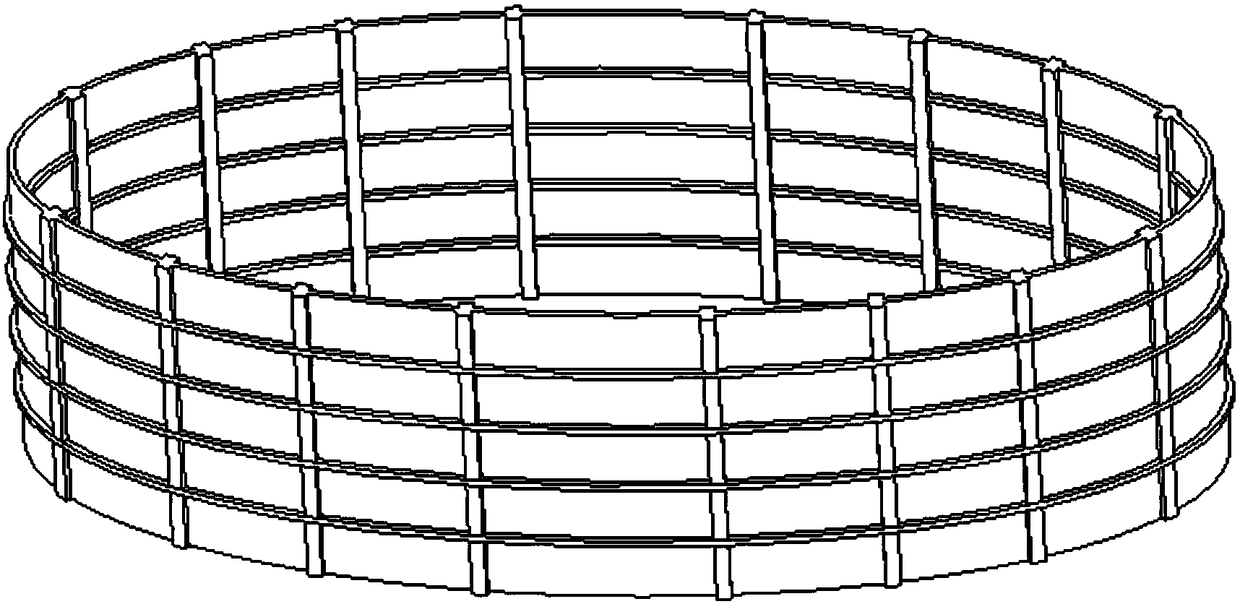

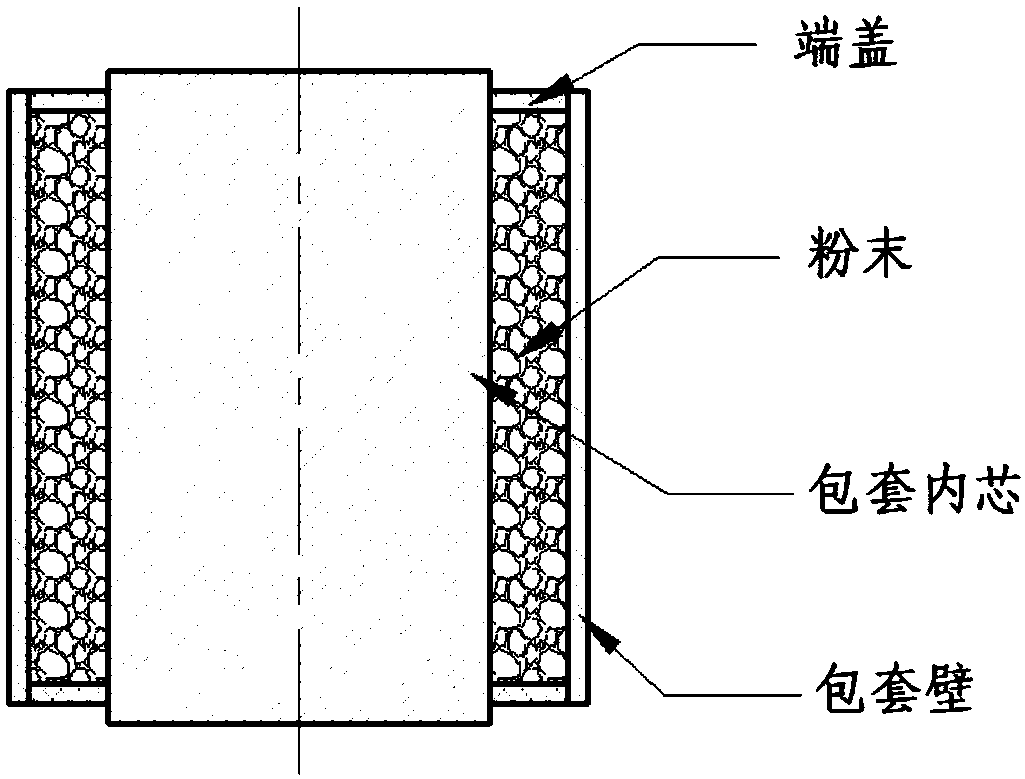

[0052] A wall thickness uniformity control tool for hot isostatic powder metallurgy thin-walled components. Insert 6 and outer support 7, such as Figure 4 and Figure 5 shown;

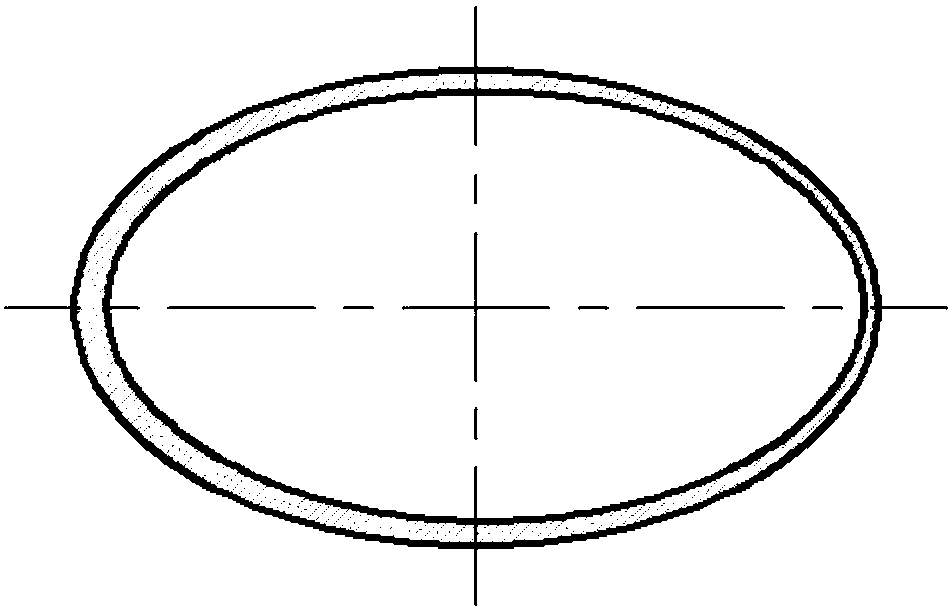

[0053] The inner core 1 of the envelope is cylindrical, and its cross-section is elliptical, the major axis of the ellipse is 800mm, the minor axis is 200mm, and the height is 400mm;

[0054] The gap between the inner core 1 and the wall 2 is used to fill the powder to be formed, and the distance between the inner core 1 and the wall 2 is not less than the wall thickness of the thin-walled member to be formed;

[0055] The upper limit insert 5 is an annular structure, and the cross-sectional view is as follows Figure 6 shown. The inner surface of the upper limit insert 5 is matched with the outer surface of the inner core 1 of the sheath, and the fit gap is 0-0.05mm; the outer surface of the upper limit insert 5 is in contact with the inner surface of the sheath wall 2, and the fit clearance is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com