Construction method for controlling cracks in deep-buried circular culvert of mountain road

A construction method and technology of pipe culverts, which can be applied to the bottom layer of roads, buildings, etc., can solve the problems of round pipe culvert cracking, embankment collapse, and exceeding the design load range, and achieve the effect of preventing cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

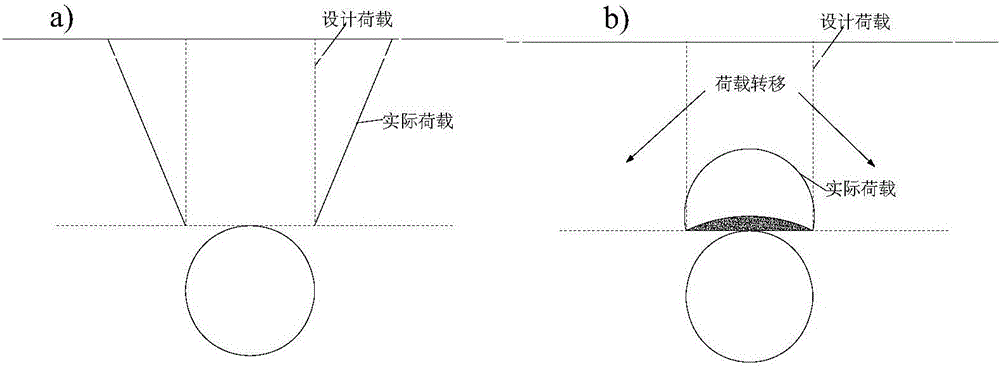

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

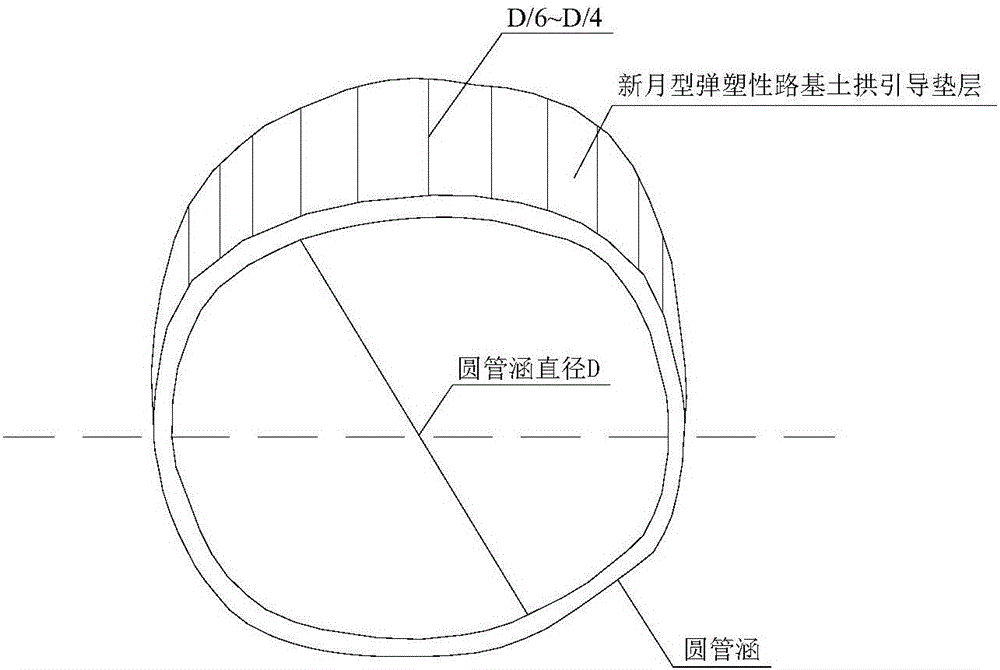

[0042] The present invention will be further elaborated and illustrated below in conjunction with the accompanying drawings and specific embodiments. The technical features of the various implementations in the present invention can be combined accordingly on the premise that there is no conflict with each other.

[0043] A construction method for controlling cracks of a deep-buried garden pipe culvert on a mountain road, the steps are as follows:

[0044] (1) Clean up debris on the surface of the foundation;

[0045] According to the measurement of the roadbed range, clean up the debris on the surface of the foundation, such as topsoil, vegetation, etc., in preparation for filling the roadbed.

[0046] (2) Layer-by-layer filling of the roadbed to the height of the top of the garden pipe culvert;

[0047] According to the requirements of the subgrade specification, it shall be rolled in layers every 50 cm thick, and the subgrade shall be filled to the design height of the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com