Method of re-fracturing using borated galactomannan gum

A technology of galactomannan and repeated fracturing, which is applied in the direction of chemical instruments and methods, earthwork drilling, drilling compositions, etc., and can solve problems such as insufficient production in production areas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

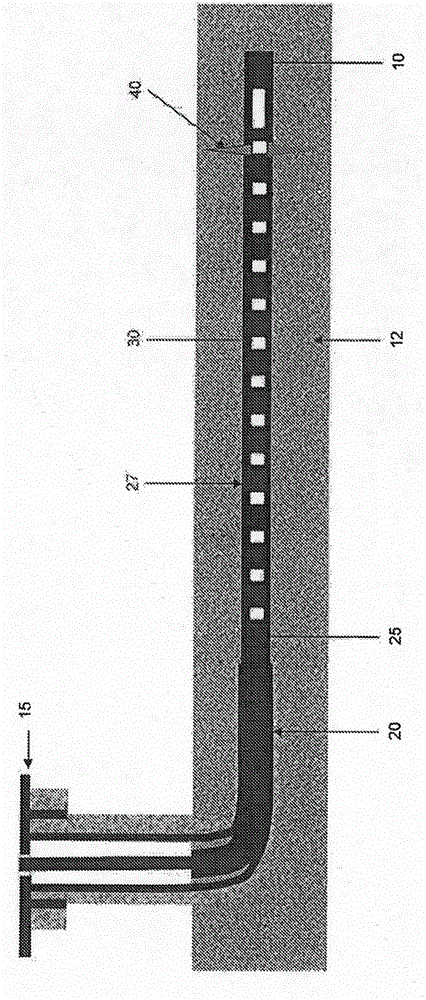

Image

Examples

Embodiment 1

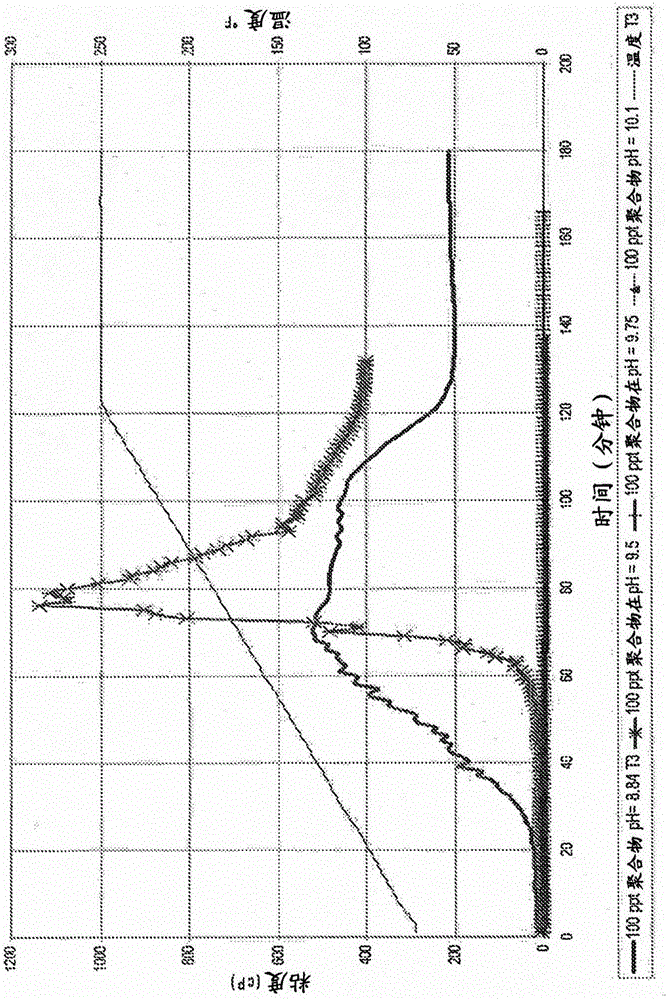

[0076] Example 1. The effect of different levels of pH on the onset of gel hydration was tested using viscosity measurements. The result is as figure 2 shown. In each test run, 100 ppt of polymer in water was used to generate a gel. The pH of the slurry was 8.84. Sodium hydroxide solution (10% by weight in water) was used to increase the pH to values of 9.5, 9.75 and 10.1. The slurry is loaded in the viscometer and measured at 100sec -1 The shear rate was used to determine the viscosity. The temperature of the viscometer was ramped from 70°F to 250°F over two hours and then held constant at 250°F for an additional hour. figure 2 shows that pH affects viscosity in the following way:

[0077] a. A pH greater than 9.75 causes the gel to not hydrate at all and become viscous;

[0078] b. At pH 9.5, the viscosity of the gel begins to increase after 60-65 minutes, but the viscosity is short-lived; and

[0079] c. At a pH of 8.84, the viscosity of the gel begins to increa...

