Fastening System And Axle Subframe

A technology of auxiliary frame and fixing system, which is applied in the direction of vehicle components, transportation and packaging, and substructure, etc., which can solve the problems of impossible, expensive manufacture of fully quenched and tempered sleeves, and inability to connect the auxiliary frame of the shaft, so as to reduce the Abrasion, easy insertion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

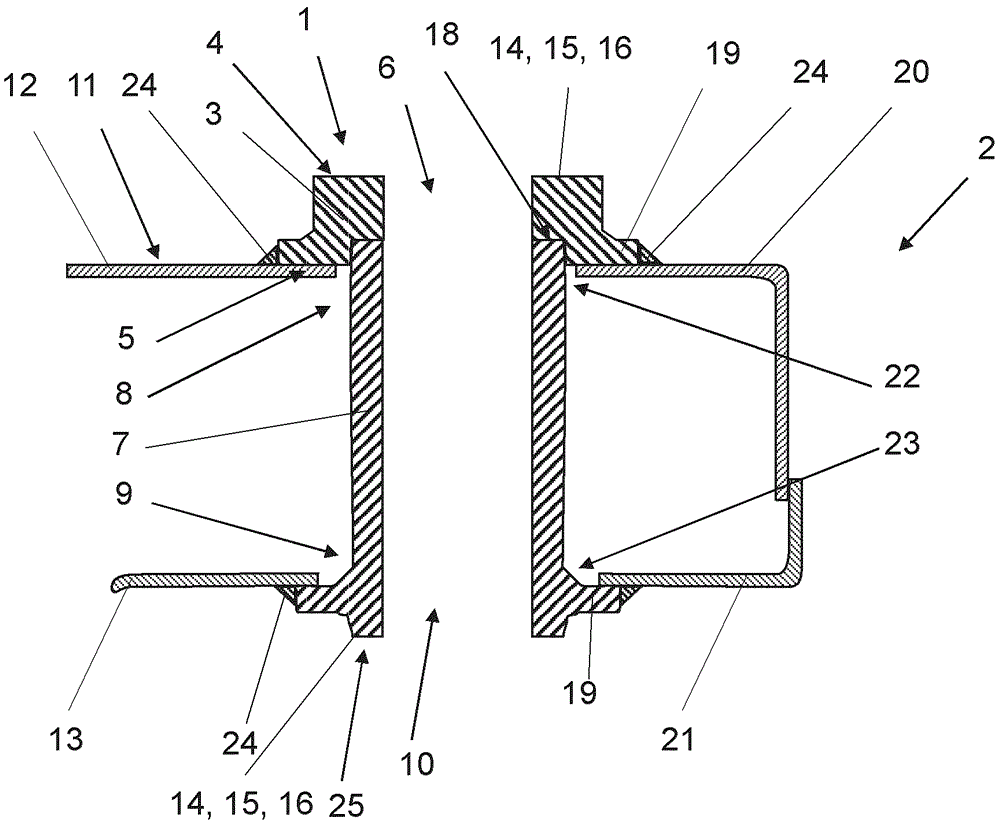

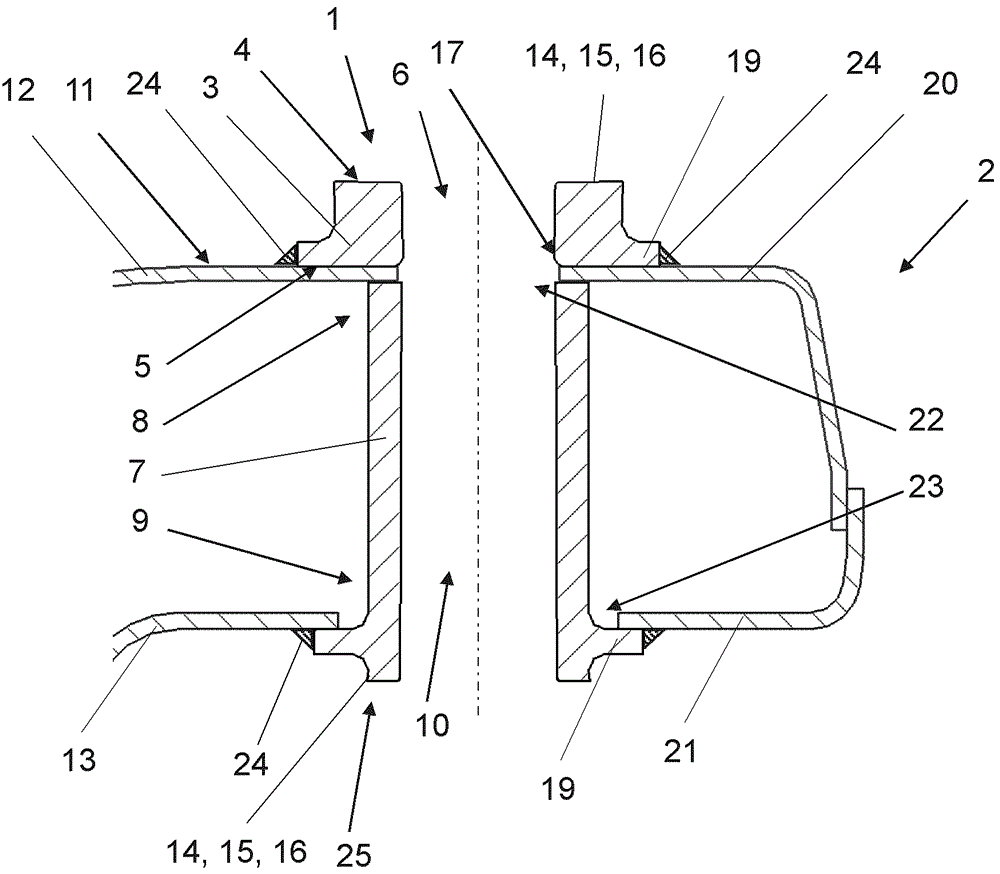

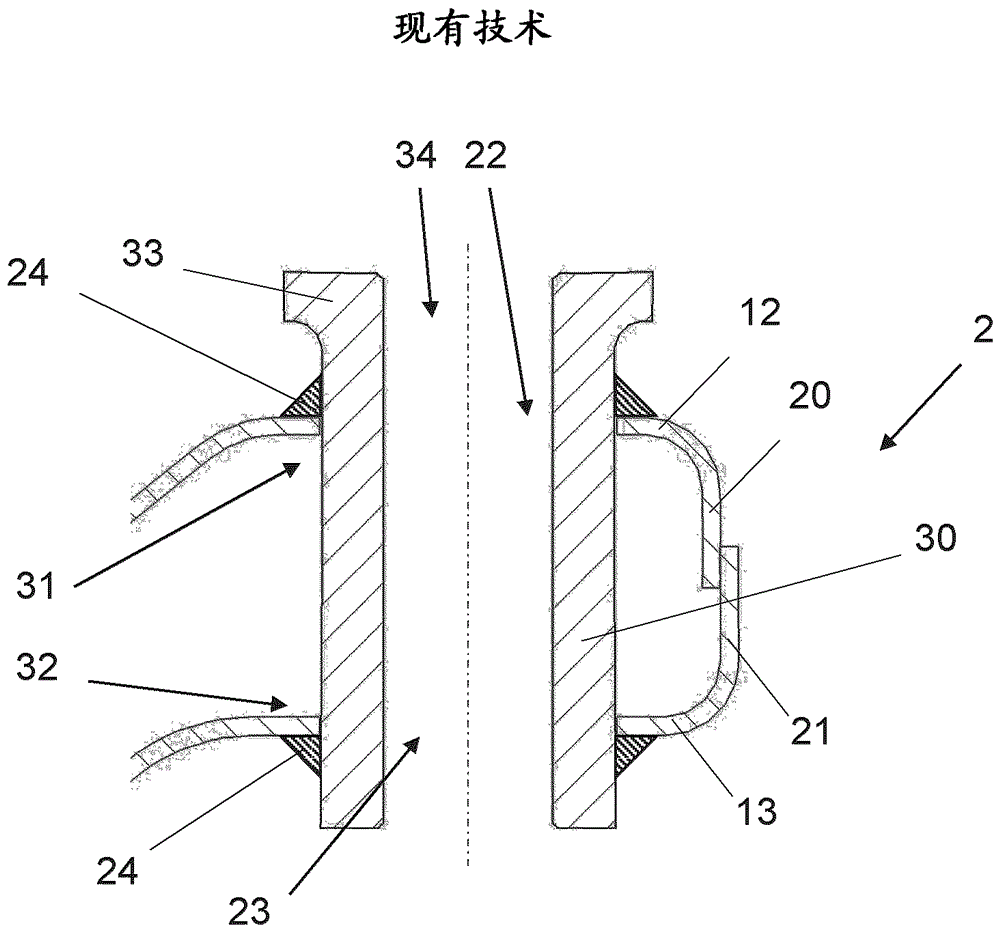

[0066] exist figure 1 The axle subframe 2 shown in section in , has a subframe upper part 20 with a first wall 12 and a subframe lower part 21 with a second wall 13 , which are connected to one another. The subframe upper part 20 has a first recess 22 which is arranged in alignment with a second recess 23 of the subframe lower part 21 . A subregion of the support sleeve 30 is introduced through the first recess 22 . The support sleeve 30 has a first support sleeve region 31 , a second support sleeve region 32 and a central support sleeve recess 34 extending in the longitudinal direction of the support sleeve 30 , which is designed for the insertion of the fastening means ( For example, part of a bolt shank or pin shank). The first support sleeve region 31 has a support ring 33 at one end of the support sleeve 30 , which is placed on the side of the first wall 12 facing away from the second wall 13 and is welded thereto by means of a weld seam 24 . One end of the second supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com