Shuttle vehicle positioning system and control method

A shuttle, industrial control technology, applied in conveyor control devices, conveyor objects, conveyors, etc., can solve the problems of affecting the counting of encoders, high cost, and inapplicability of circular tracks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the embodiments of the accompanying drawings.

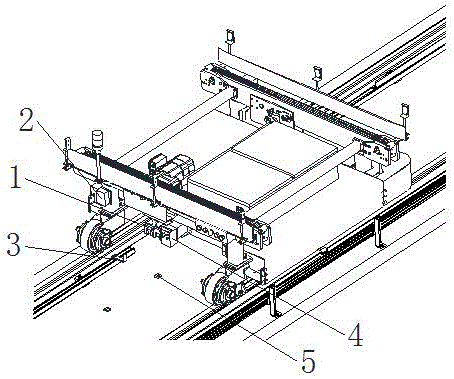

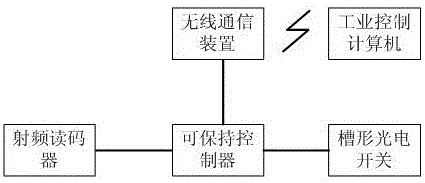

[0022] Such as figure 1 As shown, the shuttle car positioning system includes a radio frequency code reader 4, a code carrier 5, a slot photoelectric switch 1, an address chip 3, a wireless communication device 2, an industrial control computer, a programmable controller, and a shuttle car. The radio frequency code reader 4 and the groove-type photoelectric switch 1 are installed at the bottom of the shuttle car, the code carrier 5 and the address identification sheet 3 are installed near the track, and a code carrier is arranged on the track 3 to 4 meters away from the loading platform and unloading platform 5, the code carrier 5 and the address identification chip 3 are arranged at the loading platform and the unloading platform. Each code carrier 5 is provided with different numbers. The shuttle car is installed on the running track. The progra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com