High precision dual-power 3D printer, printing method and installation method of the printer

A 3D printer and dual power technology, applied in the direction of additive processing, etc., can solve the problems of low processing precision, high cost, easy deformation, etc., and achieve the effect of high space utilization, fast installation speed and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

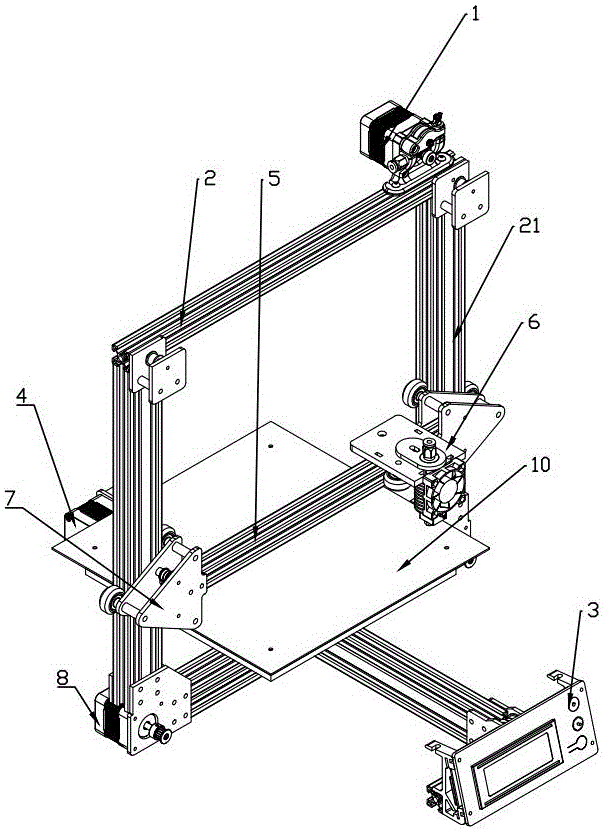

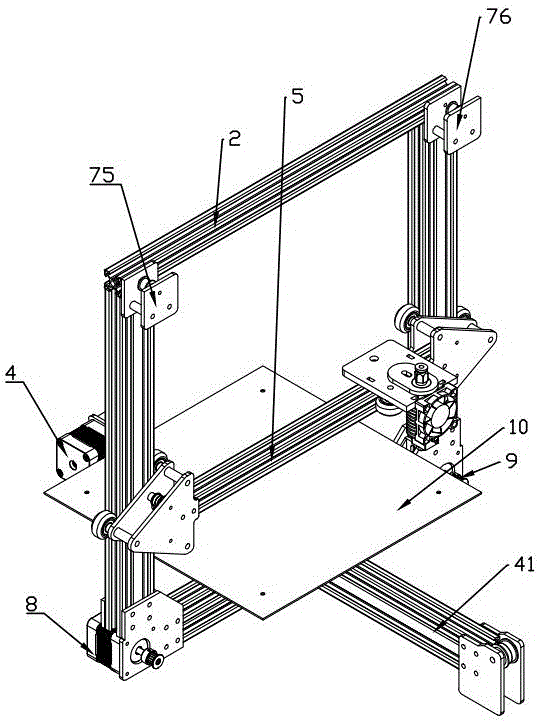

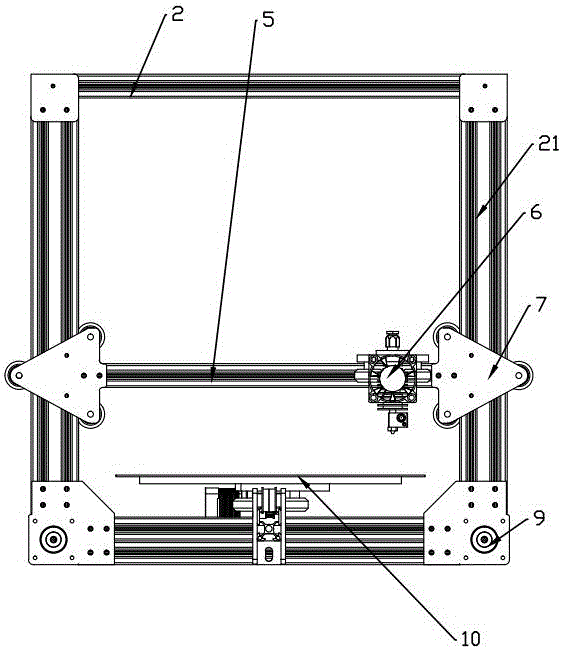

[0056] Embodiment 1: A dual-power 3D printer with high precision, see Figure 1 to Figure 15 , including a gantry-type support, the gantry-type support includes columns 21 on both sides and a crossbeam 5 that is slidingly connected to the uprights 21, and the printer also includes a printing table 10 below the upright column 21, a nozzle that is slidably installed on the crossbeam 5, and a nozzle for the nozzle A feeding device 1 for providing raw materials, a Y-direction driving device for controlling the movement of the printing table 10 in the Y direction is installed under the printing table 10, and a bidirectional moving device for driving the nozzle to move in the X-axis and Z-axis directions is installed on the gantry-shaped support;

[0057] The two-way moving device includes a synchronous pulley, which is wound around the synchronous pulley to form a " The synchronous belt 72 of " shape closed-loop connection, and the stepper motor at the bottom of the columns 21 on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com