Membrane device for water purifier and encapsulation method of membrane device

A technology for water purifiers and membrane devices, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of large differences in the length of membrane filaments, increased cost of membrane filaments, and easy breakage of membrane filaments, etc., to achieve Reduce the chance of coalescing, increase the membrane filtration area, and prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

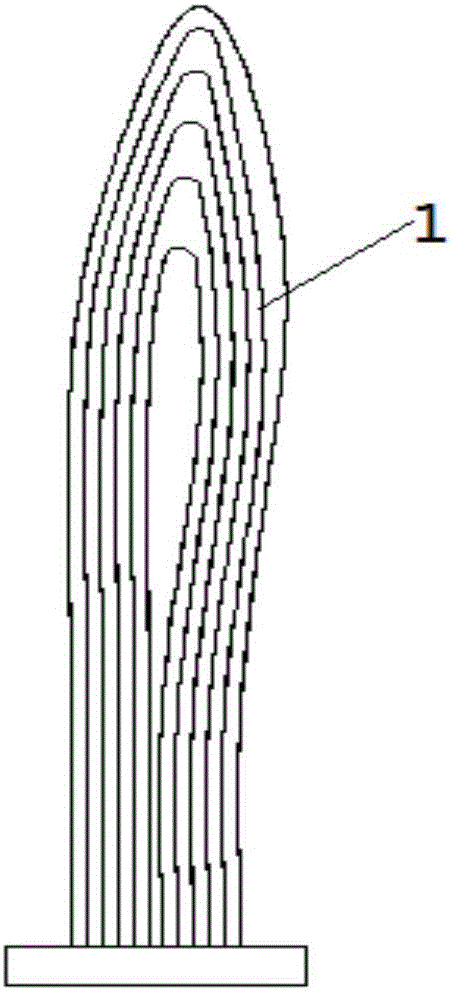

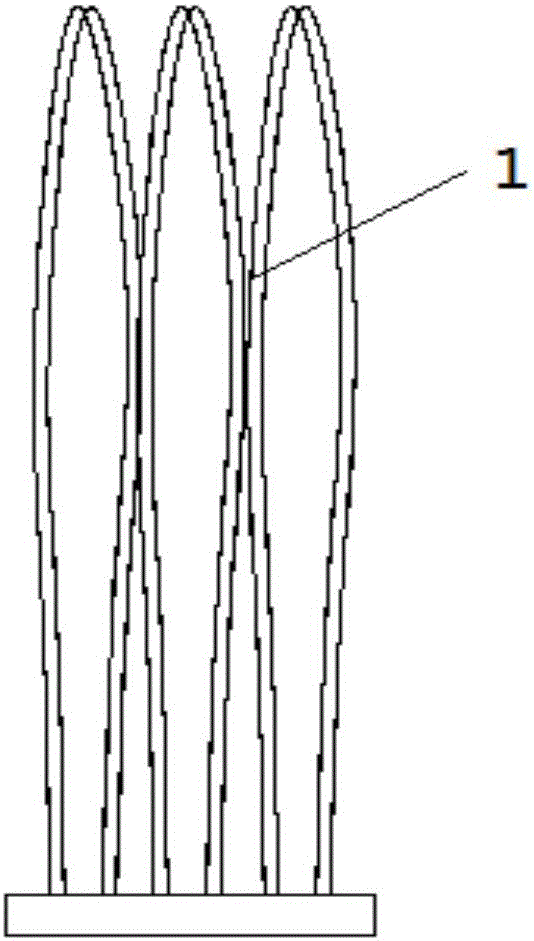

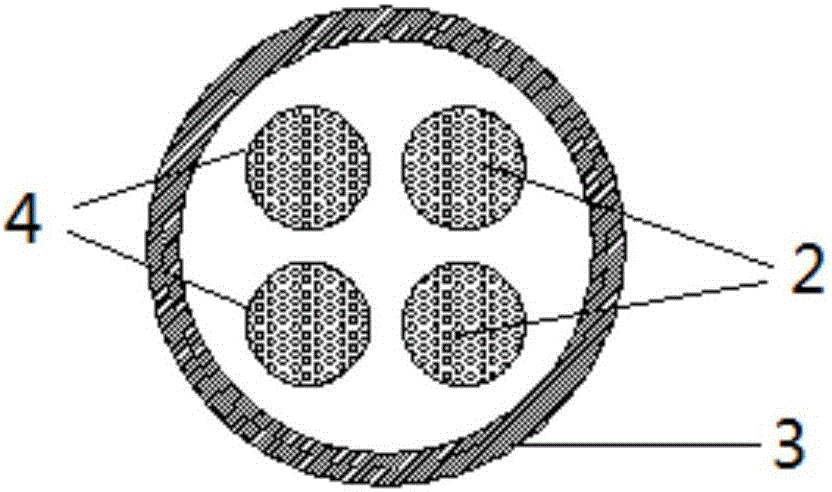

[0032] Every 50 polysulfone filter hollow fiber membrane filaments are divided into small bundles, and polyacrylonitrile-based activated carbon fibers such as Figure 4 The shown is evenly mixed into the filter hollow fiber membrane and cut into 150mm long; 1 equal-length exhaust hollow fiber membrane is added in the middle of 4 small bundles, and after U-shaped folding, it is wrapped with a separator net to form a middle membrane bundle. Such as Figure 3a As shown, the 4 middle membrane bundles are poured into the membrane shell with encapsulation glue to make the membrane device for water purifier. The size of the membrane shell is 36mm in diameter, 70mm in length, and the membrane area of the device is 0.15m 2 . The number of activated carbon fibers used is 3 / 50 of the number of filter hollow fiber membranes. The outer diameter of the filter hollow fiber membrane is 0.5mm, and the inner diameter is 0.35mm. The exhaust hollow fiber membrane is a hydrophobic membrane. 0....

Embodiment 2

