Friction wear testing device for high-pressure seawater environment

A friction and wear test, seawater technology, applied in the direction of testing wear resistance, etc., can solve the problems of unable to provide realistic test conditions, inaccurate friction test data, affecting the friction mechanism of friction pairs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

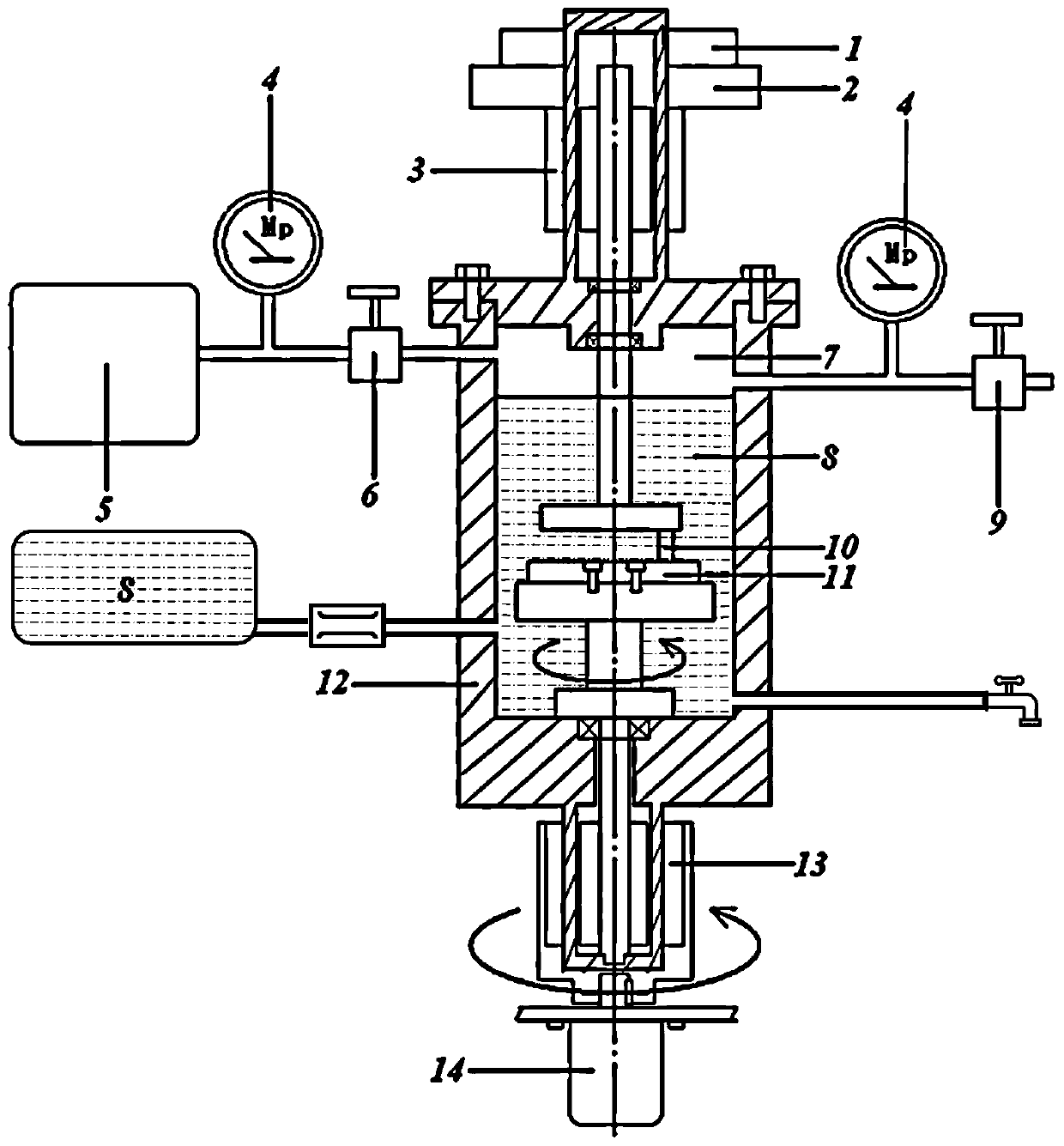

[0033] Example: such as figure 1 As shown, the friction and wear test device under high-pressure seawater environment includes: loading system, pressure system, and drive system;

[0034] The loading system includes: loading component 1, loading platform 2, magnet magnetic loader 3, fixed pin 10;

[0035] The pressure system includes: pressure gauge 4, nitrogen tank 5, intake valve 6, pressure relief valve 9, autoclave 12;

[0036] The driving system includes: a rotating disk 11, a magnet magnetic drive 13, and a motor 14;

[0037] The magnet magnetic loader 3 includes: an electromagnet ring, a magnet bar, and a loading shaft;

[0038] The magnet magnetic drive 13 includes: an annular magnet coupling, a rotating shaft, and a driving shaft;

[0039] The middle part of the autoclave 12 is a closed container with a large cylinder, a small cylinder at the center of the upper end and a small cylinder at the center of the lower end. The large cylinder is a high-pressure sea water cylinder, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com