Method for evaluating quality of high-density water-based drilling fluid mud cake

A water-based drilling fluid and evaluation method technology, applied in the direction of measuring devices, instruments, and mechanical devices, can solve the problems of no measurement standards, few desirable parameters, and unclear measurement indicators, and achieve good guiding significance and operability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

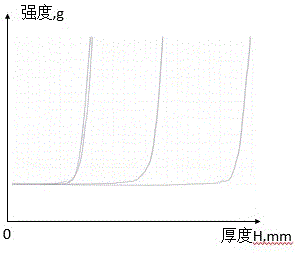

Image

Examples

example 1

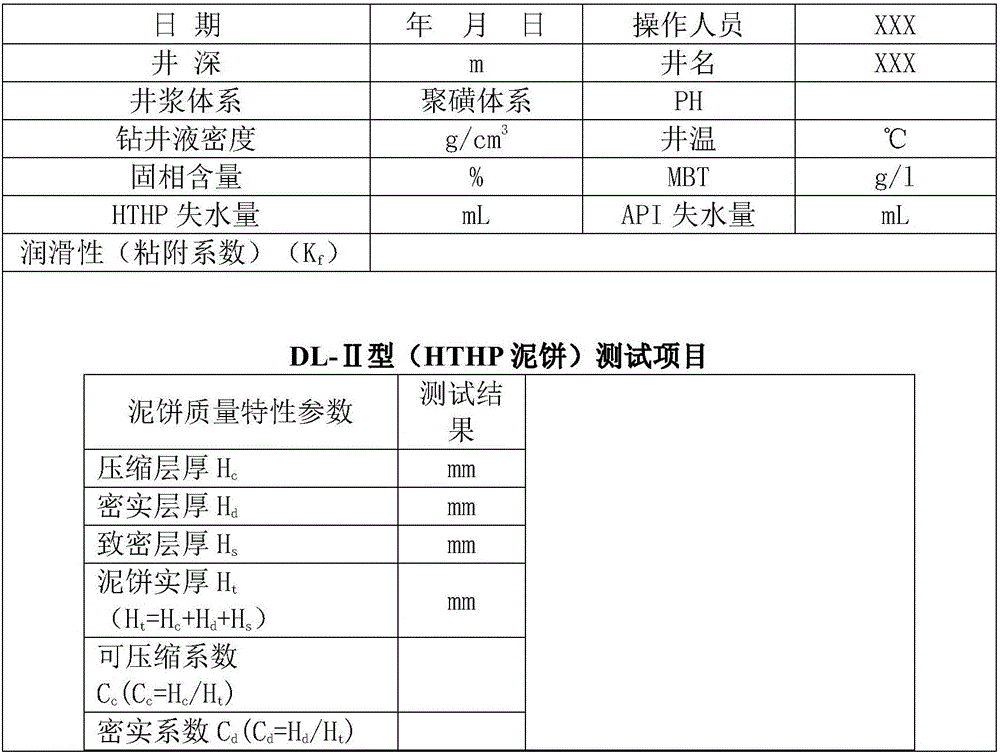

[0020] Example 1: Quality evaluation of high-density water-based drilling fluid mud cake in Well Dabei 302

[0021] 1. Quality evaluation steps of high-density water-based drilling fluid mud cake in Well Dabei 302:

[0022] (1) Take a certain amount of Dabei 302 well high-density water-based drilling fluid used in the field, pour it into the GGS42-2A AP high-temperature and high-pressure water loss tester, heat the high-temperature and high-pressure water loss tester to 150°C, and set the temperature at 3.5 Under the pressure of MPa, the mud cake formed by the high-density water-based drilling fluid system of Well Dabei 302 was prepared after 30 minutes;

[0023] (2) Pour out the residual drilling fluid system in the high-temperature autoclave body, take out the drilling fluid mud cake formed by the high-density water-based drilling fluid of Well Dabei 302 in the API high-temperature and high-pressure water loss instrument, and place it in the DL-Ⅱ mud In the cake tester, dra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com