Air source energy tower system with secondary refrigerant centralized control device

A technology of centralized control device and energy tower, applied in air-conditioning systems, heating and ventilation control systems, heating and ventilation safety systems, etc., can solve the problems of difficult manual maintenance, poor automation, and high installation costs, and achieve outstanding substantive characteristics. , Reduce the overflow pipeline and water supply pipeline, and solve the effect of overflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

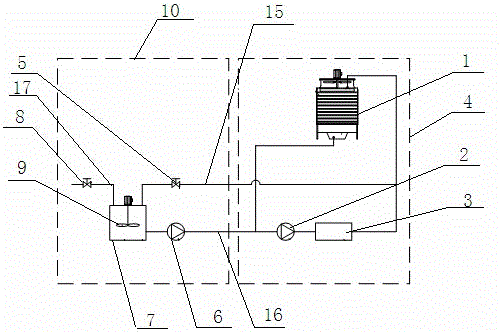

Embodiment 1

[0020] Example 1, see figure 1 , on the basis of the existing air source energy tower heat pump air conditioner 4, a refrigerant centralized control device 10 is added; the air source energy tower heat pump air conditioner 4 is composed of an energy tower 1, a refrigerant circulation pump 2 and an energy tower heat pump unit 3; The liquid outlet pipeline of the tower 1 is connected to the heat exchanger of the energy tower heat pump unit 3 through the carrier refrigerant circulating pump 2, and then to the liquid inlet pipeline of the energy tower 1, and circulates; The medicine box 7 has an inlet and an outlet on the medicine box 7. The inlet passes through the first pipeline 15 of the first valve 5, and the outlet passes through the second pipeline 16 of the rehydration pump 6, which is connected with the circulation pipe of the air source energy tower heat pump air conditioner 4. The first pipeline 15, the second pipeline 16, and the connection position of the air source en...

Embodiment 2

[0021] Example 2, see figure 1 , with the embodiment 1, the difference is that the rehydration pipeline 17 is installed on the dosing tank 7, and the rehydration pipeline 17 is connected with the tap water or the solution tank through the second valve 8; 9.

Embodiment 3

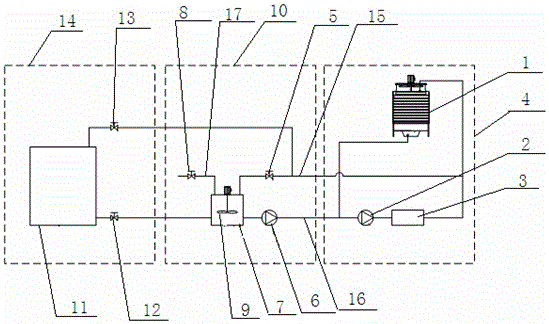

[0022] Example 3, see figure 2 , same as Embodiment 1, the difference is that in the area with high humidity, when the volume of the dosing box 7 is insufficient, a liquid collecting device 14 is installed outside the dosing box 7, and the inlet of the liquid collecting box 11 of the liquid collecting device 14 passes through the first The pipeline of the three valves 13 is connected to the first pipeline 15 or the dosing box 7 , and the outlet of the liquid collecting tank 11 is connected to the dosing box 7 or the infusion pump 6 through the pipeline of the fourth valve 12 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com