Semi-trailer independent type under-pressure well repairing operation machine

A technology of working under pressure and working machine, applied in drilling equipment, drill pipe, casing, etc., can solve the problems of long connection time and many auxiliary equipment, and achieve the effect of saving preparation time and good maneuverability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention.

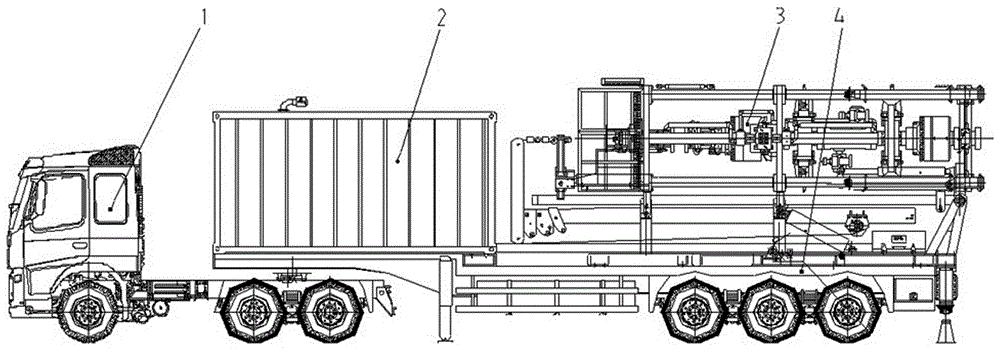

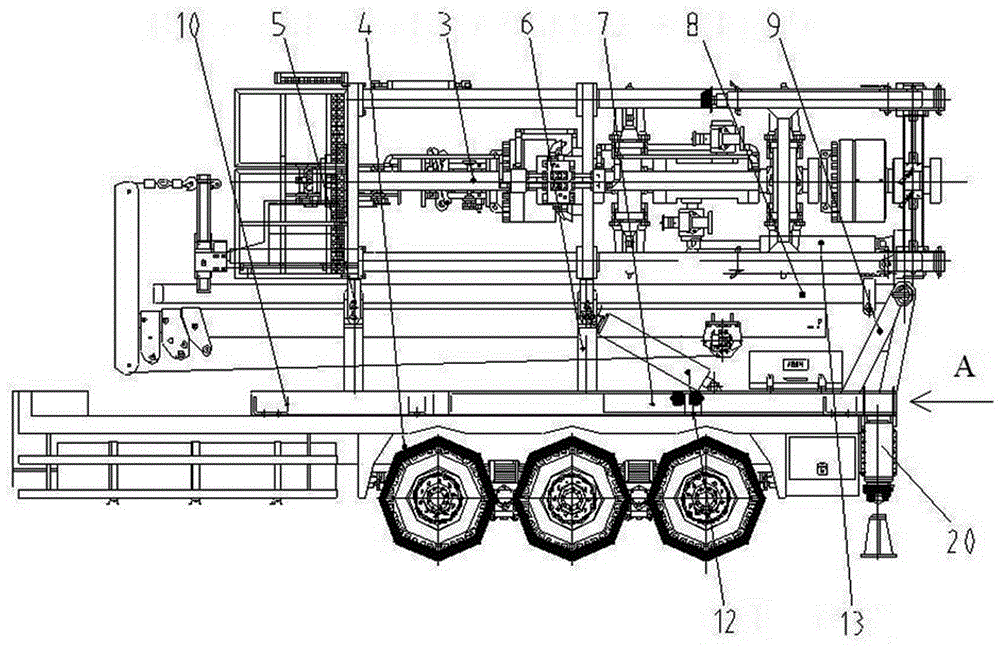

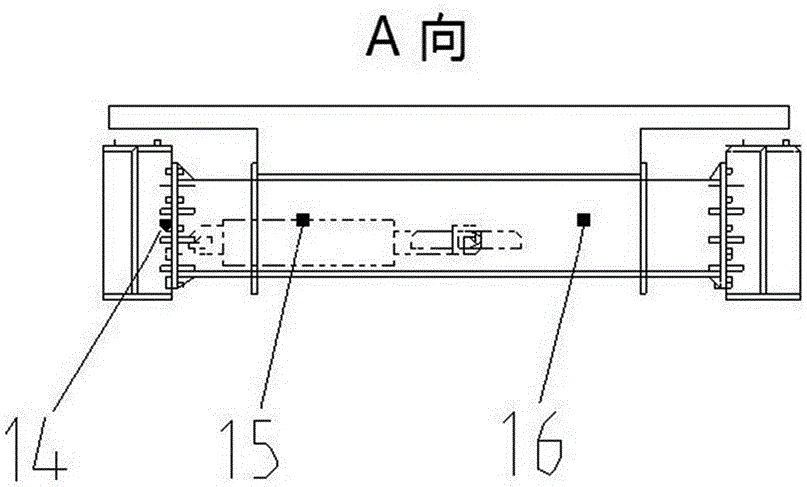

[0029] Such as Figure 1-8 The shown semi-trailer stand-alone snubbing workover machine includes tractor 1, hydraulic power unit 2, snubbing device 3, self-aligning wellhead device and semi-trailer chassis 4,

[0030] The front end of the semi-trailer chassis 4 is connected to the tractor 1, the hydraulic power unit 2 is installed on the front half of the semi-trailer chassis 4, the automatic alignment wellhead device is installed on the rear half of the semi-trailer chassis 4, and the pressure operation device 3 is installed on the automatic alignment wellhead the top of the device.

[0031] The total traction mass of tractor 1 must reach 40 tons, and the driving form is preferably 8×4 structure to ensure the stab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com