Deoiling device

An oil tank and oil rod technology, which is used in grease/oily substance/float removal devices, adsorbed water/sewage treatment, liquid separation, etc., can solve the problem of difficult to control the recovery ratio, easy blocking of filters, and improper waste oil recovery and treatment. and other problems to achieve the effect of reducing friction and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

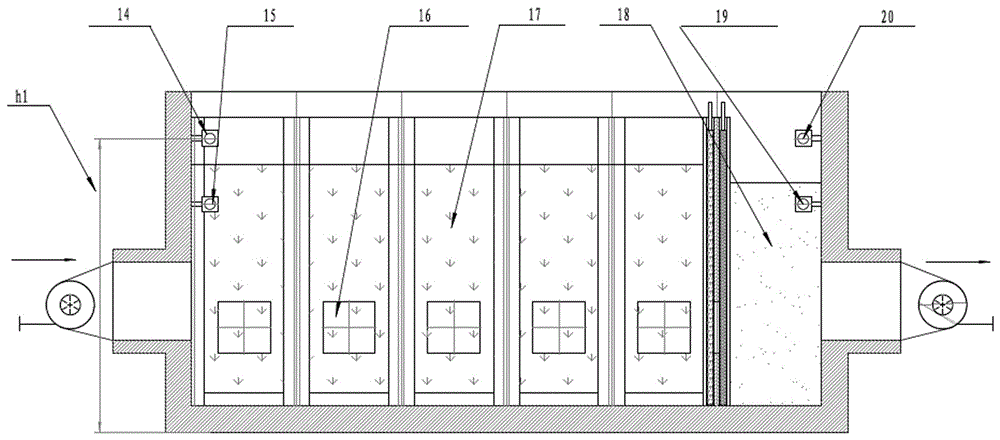

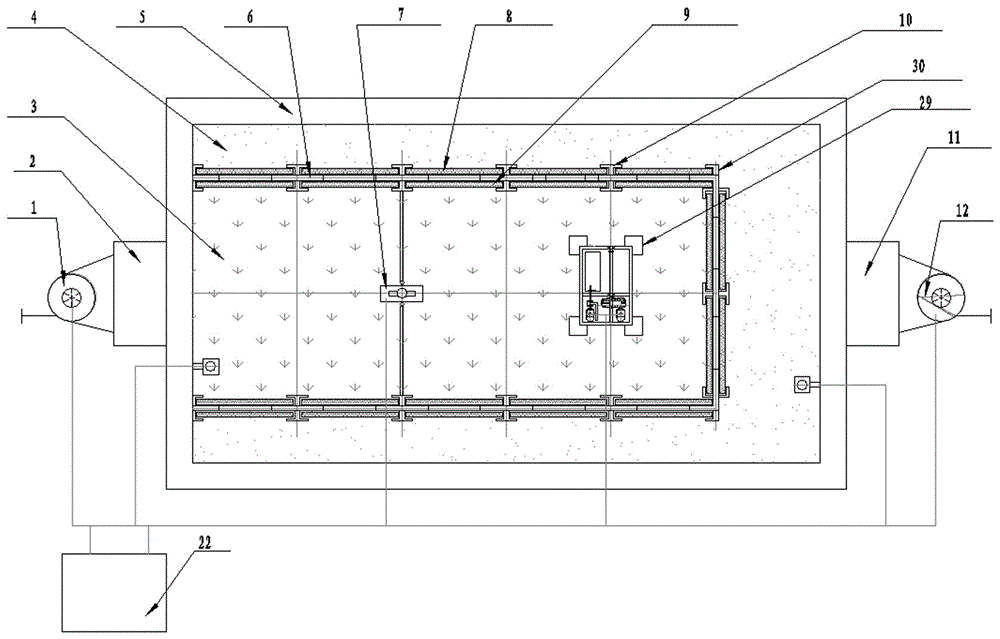

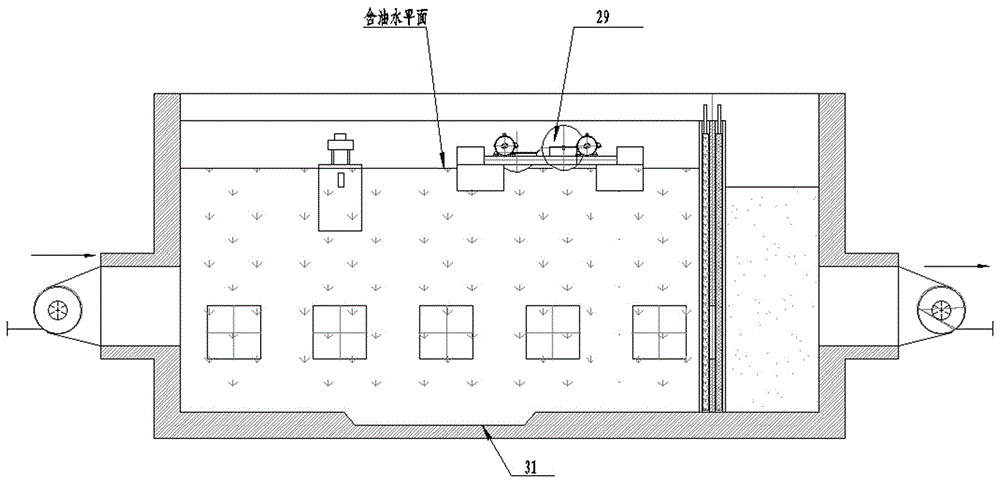

[0025] Such as Figure 1 to Figure 4 As shown, an oil-water separation device, the oil-water separation device includes a box body I5, a box body II6 is arranged in the box body I5, and the box body I5 and the box body II6 have no common wall, so that the box body II6 forms oily waste The water tank 3 and the tank I5 form a clean water tank 4, and an oily waste water 17 channel is set between the water inlet and the oily waste water tank 3, and the oily waste water 17 enters the oily waste water tank 3 through the channel.

[0026] When the tank body II6 is installed in the tank body I5, the tank body I5 and the tank body II6 have a common wall on the side of the water inlet, and the oily wastewater 17 enters the oily wastewater tank 3 from the water inlet.

[0027] Channels are set on the wall of the box body II6 not shared with the box body I5, and channels 30 are set on the other walls of the box body II6, so that the oily waste water tank 3 and the clean water tank 4 are c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com