Bionic bimetallic band saw blade

A bimetal band and saw blade technology, which is applied to metal sawing equipment, metal processing equipment, sawing machine tools, etc., can solve the problems of low cutting speed and cutting efficiency, high impact force of teeth, and short service life of saw blades. High cutting efficiency, sharp saw teeth, and long service life of the saw blade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

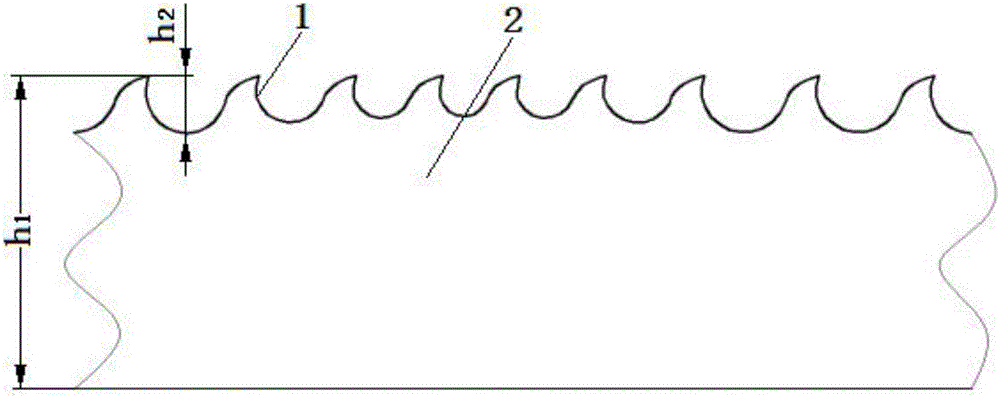

[0029] Example 1: A bionic equal-tooth bimetallic band saw blade

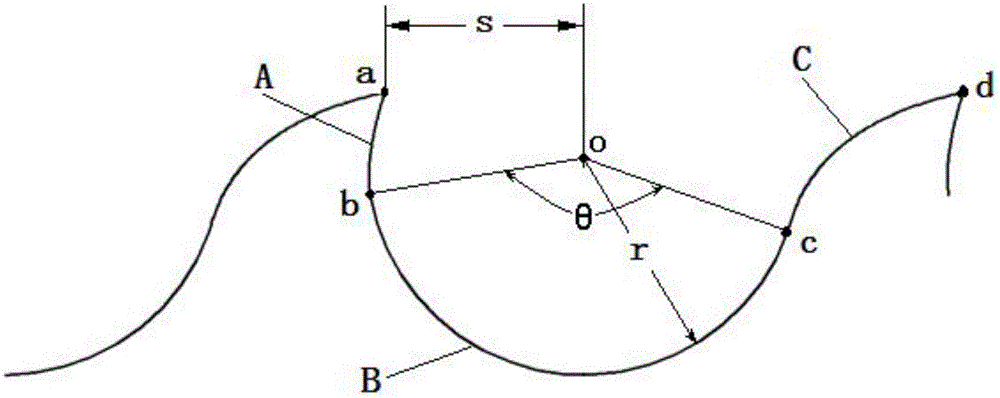

[0030] The bionic bimetallic band saw blade involved in the present invention comprises a saw tooth 1 and a saw blade body 2, the tooth material is made of M42 high-speed steel, and the saw blade body material is made of Rm80 steel. The sawtooth 1 and the saw blade body 2 are fixedly integrated, and the said sawtooth 1 has the geometric structure characteristics of a badger’s canine tooth, wherein the sawtooth 1 is formed by sequentially and smoothly connecting four points a, b, c, and d, where the two points a and b are connected by a line The curve A of the front part of the tooth shape; the line connecting two points b and c is the tooth bottom arc line B; the line connecting two points c and d is the back curve C of the tooth shape;

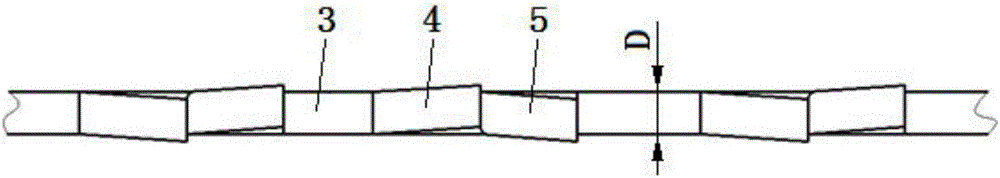

[0031] The adopted form of teeth division is improved oblique teeth division, and the form of sawtooth division teeth is 4 left division teeth, 5 division teeth right, 4 divis...

example 2

[0036] Example 2: A bionic 3 / 4 variable tooth bimetallic band saw blade

[0037] The bionic bimetallic band saw blade involved in the present invention comprises a saw tooth 1 and a saw blade body 2, the tooth material is made of M42 high-speed steel, and the saw blade body material is made of Rm80 steel. The sawtooth 1 and the saw blade body 2 are fixedly integrated, and the said sawtooth 1 has the geometric structure characteristics of a badger’s canine tooth, wherein the sawtooth 1 is formed by sequentially and smoothly connecting four points a, b, c, and d, where the two points a and b are connected by a line It is the front curve A of the tooth shape; the line connecting two points b and c is the tooth bottom arc line B; the line connecting two points c and d is the back curve C of the tooth shape.

[0038] The 5 single teeth of the bionic bimetallic band saw blade form a cyclic tooth pitch, and the tooth division form adopted is an improved oblique tooth division form. ...

example 3

[0044] Example 3: A bionic 2 / 3 variable tooth bimetallic band saw blade

[0045] The bionic bimetallic band saw blade involved in the present invention comprises a saw tooth 1 and a saw blade body 2, the tooth material is made of M42 high-speed steel, and the saw blade body material is made of Rm80 steel. The sawtooth 1 and the saw blade body 2 are fixedly integrated, and the said sawtooth 1 has the geometric structure characteristics of a badger’s canine tooth, wherein the sawtooth 1 is formed by sequentially and smoothly connecting four points a, b, c, and d, where the two points a and b are connected by a line It is the front curve A of the tooth shape; the line connecting two points b and c is the tooth bottom arc line B; the line connecting two points c and d is the back curve C of the tooth shape.

[0046] The bionic bimetallic band saw blade has 8 single sawtooths to form a cyclic tooth pitch, and the tooth division form adopted is an improved oblique tooth division saw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tooth depth | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com