Infinitely-variable-speed ultrasonic microdroplet jetting additive manufacturing device and method for multiple materials

A droplet ejection and additive manufacturing technology, applied in the field of additive manufacturing, can solve the problems of additive manufacturing, easy clogging of nozzles, and limitation of the size of ejected droplets, so as to reduce manufacturing costs and improve printing accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

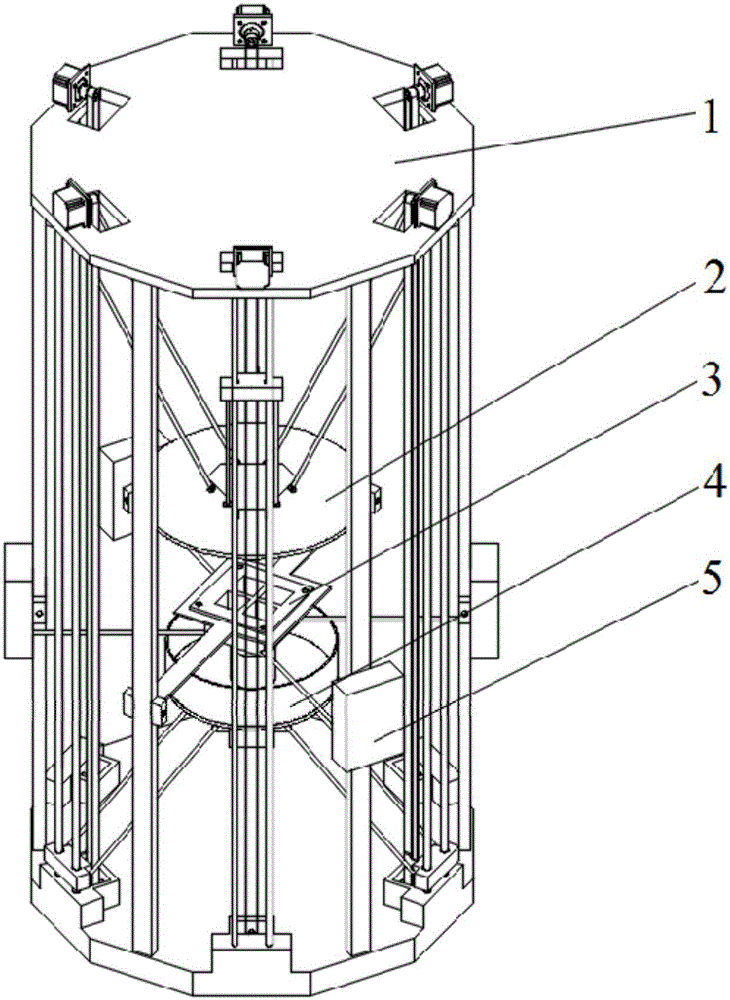

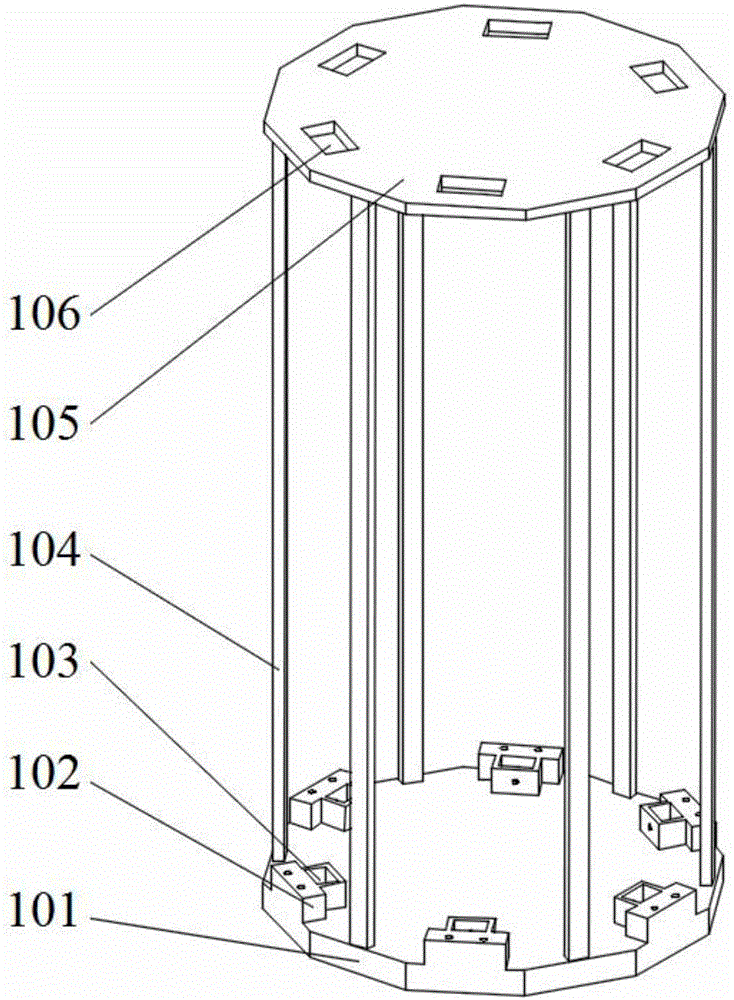

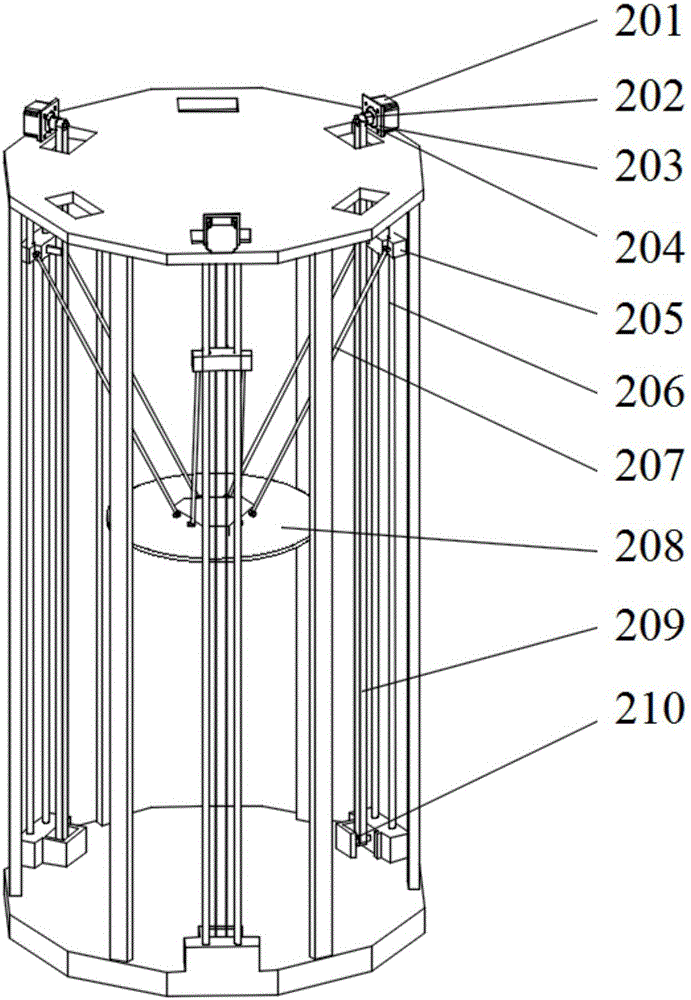

[0029] It includes a frame 1, a delta motion substrate device 2, a material pool device 3, a focused ultrasound system 4, and a feeding device 5. The delta motion substrate device 2 is fixed in the frame 1 and is located below its top plate 105. The described The focused ultrasound system 4 is fixed in the frame 1 and located above its bottom plate 101, the material pool device 3 is located above the focused ultrasound system 4 and fixed on the frame 1, and the described feeding device 5 is fixed on the frame 1 on the support column 104. The continuously variable speed multi-material mixed ultrasonic droplet injection additive manufacturing device combines focused ultrasonic technology and additive manufacturing technology to realize the continuously variable speed multi-material mixed ultrasonic droplet jet additive manufacturing, which can solve the problem of existing droplet The injection droplet size of the injection additive manufacturing system is limited by the nozzle,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com