A method for repairing aircraft pressurized cockpit skin

A skin and cockpit technology, applied in aircraft maintenance, fuselage bulkheads, etc., can solve the problems of reducing the fatigue strength of rivet connections, impact, and the difficulty of regular inspection and maintenance work, so as to facilitate the detection of abnormal signs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

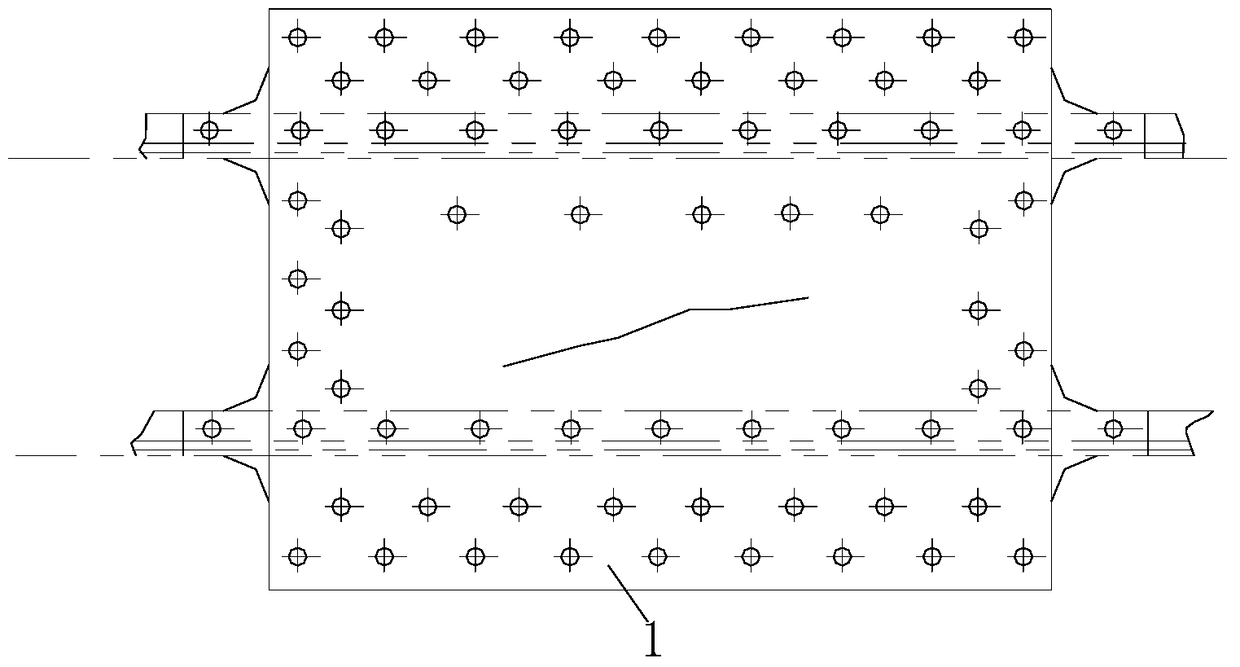

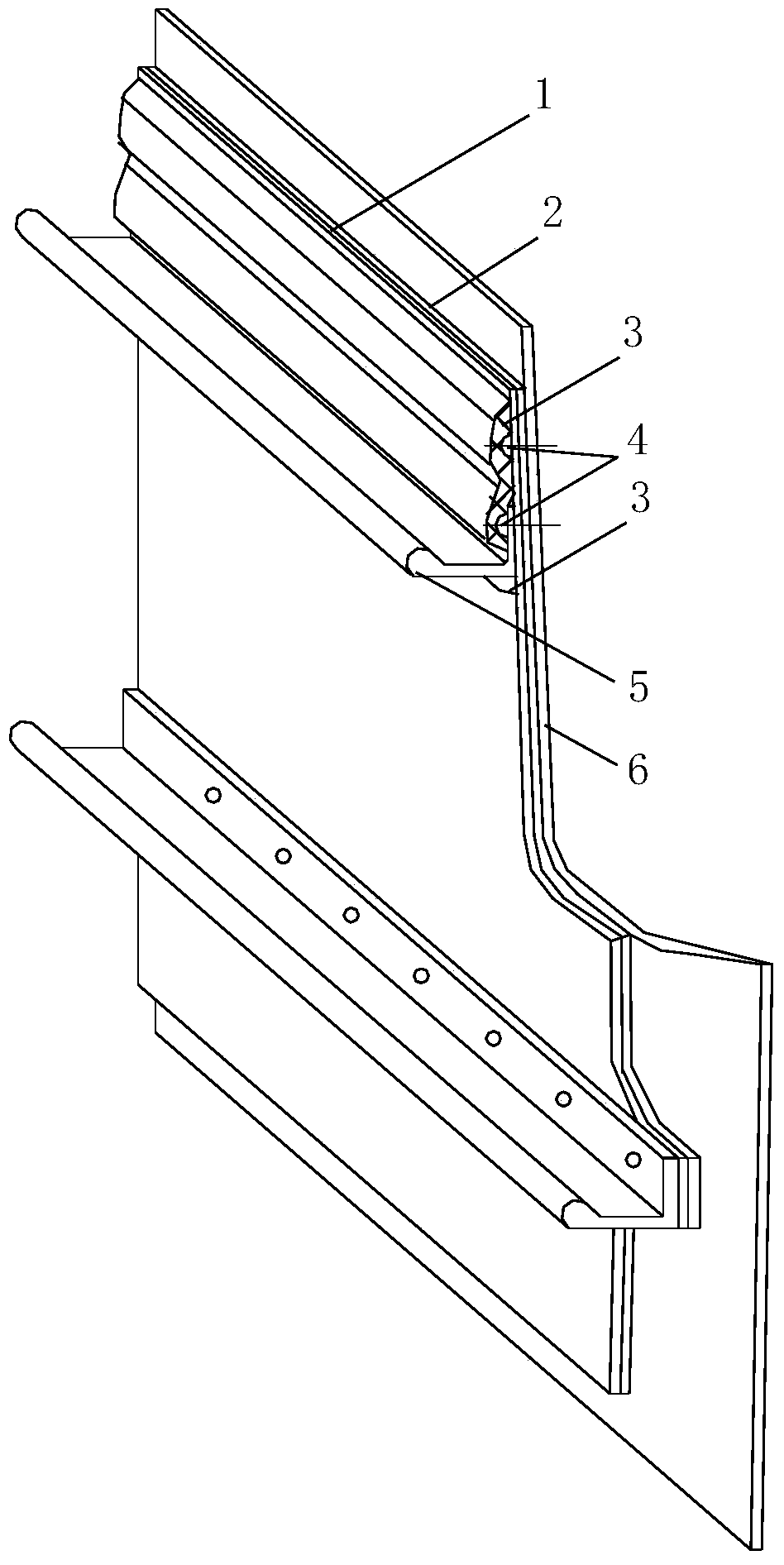

[0021] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment: a kind of specific form of aircraft pressurization cockpit skin repair method is as follows Figure 1 ~ Figure 3 shown. When repairing the pressurized cockpit skin of an aircraft in this method of