Grouting material for reinforcing medium-coarse sand layer and preparation method thereof

A technology for grouting materials and coarse sand layers, which is applied in the field of grouting materials for medium and coarse sand layer reinforcement and its preparation, which can solve the problems of low strength, long hardening time, and poor reactivity of building materials, and improve performance uniformity , easy to operate, and prolong the shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

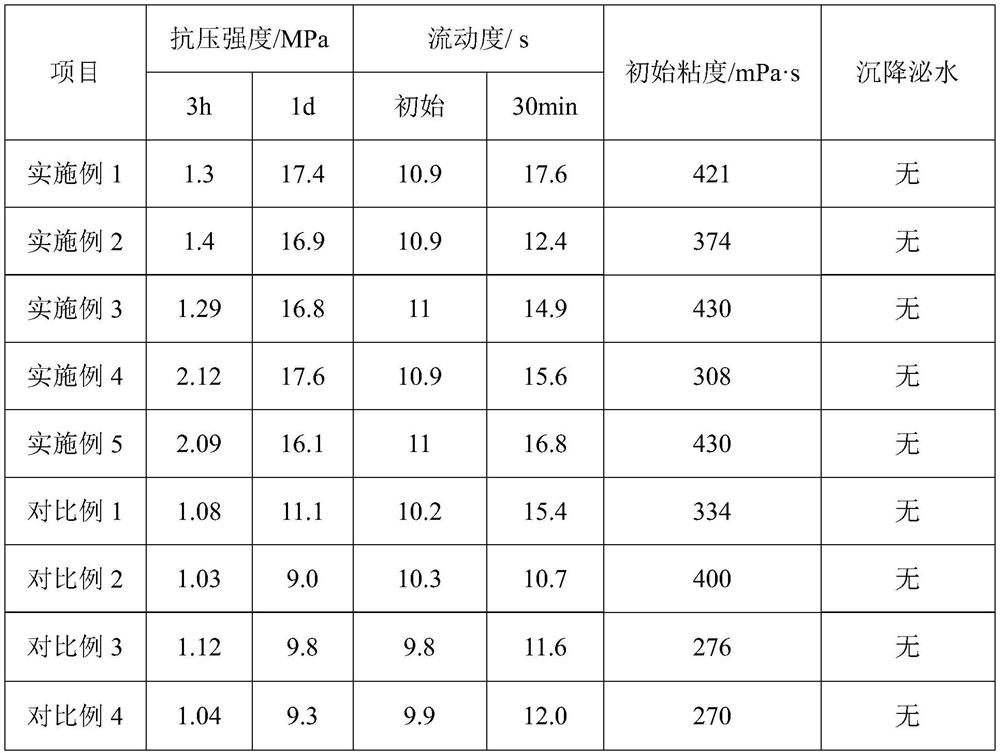

Examples

Embodiment 1

[0021] This embodiment provides a kind of grouting material for reinforcement of medium-coarse sand layer. The raw materials are calculated in parts by mass, including 40 parts of slag micropowder, 24 parts of water, 0.24 parts of water reducer, 1.6 parts of sodium hydroxide, and 1.6 parts of sodium carbonate. , 0.6 parts of calcium hydroxide and 0.5 parts of calcium formate; the slag powder is S95 grade, the water reducer is Sika high-efficiency water reducer, and sodium hydroxide, sodium carbonate, calcium hydroxide and calcium formate are industrially pure.

[0022] The preparation method of the grouting material for strengthening the medium-coarse sand layer specifically includes the following steps:

[0023] S1: Weigh each raw material according to the formula quantity, mix and stir the slag fine powder and the dry water reducer for 15 seconds to obtain a premix;

[0024] S2: Add 18 parts of water to the obtained premix, stir for 1 minute to obtain a premixed slurry, stir...

Embodiment 2

[0027] This embodiment provides a grouting material for medium-coarse sand layer reinforcement. The raw materials are calculated in parts by mass, including 45 parts of slag micropowder, 27 parts of water, 0.27 parts of water reducer, 1.575 parts of sodium hydroxide, and 1.35 parts of sodium carbonate. , 0.45 parts of calcium hydroxide and 0.55 parts of calcium formate; the slag powder is S95 grade, the water reducer is Sika high-efficiency water reducer, and sodium hydroxide, sodium carbonate, calcium hydroxide and calcium formate are industrially pure.

[0028] The preparation method of the grouting material for strengthening the medium-coarse sand layer specifically includes the following steps:

[0029] S1: Weigh each raw material according to the formula quantity, mix and stir the slag fine powder and the dry water reducer for 15 seconds to obtain a premix;

[0030] S2: Add 20 parts of water to the obtained premix, stir for 2 minutes to obtain a premixed slurry, stir and ...

Embodiment 3

[0033] This embodiment provides a grouting material for medium-coarse sand layer reinforcement. The raw materials include 30 parts of slag powder, 18 parts of water, 0.21 parts of water reducer, 0.9 parts of sodium hydroxide, and 0.9 parts of sodium carbonate in parts by mass. , 0.45 parts of calcium hydroxide, 0.3 parts of calcium formate; the slag powder is S95 grade, the water reducer is Sika high-efficiency water reducer, and sodium hydroxide, sodium carbonate, calcium hydroxide and calcium formate are industrially pure.

[0034] The preparation method of the grouting material for strengthening the medium-coarse sand layer specifically includes the following steps:

[0035] S1: Weigh each raw material according to the formula quantity, mix and stir the slag fine powder and the dry water reducer for 18 seconds to obtain a premix;

[0036] S2: Add 14 parts of water to the obtained premix, stir for 2 minutes to obtain a premixed slurry, stir and dissolve sodium hydroxide, sod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com