Roadway structure of a coal mine system

A system of roadway and roadway technology, applied in tunnels, mining equipment, earthwork drilling and other directions, can solve the problems of increased investment, high mining cost, large engineering volume and investment, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

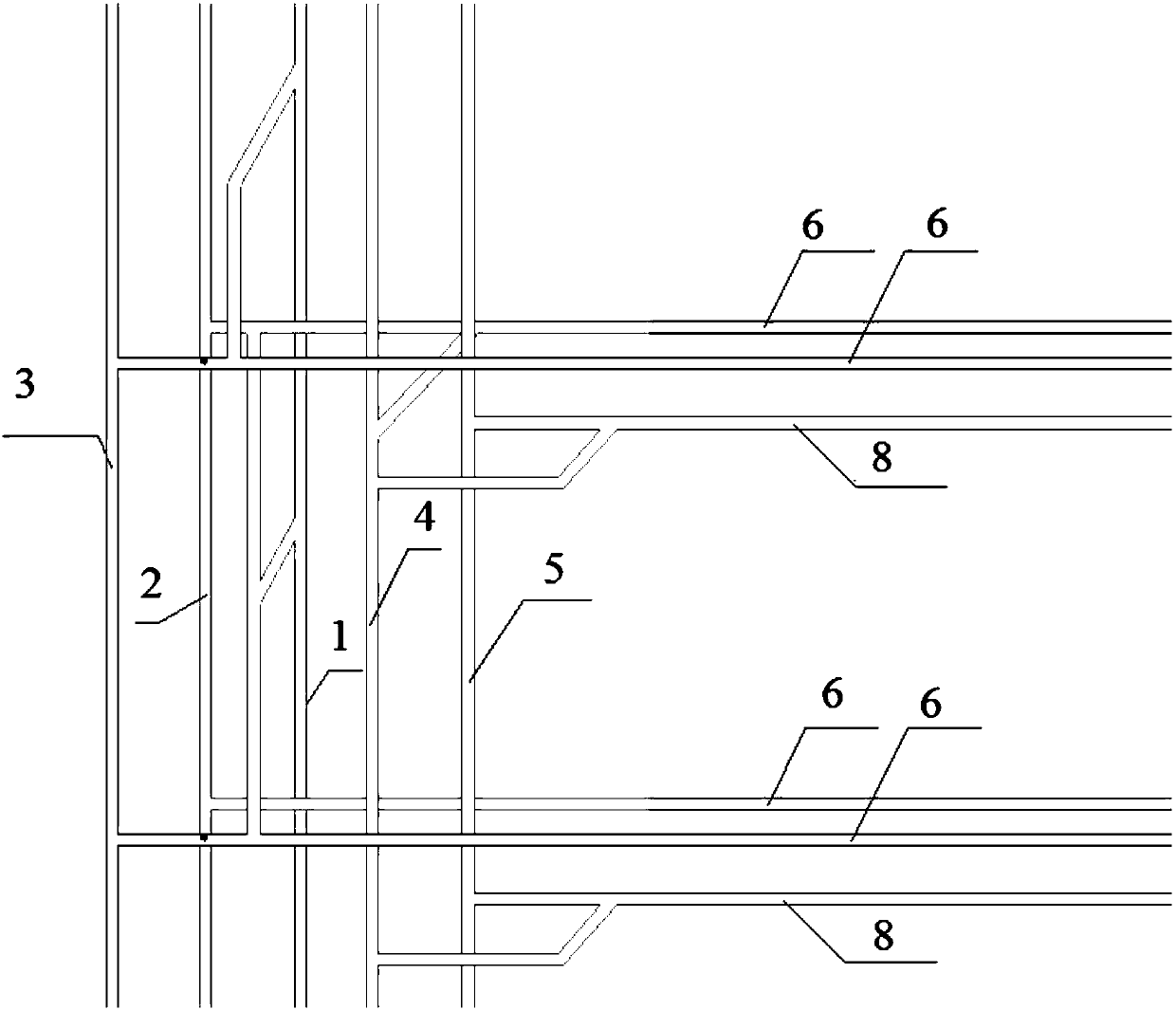

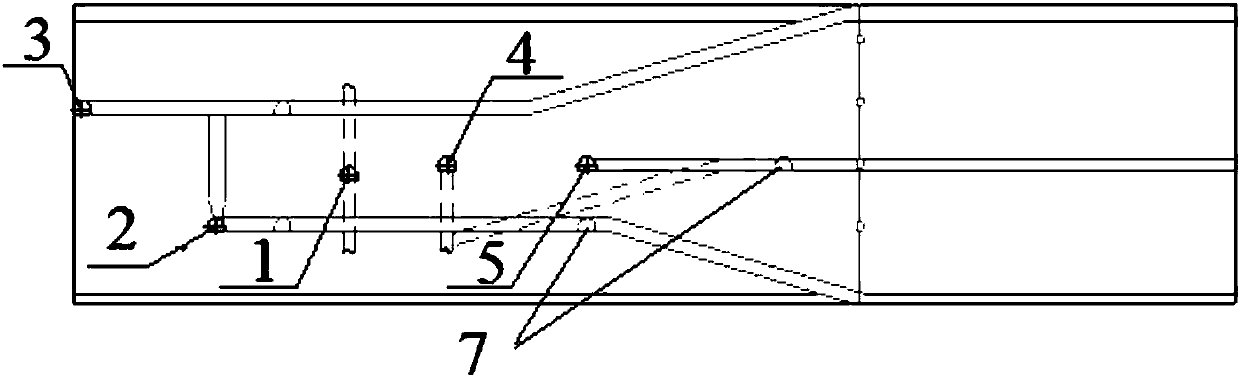

[0017] Such as figure 1 and figure 2 As shown, the roadway structure of the coal mine system of the present invention includes five system roadways that are all located between two layers of coal and are parallel to each other. The five system roadways are: track lane 1, belt conveyor lane 2, coal floor return air lane 3. Coal roof return air lane 4 and gangue belt conveyor system lane 5.