use, first decompose the rivets 4 of the stringers 5 adjacent to the damaged skin 6, clean the inner surface of the damaged skin 6, lay the interlayer sealing material 2, and repair the damaged skin 6. A reinforcing backing plate 1 is placed on the inner surface of the skin, then riveted, and a sealant 3 is applied.

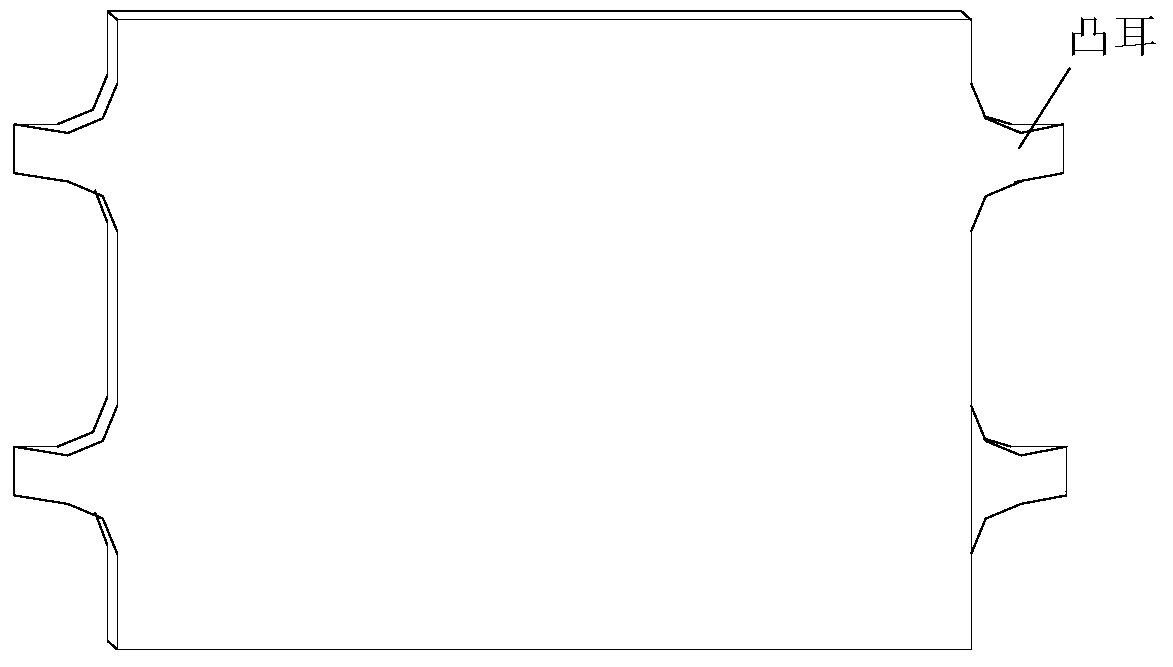

[0022] Reinforced backing plate is being made, according to figure 1 Make the reinforced backing plate 1 and set lugs, the grade of the reinforced backing plate material is LY12, heat treatment and yellow anodizing treatment after forming, and apply primer; Along the axial direction of the stringer 5, an extension section with the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com