Keyboard and keyboard manufacturing method

A manufacturing method and keyboard technology, which can be applied to electrical components, electrical switches, circuits, etc., can solve the problems of high assembly defect rate, affecting the keyboard manufacturing yield, and damage to the internal components of the keyboard.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

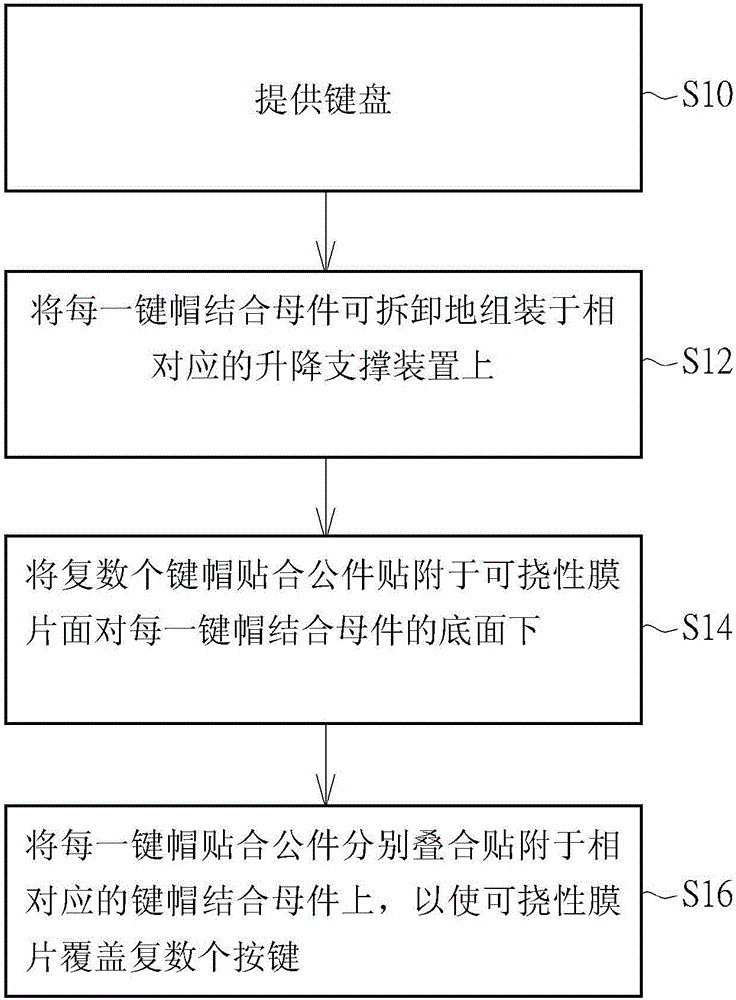

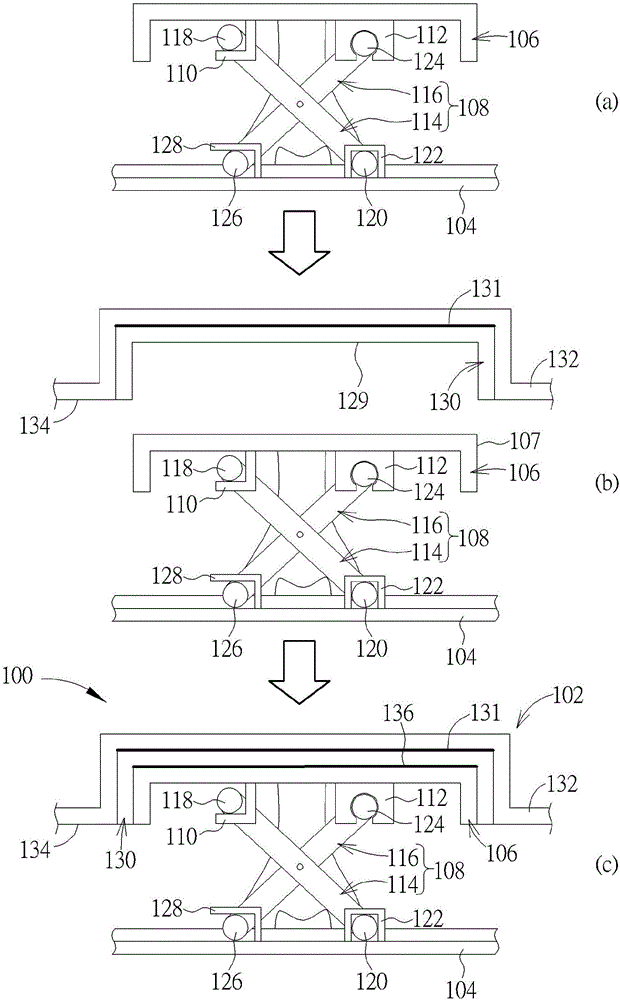

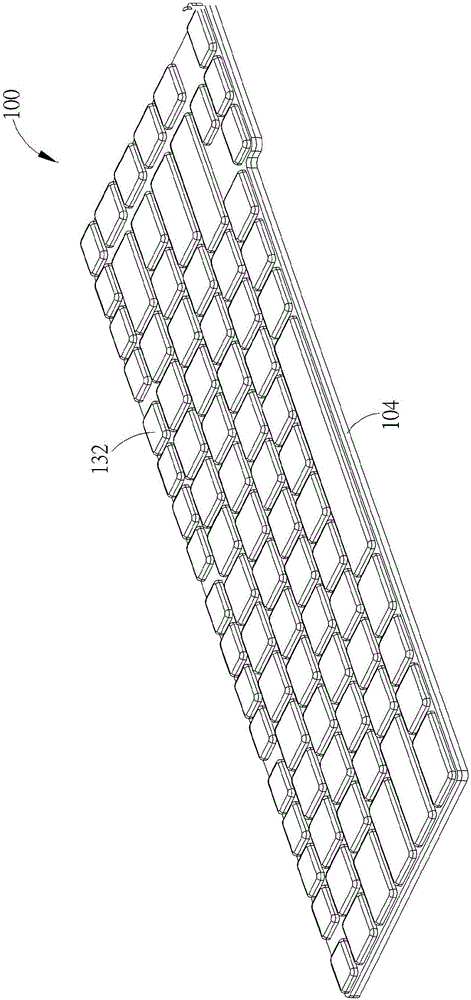

[0027] see figure 1 as well as figure 2 , figure 1 It is a flowchart of a keyboard manufacturing method proposed according to an embodiment of the present invention, figure 2 for matching figure 1 Schematic diagram of the process. First, step S10 is performed to provide a keyboard 100. The keyboard 100 may include a plurality of keys 102 and a bottom plate 104. Each key 102 may include a keycap coupling mother part 106 and a lifting support device 108. In order to clearly show the key structure design of the keyboard 100 ,exist figure 2 102 is only described for a single key 102 and presented in a cross-sectional view. As for the related descriptions for other keys, it can be deduced by referring to the following description, and will not be repeated here.

[0028] Next, execute step S12, such as figure 2 As shown in (a), each keycap coupling female part 106 is detachably assembled on the corresponding lifting support device 108, so that each keycap coupling female p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com