Actuators with axially positioned and fixed components

A technology of actuators and components, which is applied in the field of actuators, can solve the problems of expensive interconnection, failure to achieve positioning accuracy, and unsatisfactory interconnection, etc., achieve effective structural space, achieve anti-torsion, and improve manufacturing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

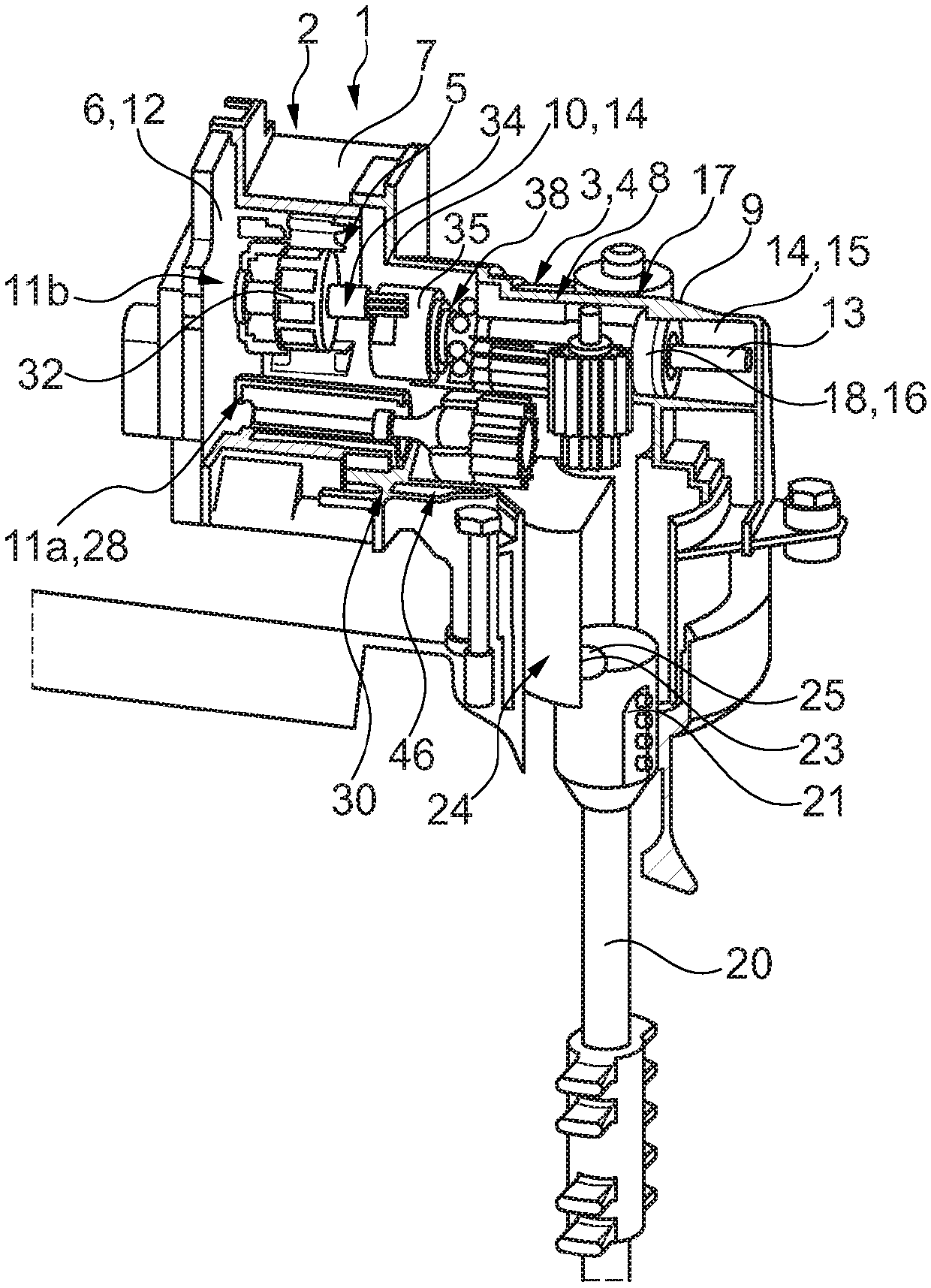

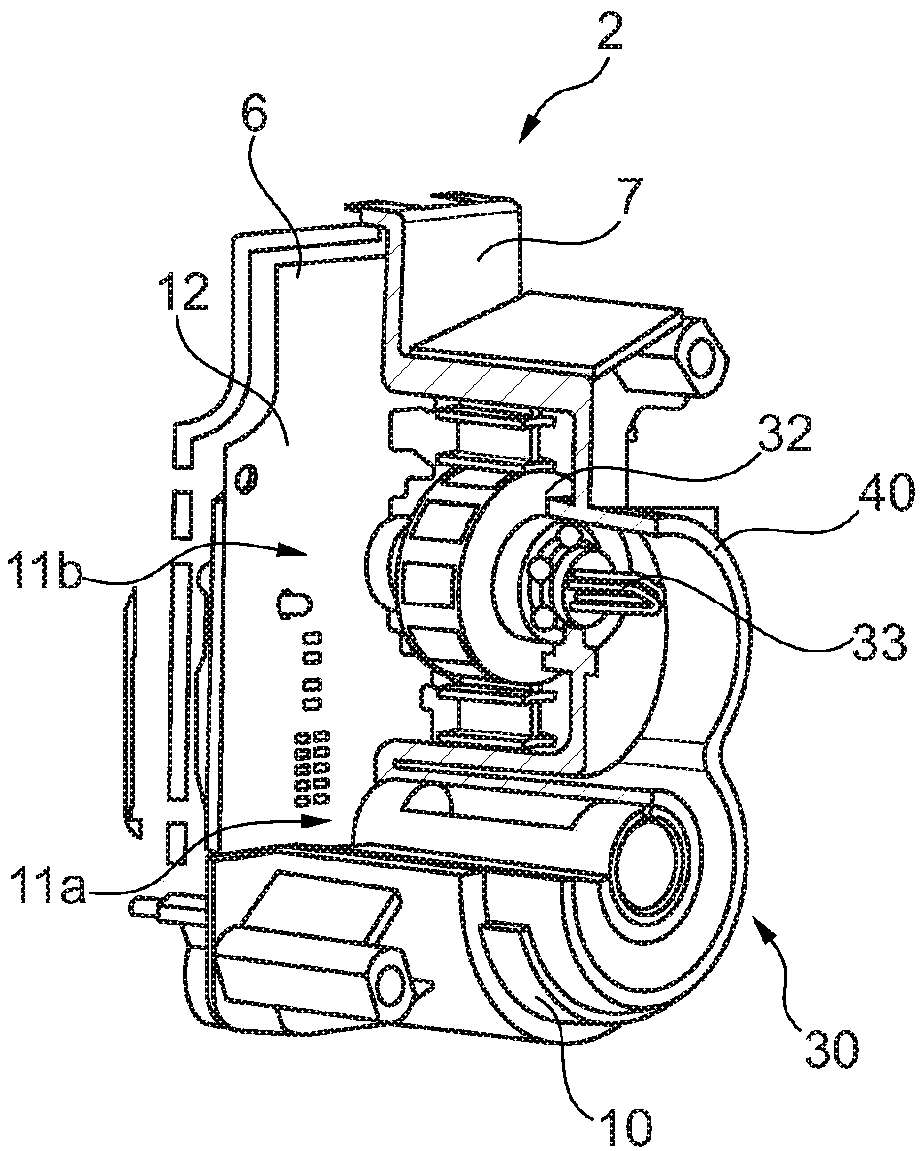

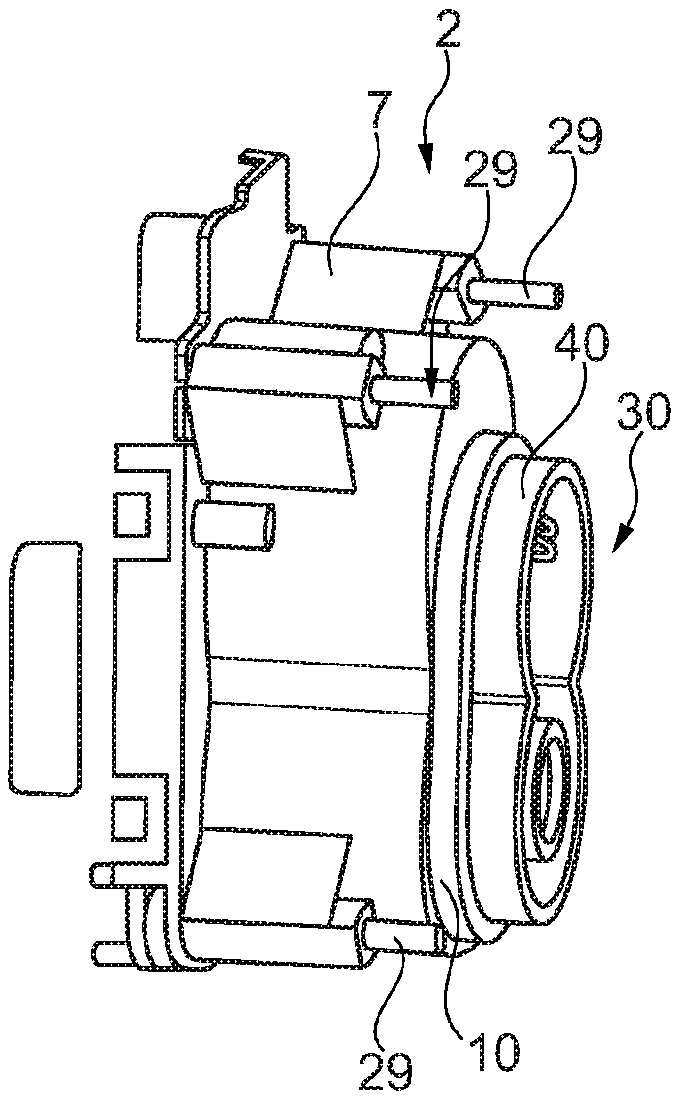

[0058] figure 1 The general structure of an actuator 1 according to the invention is shown according to a preferred (first) embodiment, which is designed as a single-motor transmission actuator. Its individual components are explained in detail in the following figures.

[0059] The single-motor transmission actuator 1 has a plurality of components and / or mechanisms and / or elements which are each individually protected subject matter individually and / or also in combination with each other. The same applies to the methods thus performed individually and / or in combination and also to the corresponding methods which, although capable of being carried out by means of the components, mechanisms and / or elements described, are carried out in the same manner as the The components, mechanisms and / or elements are independent and, accordingly, the method can be independently protected.

[0060] The single-motor transmission actuator 1 firstly has a drive unit 2 as an inspectable unit, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com