Monorail anchoring and supporting cooperative machine for fully mechanized excavation face

a technology of mechanized excavation and monorail, which is applied in the direction of mine roof caps, shaft equipment, protective covers, etc., can solve the problems of supporting operating speed, low anchoring, and further improvement of fully-mechanized production capacity, and achieves good maneuverability of equipment, reduces the size of subsidiary transporting devices, and reduces the volume of the whole set of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057]In order to make it easy to understand the technical means, creation features, achieved purpose and effectiveness of the present invention, the following is a further detailed description of the present invention with reference to the attached drawings and the specific implementation. It should be understood that the specific embodiments described herein are merely used to explain the present disclosure but are not intended to limit the present disclosure.

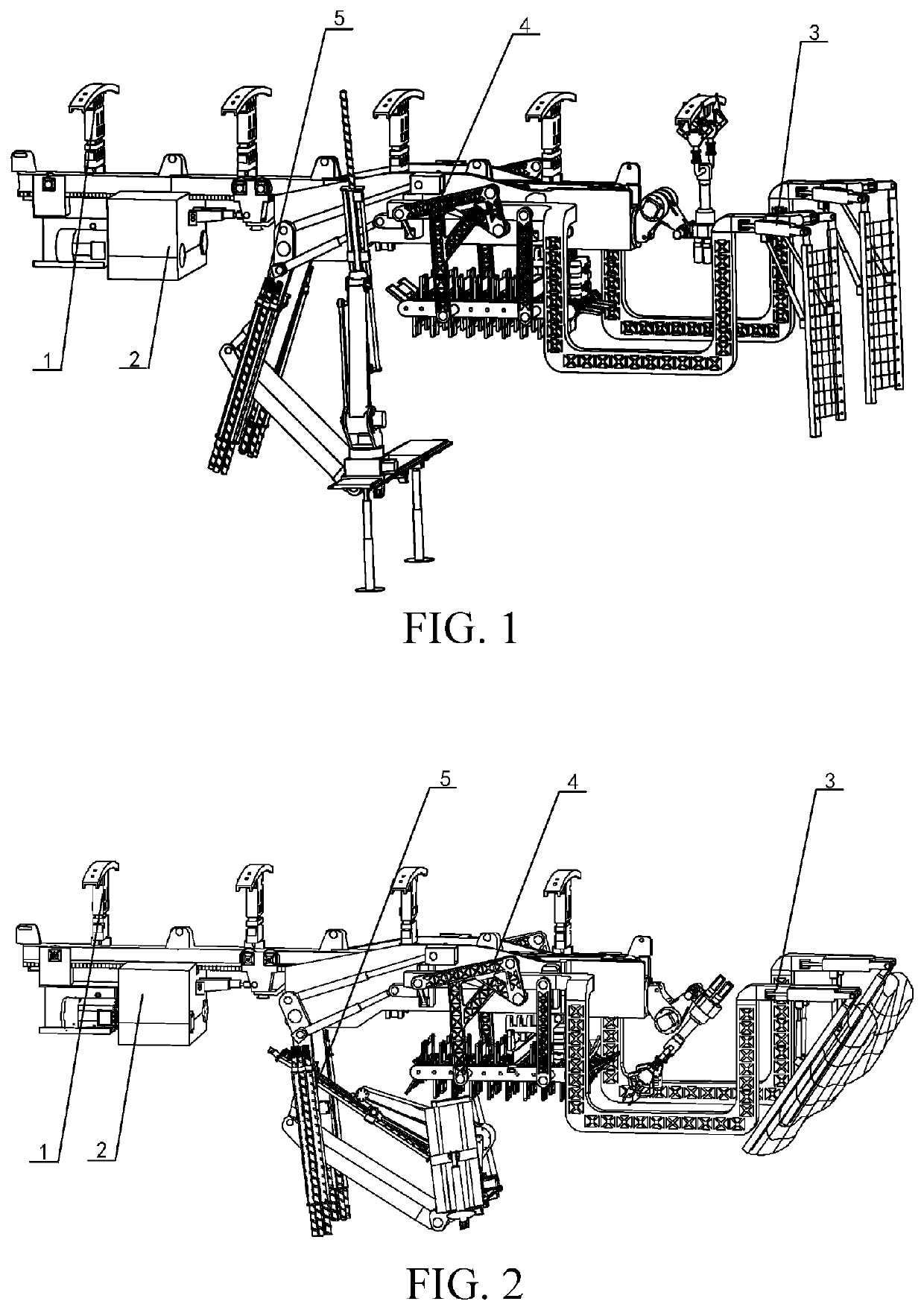

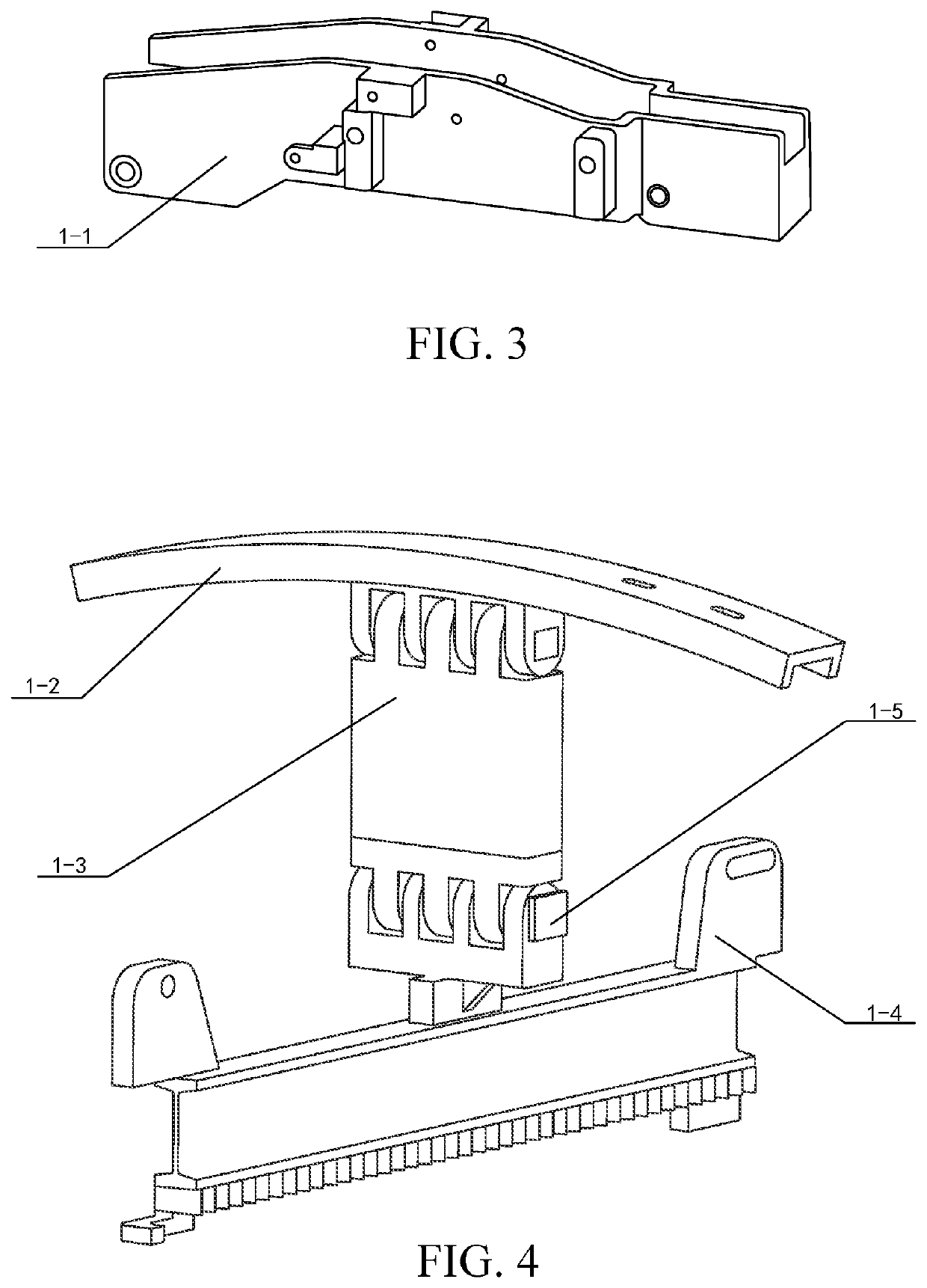

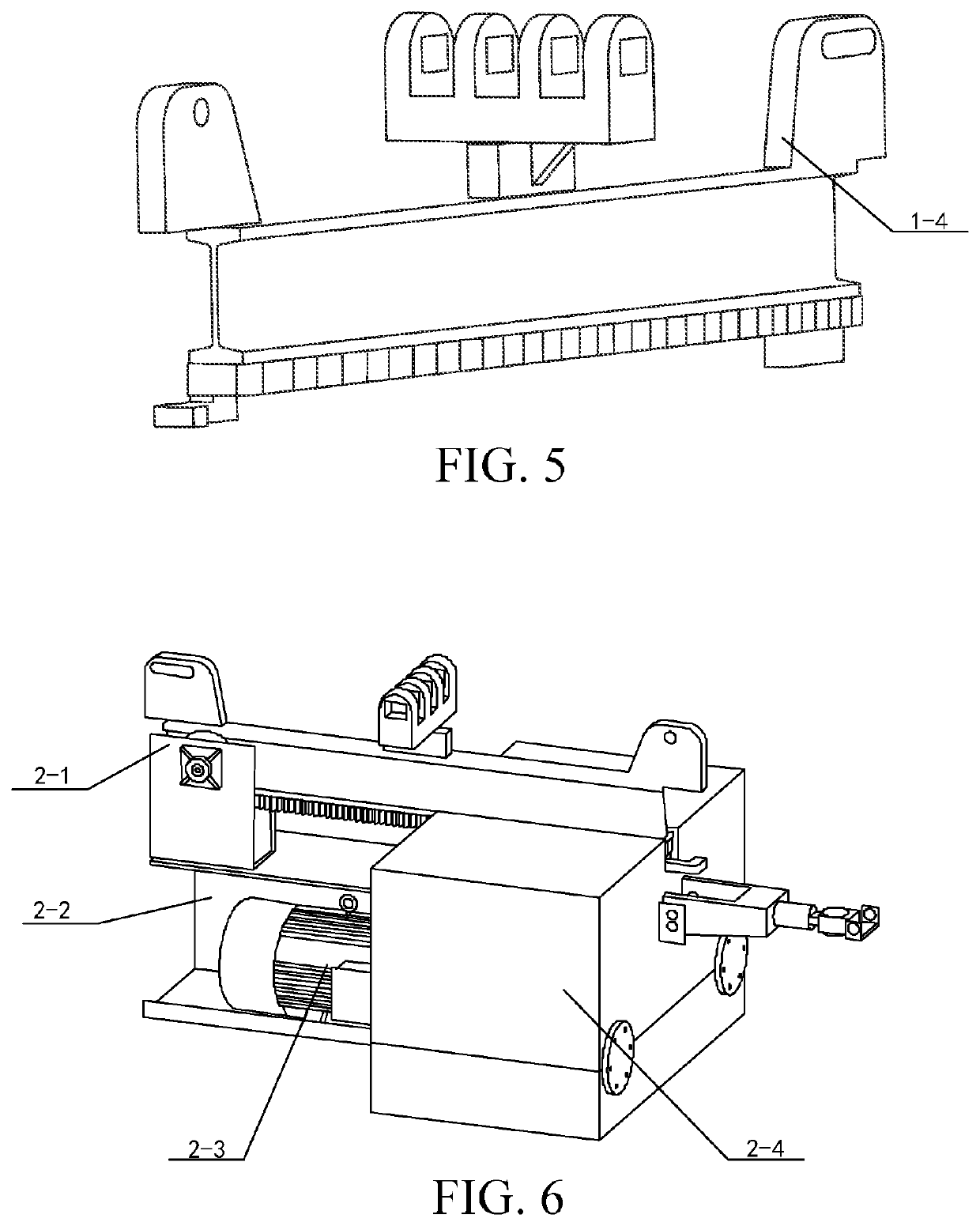

[0058]Referring to FIG. 1 and FIG. 2, a monorail anchoring and supporting cooperative machine for a fully mechanized excavation face includes a suspension support system 1, a power system 2, an advanced support system 3, a subsidiary transport system 4 and an anchoring robot system 5. The suspension support system 1 is fixed on a top end of a coal mining tunnel through an anchor rod to provide support for the whole set of equipment. The power system 2 is mounted at a tail end of a system main beam 1-1 in the suspension suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com