[0018] In the coal pillars of the four system lanes, track lane 1, belt machine lane 2, coal floor return air lane 3 and gangue belt conveyor system lane 5, rock lanes are used instead of coal lanes along the channel 6; the work of track lane 1 The surface is directly connected to the track lane 1 along the groove 6; the working surface of the belt machine lane 2 is connected to the belt conveyor lane 2 through the coal bunker along the groove 6; the working surface of the coal floor return air lane 3 is connected to the coal floor through the joint lane 7 Return air alley 3 connected. ...

Embodiment 2

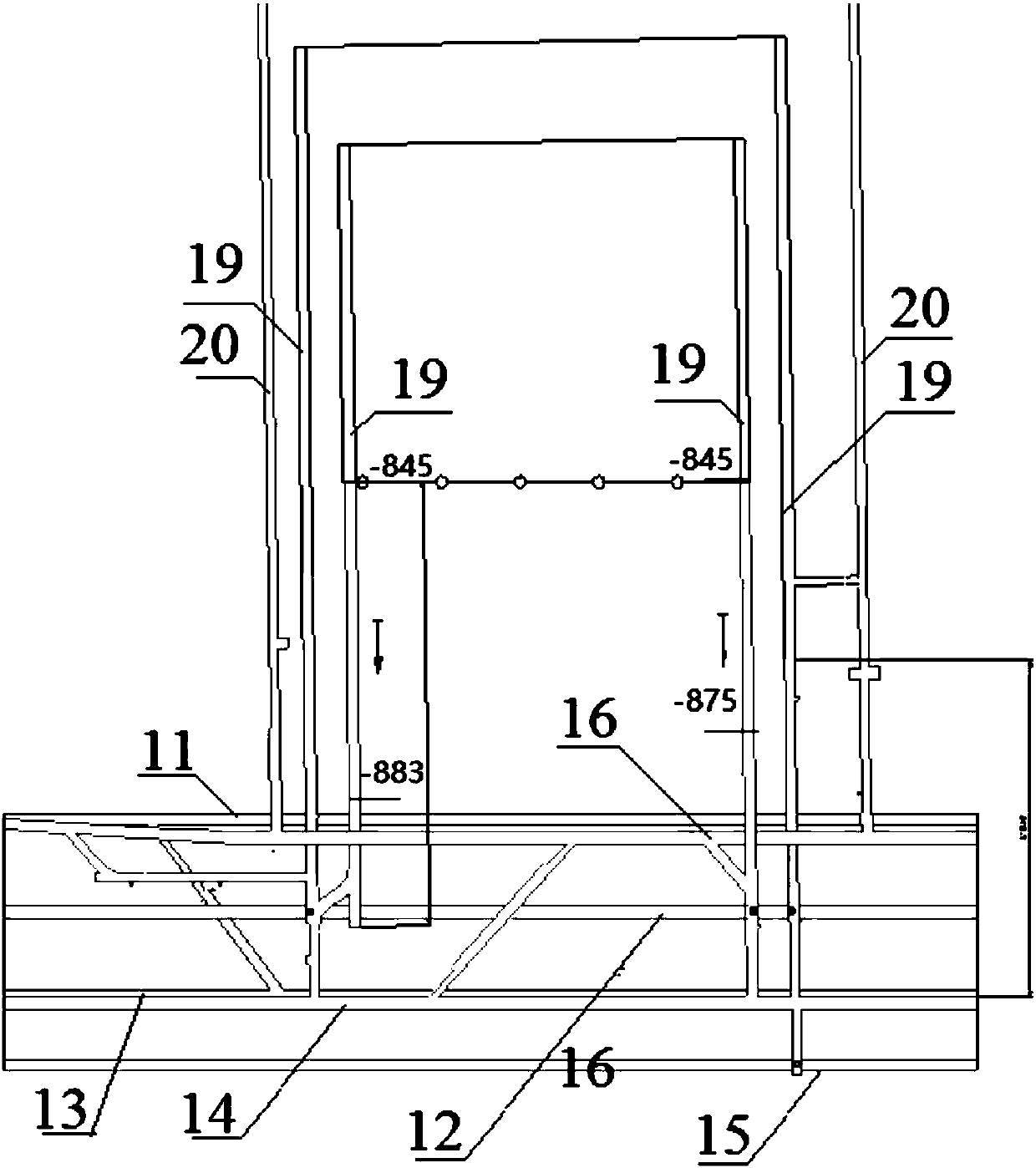

[0021] Roadway Layout of the North Panel Area of the East 1st Group C Coal in Zhuji East Coal Mine

[0022] see image 3 , the panel design adopts the governance model of 11-2 coal "one side and four lanes", so a total of 6 system lanes are arranged in this panel, from north to south are -960m11-2 coal floor return air lane 11, - 880m13-1 coal floor return air lane 16, -895m13-1 coal floor east wing belt conveyor lane 12, -965m11-2 coal floor track lane 13, -885m13-1 coal floor track lane 14 and -906m13- 1 Coal Floor Return Air Alley 15.

[0023] Achievement of benefits: Compared with the conventional layered arrangement, the coal north panel area of Dongyi group C reduces the system roadway by about 1500m, 1111 (1) working face 17 and 1111 (3) working face 18, and the trough between the closing operation line and the system roadway , the construction of rock roadway instead of 13-1 coal roadway excavation speeds up the excavation speed, reduces the drainage drilli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com