A kind of printed circuit board base material processing device and processing method

A technology of printed circuit boards and basic materials, which is applied in the directions of printed circuits, printed circuit manufacturing, and processing of insulating substrates/layers, etc. It can solve problems such as burnt edges of circuit substrates, cost waste, and affect product quality, and achieve cost savings. , the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

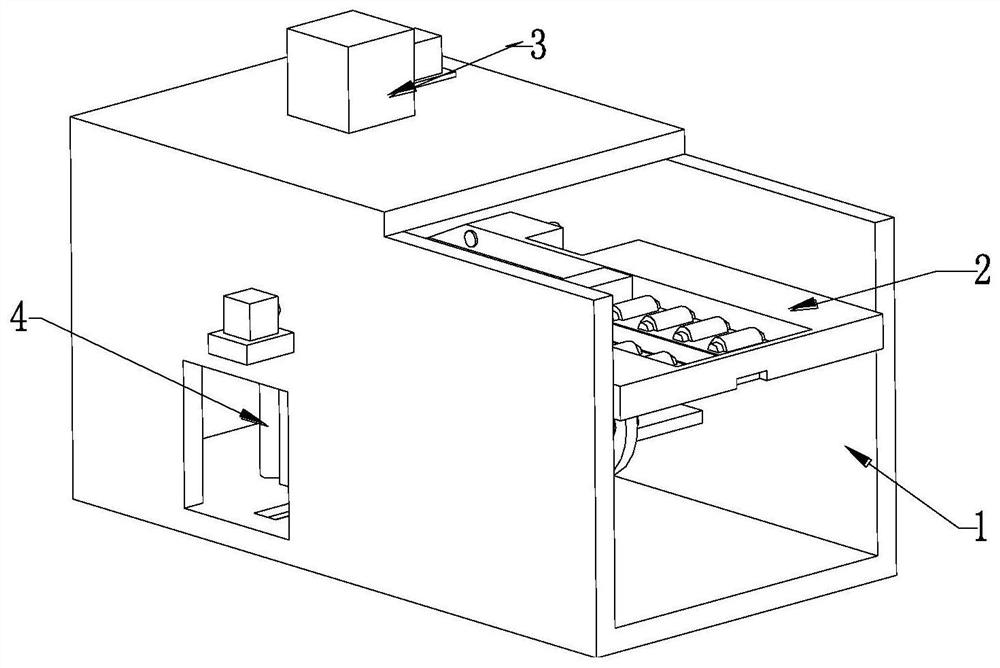

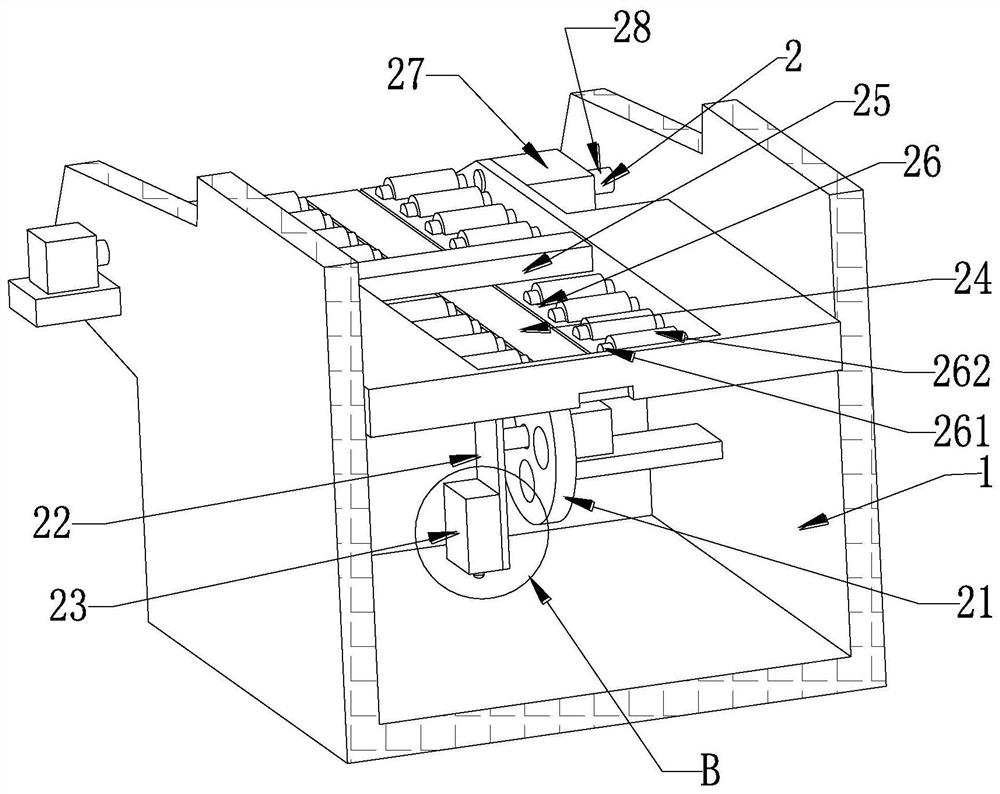

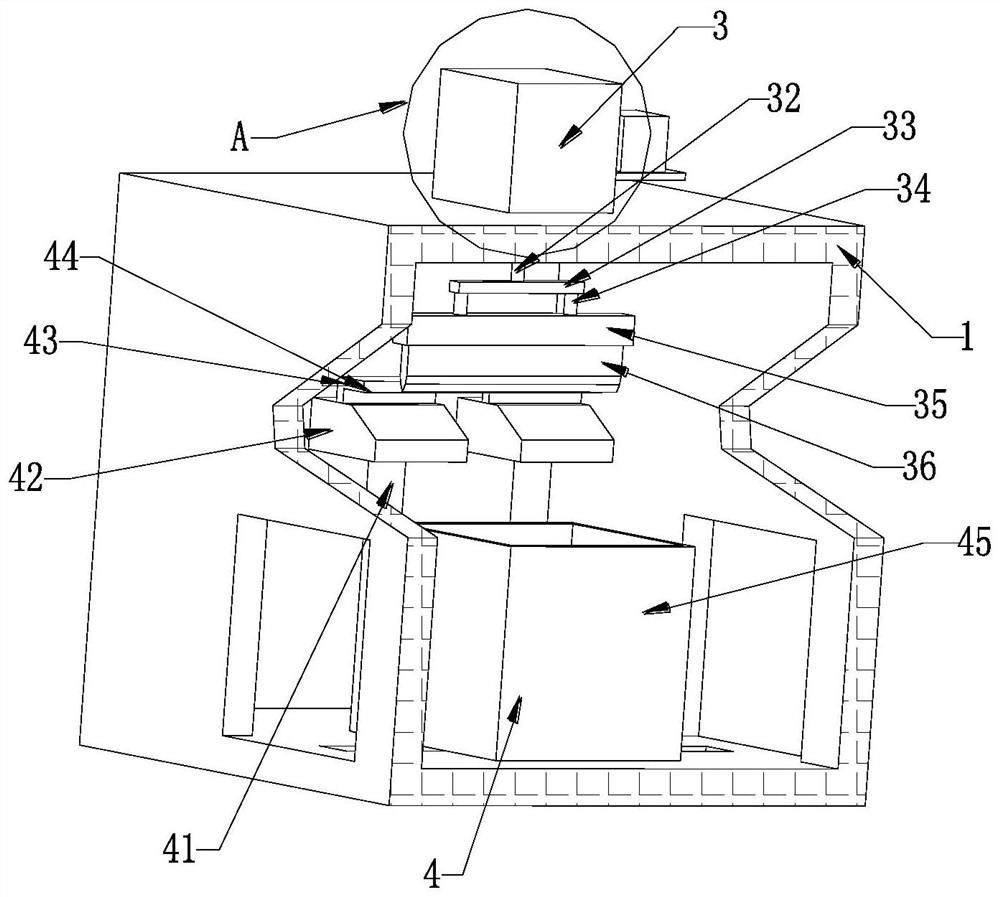

[0033] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 7 , to further elaborate the present invention.

[0034]A printed circuit board basic material processing device includes a mounting frame 1, a feeding set 2, a cutting set 3, and a receiving set 4, and the mounting frame 1 is provided with a feeding set 2, a cutting set 3, and a receiving set in sequence from left to right. Kit 4, of which:

[0035] The feeding kit 2 includes a No. 1 motor, a rotating flywheel 21, a rotating connecting plate 22, an intermittent block 23, a sliding bar 24, a material resisting block 25, a support plate 26, an edging box 27 and an edging mechanism 28, and the No. 1 motor Installed on the outer wall of the mounting frame 1 through the motor base, a rotating flywheel 21 is installed on the output shaft of the No. 1 motor, and the rear end of the rotating flywheel 21 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com