Method for testing water content of foamed asphalt

A technology of foamed asphalt and testing methods, which is applied in measuring devices, analyzing materials, and using nuclear magnetic resonance to analyze, etc., can solve the problems of easy loss of tiny signals, inability to reflect micro-water droplets smaller than 10 microns, and limitation of CT imaging accuracy, etc., to achieve Achieve non-destructive testing, fast testing speed, and easy process control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

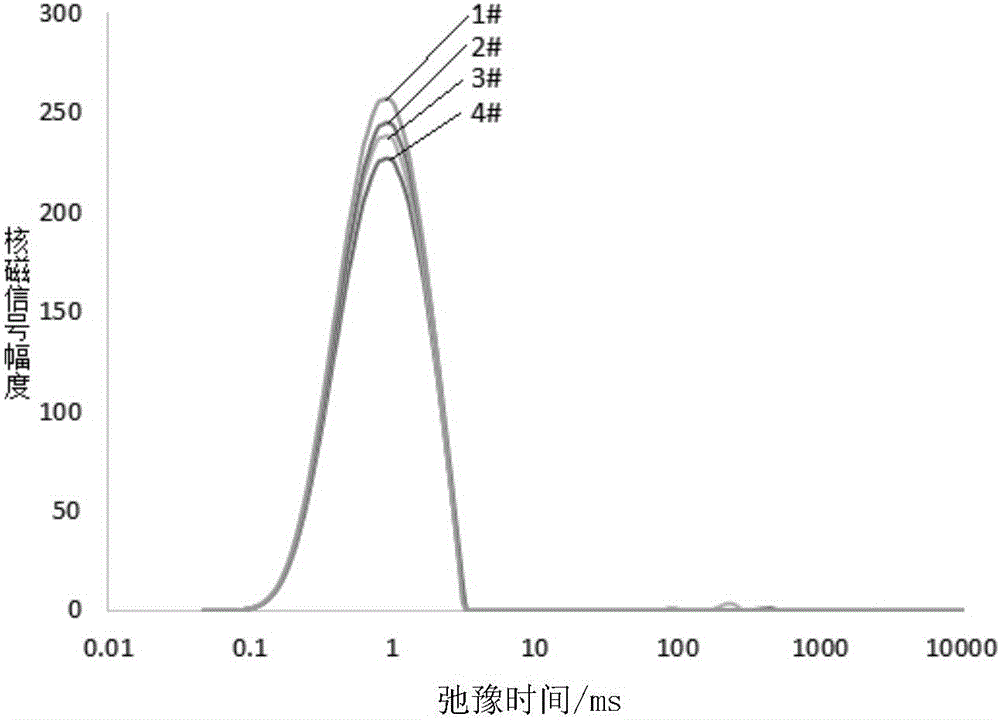

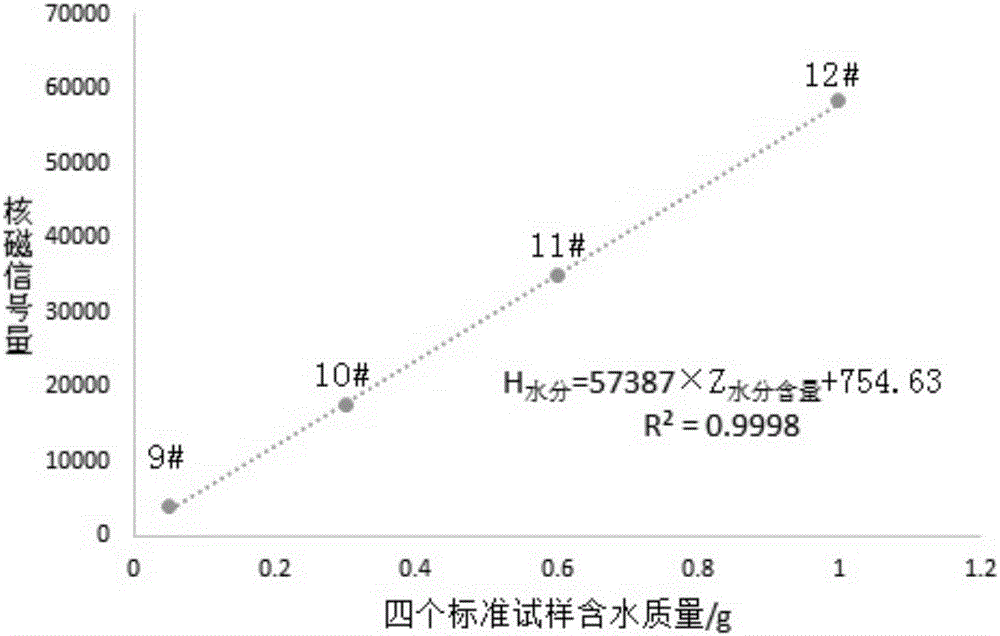

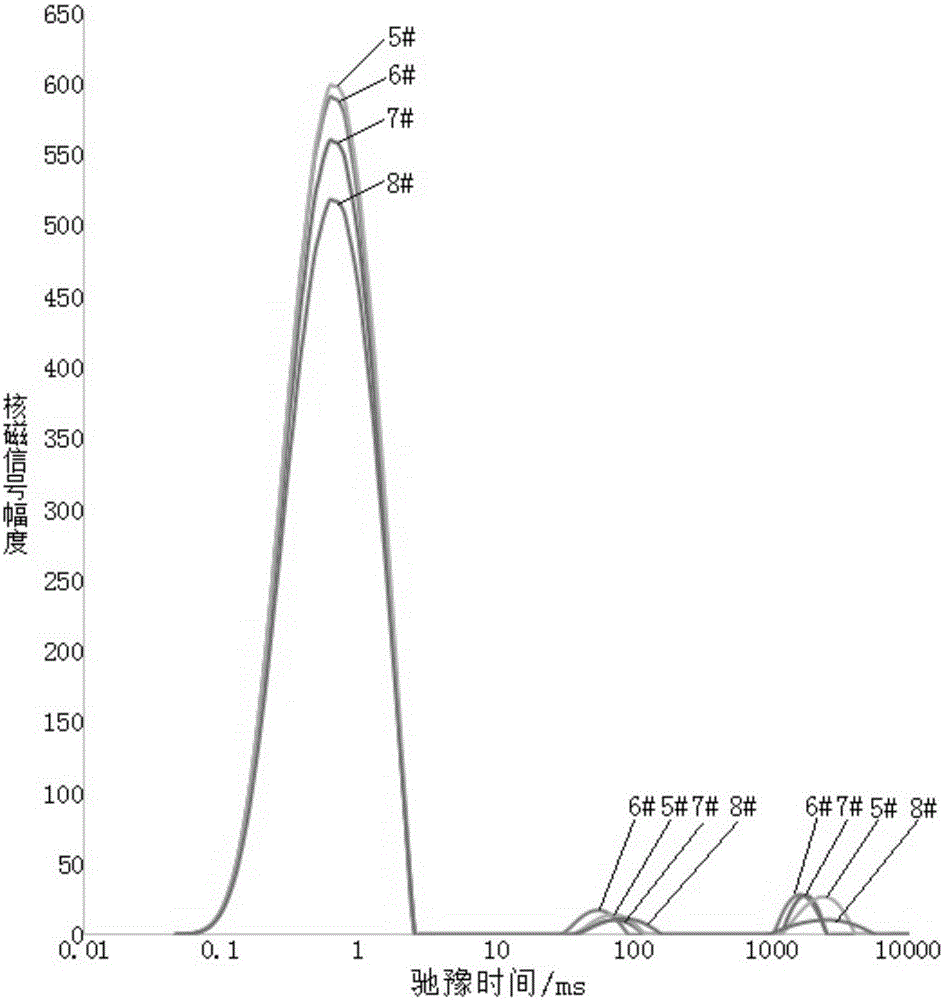

[0052] A kind of method for testing the moisture content of foamed asphalt of the present embodiment, the steps are as follows:

[0053] The first step, the preparation of the foamed asphalt sample to be tested for moisture content:

[0054] After heating the unfoamed base asphalt to a temperature of 150°C, start the indoor laboratory asphalt foaming device to spray it into foamed asphalt, collect the foamed asphalt in a 1000mL large glass beaker, and stir at a speed of 10 revolutions per minute for 120s. After standing still for 120s, inject 10 grams ± 1 gram of foamed asphalt into a glass bottle with a diameter of 20 mm, and then accurately measure the mass of the foamed asphalt sample injected into the glass bottle as Z 泡沫沥青试样 , and the accuracy requirement reaches 0.001 g. Put the glass bottle of the foamed asphalt sample to be tested for moisture content in a refrigerator at 2°C to 6°C for storage, and prepare four foamed asphalt samples for the moisture content to be tes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resonant frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com