Embodiment 2

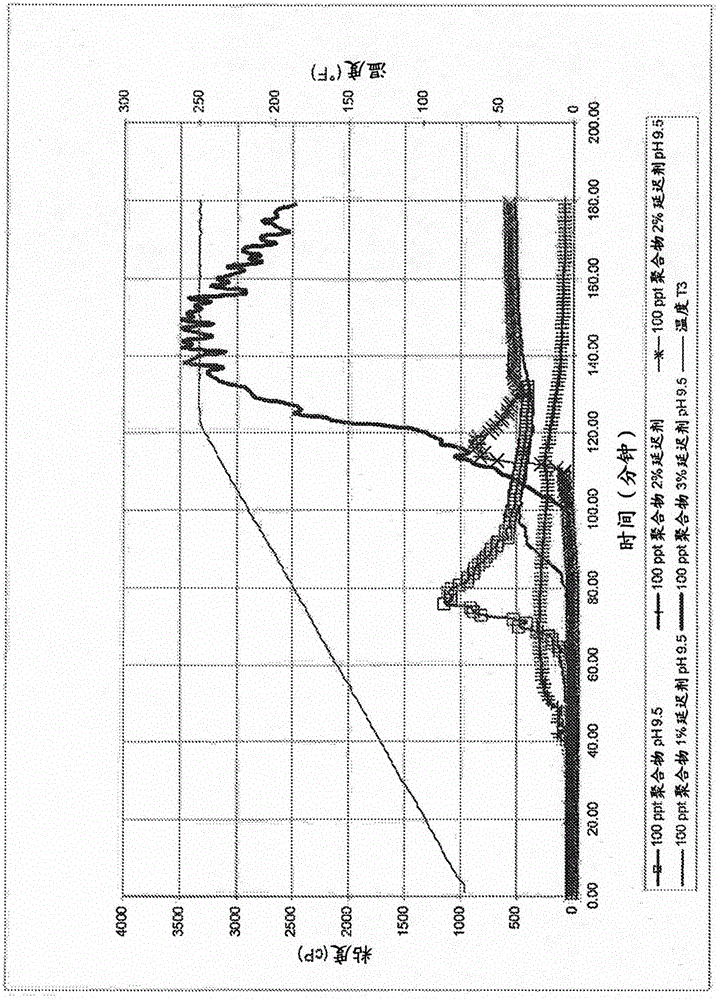

[0081] Example 2. Using the above procedure, the effect of adding borax as a retarder while maintaining a pH of 9.5 was examined. The result is as image 3 shown. For each run, 100 ppt of polymer in water was used and the pH was adjusted with sodium hydroxide solution to produce a gel. Borax was added as a retarder at 1%, 2%, 3% by weight of the polymer. The slurry is loaded in the viscometer and measured at 100sec -1 The shear rate was used to determine the viscosity. The temperature of the viscometer was ramped from 70°F to 250°F over two hours and then held constant at 250°F for an additional hour. The results indicated that borax by itself (without any pH adjustment) did not delay hydration, but made a significant difference in reducing the rate of hydration when the binding pH was increased from 8.84 to 9.5. specifically:

[0082] a. Control runs of the gel at native pH 8.84 and borax at 2% by weight of the polymer showed no difference in hydration;

[0083] b. ad...

Embodiment 3

[0087] Example 3. The influence of pH and retarder on hydration time was investigated and the results are as follows Figure 4 shown. For each test run, 100 ppt of polymer in water was used to generate the gel. The pH of the slurry was 8.84. Lower pH values were obtained by adding acetic acid until pH values of 8.5 and 8.75 were obtained. Higher pH values were obtained by adding sodium hydroxide solution (10% by weight in water), pH values 9 and 9.2. The slurry is loaded in the viscometer and measured at 100sec -1The shear rate was used to determine the viscosity. The temperature of the viscometer was ramped from 70°F to 100°F in 30 minutes and then held constant at 100°F for an additional 90 minutes. In some runs, borax was added as a retarder. The results show that hydration time can vary with pH. specifically:

[0088] a. Gels with a native pH of 8.84 and borax at 3% by weight of the polymer showed no difference in hydration;

[0089] b. Gels without retard...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com