Plastic curling and deforming machine

A deformation machine and crimping machine technology, which is applied in the field of chemical fiber processing, can solve the problems of gap expansion, plastic heat setting and elastic influence, and unstable curling effect of plastic film products, so as to achieve the effect of crimping and elastic stability, and improving crimping quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

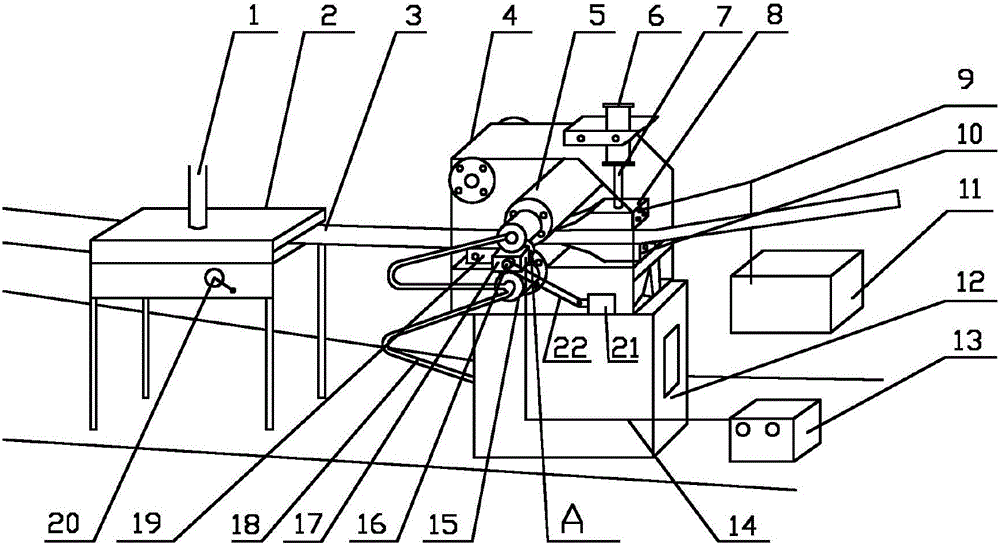

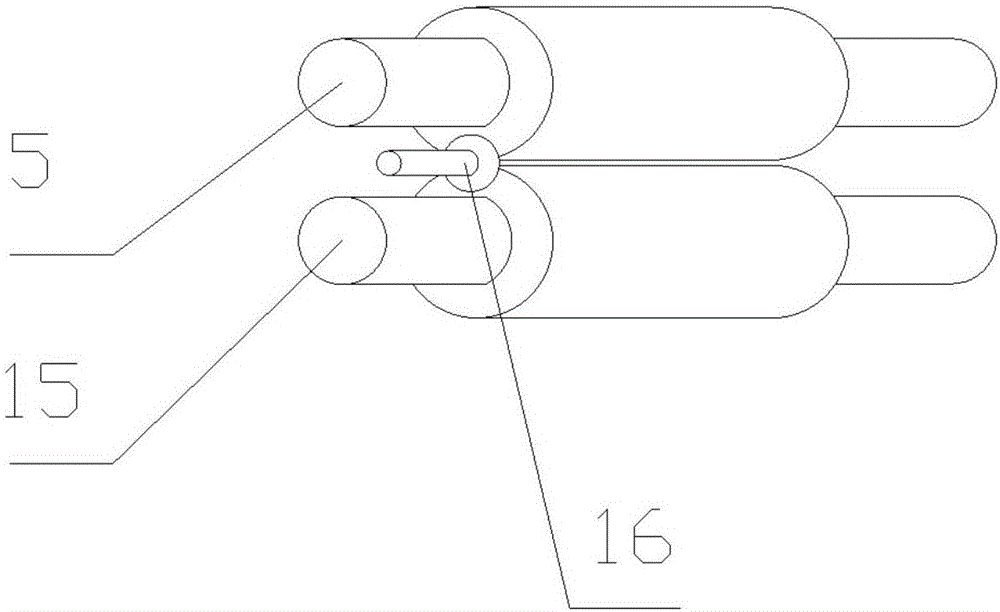

[0017] like figure 1 , figure 2 Shown, a kind of plastic crimping deformation machine comprises crimping frame 4, crimping frame 12, upper crimping wheel 5, lower crimping wheel 15, crimping frame 4 is fixed on the crimping frame 12, upper and lower crimping wheel 5, 15 is installed on the crimping frame 4 and is driven to rotate by the driving device. A rotating side plate mechanism 16 is arranged at the end face between the upper curling wheel 5 and the lower curling wheel 15, and the rotating side plate mechanism 16 is connected with the motor 21 through a transmission belt 22 , The rotating side plate mechanism 16 is made up of a shaft and a circular baffle, one end of the shaft is fixed on the circular baffle, and the other end is movably connected on the shell of the crimping frame 4. The superheated steam box 2 and the crimping machine base 12 are on the same center line, the steam pipe 1 is vertically installed on the superheated steam box 2, and the steam pipe (1) a...

Embodiment 2

[0019] A plastic crimping deformation machine, comprising a crimping frame 4, a crimping frame 12, an upper crimping wheel 5, and a lower crimping wheel 15, the crimping frame 4 is fixed on the crimping frame 12, and the upper and lower crimping wheels 5, 15 are installed on On the crimping frame 4 and driven to rotate by the driving device, a rotating side plate mechanism 16 is provided at the end face between the upper curling wheel 5 and the lower curling wheel 15, and the rotating side plate mechanism 16 is connected with the motor 21 through a transmission belt 22, and the rotating side The plate mechanism 16 is composed of a shaft and a circular baffle, one end of the shaft is fixed on the circular baffle, and the other end is movably connected to the shell of the crimping frame 4, and the rotating side plate mechanism 16 is also provided with a device for detecting rotation. The speed sensor 17 of the rotation speed of the side plate mechanism 16 is connected with the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com