Prediction method for discrete pre-tightening force of bolt rotation angle method

A prediction method and technology of pre-tightening force, applied to threaded fasteners, screws, instruments, etc., can solve problems such as unpredictability, discrete pre-tightening force, and inability to obtain bolt tightening process, etc., to achieve clear and simple calculation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

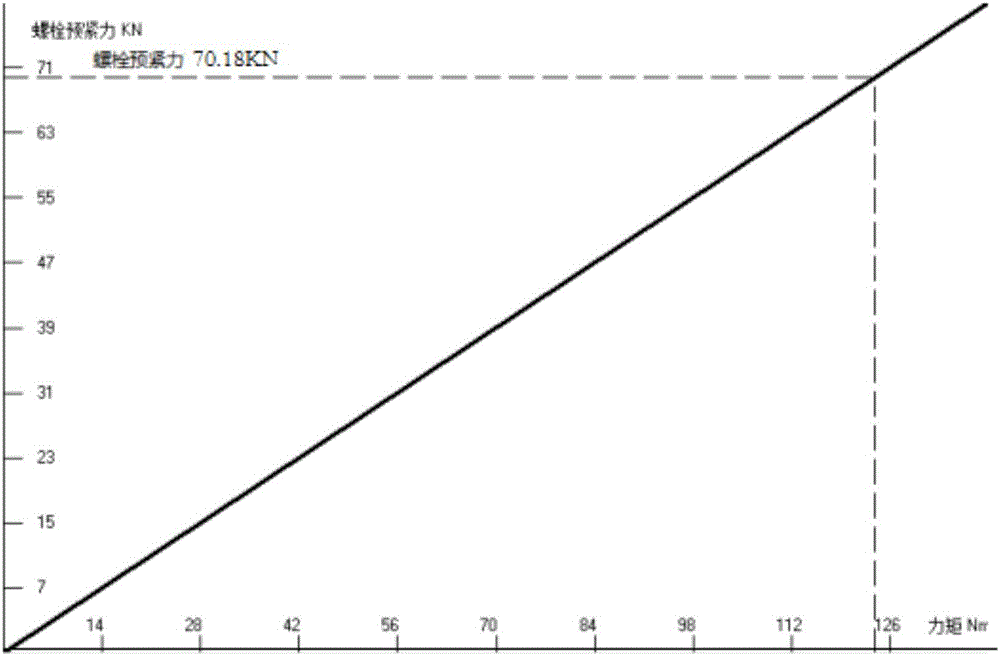

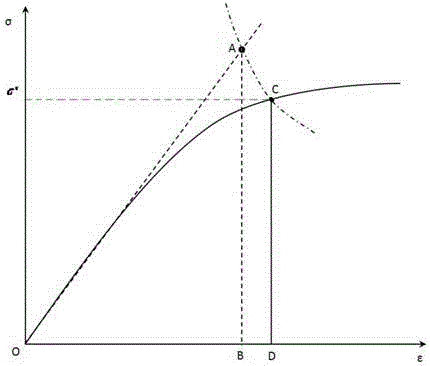

[0011] The calculation process of this method is described in detail below in conjunction with the accompanying drawings:

[0012] A method for predicting the discrete pretightening force of the bolt rotation angle method, which is to use the generalized Hooke's law to balance the force of the bolt connection pair in the elastic range, so as to obtain the pretightening force distribution of the rotation angle method; the elastic range is It refers to the fact that the deformation of the bolted joint pair under stress can return to its original size after unloading.

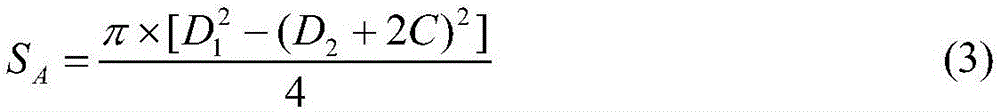

[0013] The parameters needed to calculate the bolt pretightening force are as follows: friction coefficient μ; yield strength σ s ;Torque T; Angle θ; Elastic modulus of bolt E bolt ;Elastic modulus of part A A ;Elastic modulus of part B B ;Outer diameter of bolt flange bearing surface D 1 ; Bolt polished rod diameter D 3 ;Chamfer C; Bolt hole diameter D 2 ; Bolt nominal diameter D bolt ; Bolt pitch P; Part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com