[0034] Every 50 polysulfone filter hollow fiber membrane filaments are divided into small bundles, and polyacrylonitrile-based activated carbon fibers such as Figure 5 The shown spiral is wound on the outside of the filter hollow fiber membrane and cut into 150mm long; 1 exhaust hollow fiber membrane of equal length is added in the middle of the 4 small bundles and U-shaped folded and wrapped with a separator to form a membrane bundle, as shown in Figure 3a The four middle membrane bundles shown are poured into the membrane shell with encapsulation glue to make the membrane device for water purifier. The size of the membrane shell is 36mm in diameter, 70mm in length, and the membrane area of the device is 0.15m 2 . The number of activated carbon fibers used is 3 / 50 of the number of filter hollow fiber membranes. The outer diameter of the filter hollow fiber membrane is 0.5mm, and the inner diameter is 0.35mm. The exhaust hollow fiber membrane is a hydrophobic membrane. 0....

Embodiment 3

[0044] Every 25 filter hollow fiber membranes made of polyethersulfone are divided into small bundles, and polyacrylonitrile-based activated carbon fibers such as Figure 4Mix evenly as shown and cut into 250mm long, add 1 exhaust hollow fiber membrane filament of equal length in the middle of 8 small bundles, fold them in U shape and wrap them with separator net to form a middle membrane bundle. Such as Figure 3b As shown, 6 middle membrane bundles are poured in the membrane shell with encapsulation glue to make the membrane device for water purifier. The size of the membrane shell is 41mm in inner diameter, 100mm in length, and the membrane area of the device is 0.43m 2 . The number of activated carbon fibers used is 2 / 25 of the number of filter hollow fiber membranes. The outer diameter of the filter hollow fiber membrane is 0.6mm, and the inner diameter is 0.4mm. The exhaust hollow fiber membrane is a hydrophobic membrane. is 0.6mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com