Small dustless ceramic tile cutter

A cutting machine and ceramic tile technology, applied in stone processing tools, work accessories, manufacturing tools, etc., can solve problems such as affecting the physical and mental health of workers, deteriorating the operating environment of workers, and weak awareness of protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

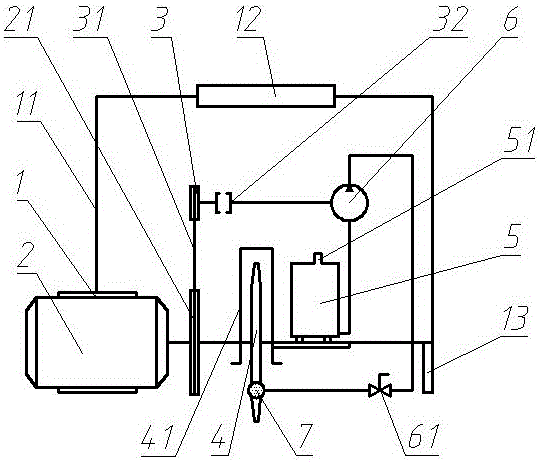

[0009] A small dust-free tile cutting machine of the present invention will be further described below in conjunction with the accompanying drawings:

[0010] Depend on figure 1 It can be seen that a small dust-free tile cutting machine of the present invention includes a mounting frame 1, a motor 2, a driven wheel 3, a cutting piece 4, a water tank 5, a water pump 6 and a nozzle 7, and the motor 2 is arranged in the mounting frame 1 , the output shaft of the motor 2 is provided with a drive wheel 21, the other side of the drive wheel 21 is provided with a cutting piece 4, the top of the cutting piece 4 is provided with a dust cover 41, the dust cover The outside of 41 is provided with water tank 5, and the top of water tank 5 is provided with water inlet 51; Described driven wheel 3 is connected with driving wheel 21 by transmission belt 31, and one side of driven wheel 3 is connected with water pump 6 by clutch 32, so The inlet of the water pump 6 is connected to the bottom...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap