Touch panel and manufacturing method thereof

A touch panel and manufacturing method technology, applied in the direction of instruments, electrical digital data processing, data processing input/output process, etc., can solve problems such as black matrix printing step difference, bubble defects, etc., to avoid height step difference, increase production capacity, Improve the effect of touch performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

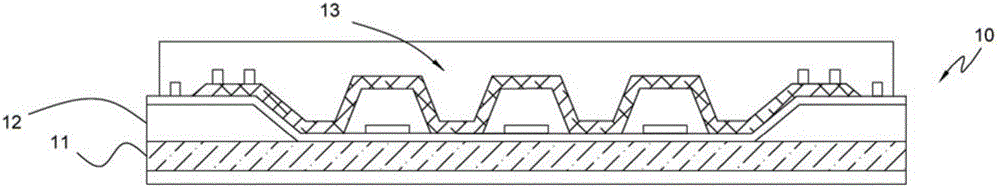

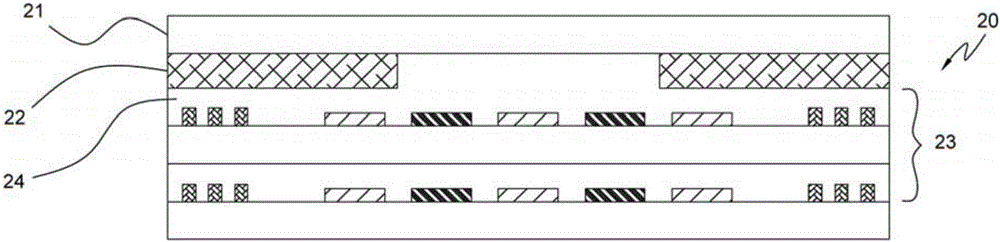

[0049] The invention discloses a touch panel and a manufacturing method thereof. The touch panel is applied to display devices, tablet computers, smart phones, notebook computers, desktop computers, televisions, satellite navigation, car displays, and aviation displays. or portable DVD players and other electronic devices, and touch screens can be divided into resistive touch screens and capacitive touch screens, of which capacitive touch panels mainly include film-type (Film-type ) and glass-type (Glass-type) touch panels, and the present invention mainly focuses on film-type touch panels, more particularly the structure of double-layer film-type (Glass-Flim-Flim, GFF) touch panels.

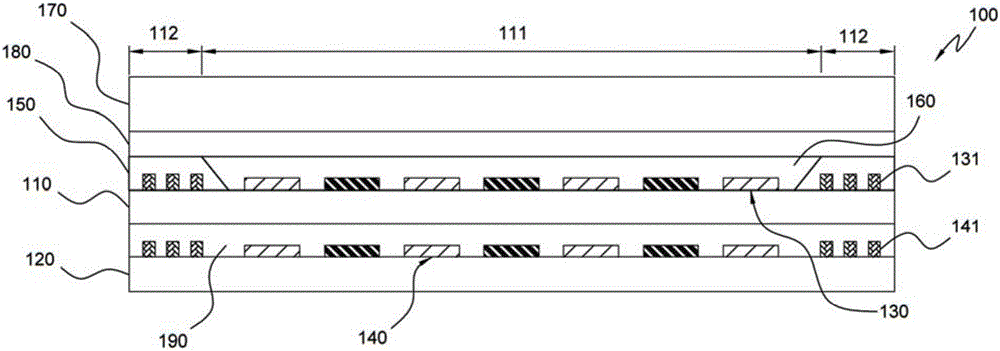

[0050] Please refer to image 3, is a cross-sectional structure diagram of the touch panel 100 provided by the embodiment of the present invention.

[0051] The touch panel 100 has a first substrate 110 and a second substrate 120 . Wherein, a sensing area 111 and a frame area 112 surrounding t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com