Anticorrosion and flame-retardant plastic

A technology of flame-retardant plastics and flame retardants, which is applied in the field of anti-corrosion and flame-retardant plastics, can solve the problems of reducing the safety of plastics, failing to achieve antibacterial and anti-corrosion, and poor antibacterial effects, and achieve improved compatibility, small mechanical properties, long-lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

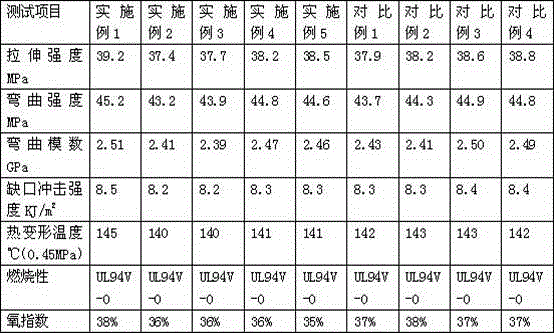

Examples

Embodiment 1

[0015] An anti-corrosion and flame-retardant plastic, which consists of the following components by weight: 95 parts of ABS, 85 parts of PC, 12 parts of mica powder, 10 parts of quartz sand, 25 parts of flame retardant, 11 parts of carbon black, 12 parts of soybean oil, 10 parts of corn flour, 5 parts of antibacterial preservative. Among them, the flame retardant is composed of antimony trioxide, dimethyl trimethylsilyl phosphonate, chlorinated paraffin and molybdenum trioxide in a weight ratio of 3:2:1.5:1.5, and the antibacterial antiseptic is composed of silver zeolite , chitosan, and pomegranate peel extract are mixed in a weight ratio of 4:1.5:1.5.

[0016] The products prepared in this example were tested by industry standard experiments, and the results were as follows: the 24-hour sterilization rate of Escherichia coli reached 99.4%, and the 24-hour sterilization rate of Staphylococcus aureus reached 99.8%.

Embodiment 2

[0018] An anti-corrosion and flame-retardant plastic, consisting of the following components in parts by weight: 90 parts of ABS, 95 parts of PC, 10 parts of mica powder, 12 parts of quartz sand, 20 parts of flame retardant, 12 parts of carbon black, 8 parts of soybean oil, 12 parts of corn flour, 3 parts of antibacterial preservatives. Among them, the flame retardant is composed of antimony trioxide, dimethyl trimethylsilyl phosphonate, chlorinated paraffin and molybdenum trioxide in a weight ratio of 2:3:1:2, and the antibacterial antiseptic is composed of silver zeolite , chitosan, and pomegranate peel extract are mixed in a weight ratio of 4:1.5:1.5.

[0019] The products prepared in this example were tested by industry standard experiments, and the results were as follows: the 24-hour sterilization rate of Escherichia coli reached 98.1%, and the 24-hour sterilization rate of Staphylococcus aureus reached 99.3%.

Embodiment 3

[0021] An anti-corrosion and flame-retardant plastic, which consists of the following components by weight: 100 parts of ABS, 75 parts of PC, 15 parts of mica powder, 6 parts of quartz sand, 30 parts of flame retardant, 10 parts of carbon black, 16 parts of soybean oil, 6 parts of corn flour, 6 parts of antibacterial preservatives. Among them, the flame retardant is composed of antimony trioxide, dimethyl trimethylsilyl phosphonate, chlorinated paraffin and molybdenum trioxide in a weight ratio of 4:1:2:1, and the antibacterial antiseptic is composed of silver zeolite , chitosan, and pomegranate peel extract are mixed in a weight ratio of 5:1:2.

[0022] The products prepared in this embodiment were tested by standard experiments in the industry, and the results were as follows: the 24-hour sterilization rate of Escherichia coli reached 98.5%, and the 24-hour sterilization rate of Staphylococcus aureus reached 99.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com