A measuring device for material wear amount and wear temperature field

A technology for measuring device and wear amount, which is applied in the direction of testing wear resistance, etc., can solve problems such as unusable, difficult replacement of parts, complicated equipment, etc., and achieve the effect of strong versatility, convenient maintenance, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

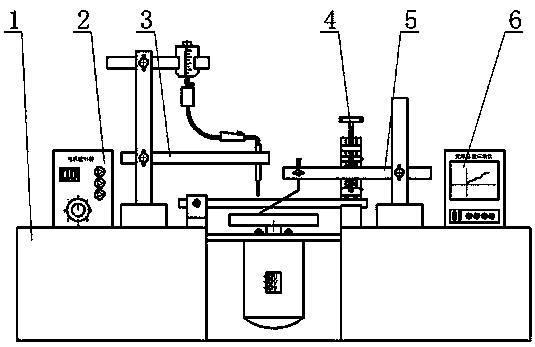

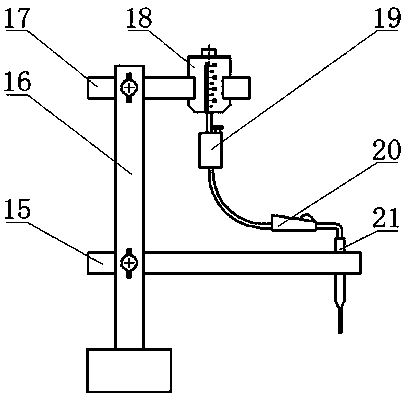

[0039] A measuring device for material wear amount and wear temperature field. Such as figure 1 As shown, the measurement device is composed of a friction mechanism 1 , a motor controller 2 , a flow control mechanism 3 , a wear measurement mechanism 4 , a temperature measurement mechanism 5 and a paperless temperature recorder 6 .

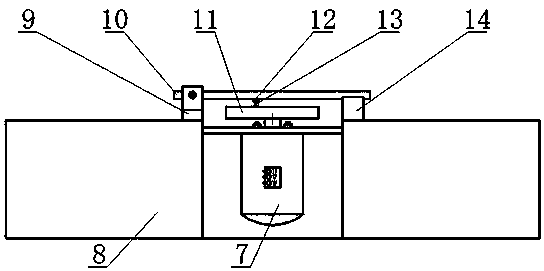

[0040] Such as figure 2As shown, the friction mechanism 1 is composed of a motor 7 , a worktable 8 , a rotatable pressure beam seat 9 , a pressure beam 10 , a grinding disc 11 , a sample fixing sleeve 12 and a pressure beam positioning plate 14 . The motor 7 is fixed on the lower plane of the panel of the workbench 8, and the motor 7 is connected with the grinding disc 11 shafts. The panel of workbench 8 is fixed with pressure beam positioning plate 14 and rotatable pressure beam seat 9, and pressure beam positioning plate 14 is positioned at the right side of millstone 11, and rotatable pressure beam seat 9 is positioned at the left side of mil...

Embodiment 2

[0051] A measuring device for material wear amount and wear temperature field. Except following situation, all the other are with embodiment 1.

[0052] The sample fixing sleeve is located directly above the 0.7~0.8 times the radius of the grinding disc.

[0053] When this embodiment is in use: the shape of the sample 13 to be measured is a cylinder with an open groove; the load loading range is 50-130N, and the wear measurement range is 1-20mm; the rotational speed of the grinding disc 11 is 64r / min or 80r One of / min; the temperature measurement range is 200~1100℃.

[0054] Compared with the prior art, this specific embodiment has the following positive effects:

[0055] This specific embodiment consists of a friction mechanism 1 , a motor controller 2 , a flow control mechanism 3 , a wear measurement mechanism 4 , a temperature measurement mechanism 5 and a paperless temperature recorder 6 . By adjusting the rotation speed of the motor 7, the flow rate of the lubricant, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com