High-concentration wastewater treatment technology and treatment production line

A treatment process and technology for concentrated wastewater, applied in the field of wastewater treatment, can solve the problems of not infinite processing capacity, high treatment cost, and troublesome wastewater treatment plants, so as to improve wastewater treatment efficiency, reduce wastewater treatment costs, and save use. amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The high-concentration wastewater treatment process of the embodiment of the present invention is used to simultaneously treat high-concentration acid wastewater and high-concentration alkaline wastewater. The high-concentration wastewater treatment process includes the following steps:

[0047] Dilution step: mixing high-concentration acidic wastewater and low-concentration acidic wastewater into suitable concentrated acidic wastewater, mixing high-concentrated alkaline wastewater and low-concentrated alkaline wastewater into suitable concentrated alkaline wastewater, the high concentration refers to dichromate The index is 200-500 mg / L, the low concentration means that the dichromate index is 0-50 mg / L, and the appropriate concentration means that the dichromate index is 50-150 mg / L;

[0048] Mixing step: mixing suitable concentrated acidic wastewater and suitable concentrated alkaline wastewater into comprehensive wastewater;

[0049] Wastewater pH adjustment step: a...

Embodiment 2

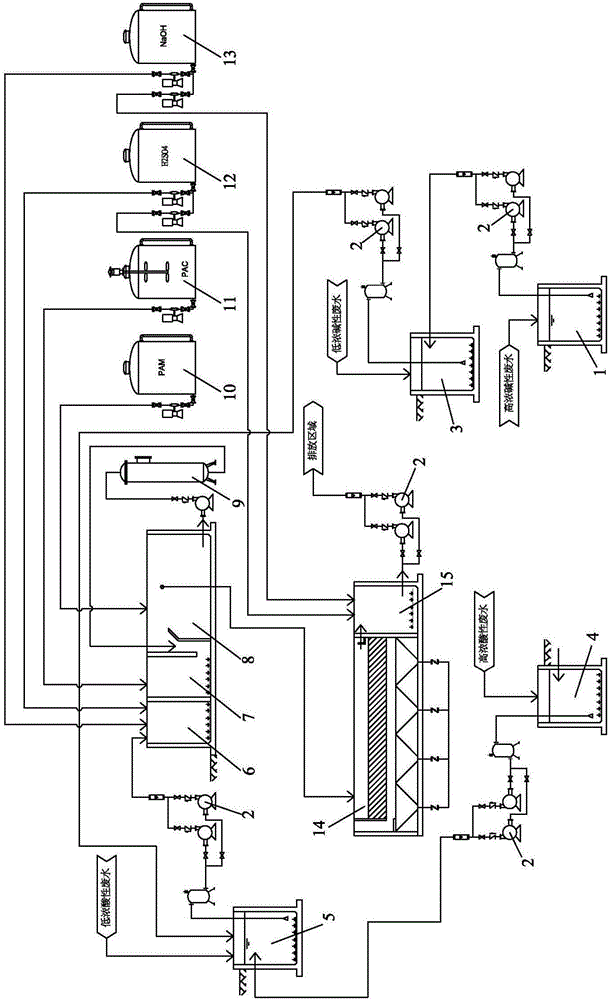

[0058] The high-concentration wastewater treatment line of the embodiment of the present invention is used to treat high-concentration acid wastewater and high-concentration alkaline wastewater at the same time, see figure 1 , the treatment line of the high-concentration wastewater is provided in turn according to the treatment process: a dilution pool for mixing high-concentration alkaline wastewater and low-concentration alkaline wastewater into suitable concentrated alkaline wastewater. Mixing with low-concentration acidic wastewater into suitable concentrated acidic wastewater, and then mixing the suitable concentrated acidic wastewater and the suitable concentrated alkaline wastewater into comprehensive wastewater mixing pool 5, used to add alkaline solution and / or acid to comprehensive wastewater The solution is to adjust the comprehensive wastewater to a neutral wastewater pH value adjustment tank 6. It is used to add a flocculant to the comprehensive wastewater so that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com