A vacuum device and activated carbon packaging machine in the process of packaging powdered activated carbon

A vacuum device, powdered activated carbon technology, applied in the direction of packaging, transportation and packaging, special packaging items, etc., can solve the problem that the packaging efficiency and volume requirements cannot be met, the unit vacuum degassing volume cannot be designed too large, and the degassing volume cannot be adjusted and other problems, to achieve the effect of saving transportation costs, improving the working environment, and reducing the gas content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

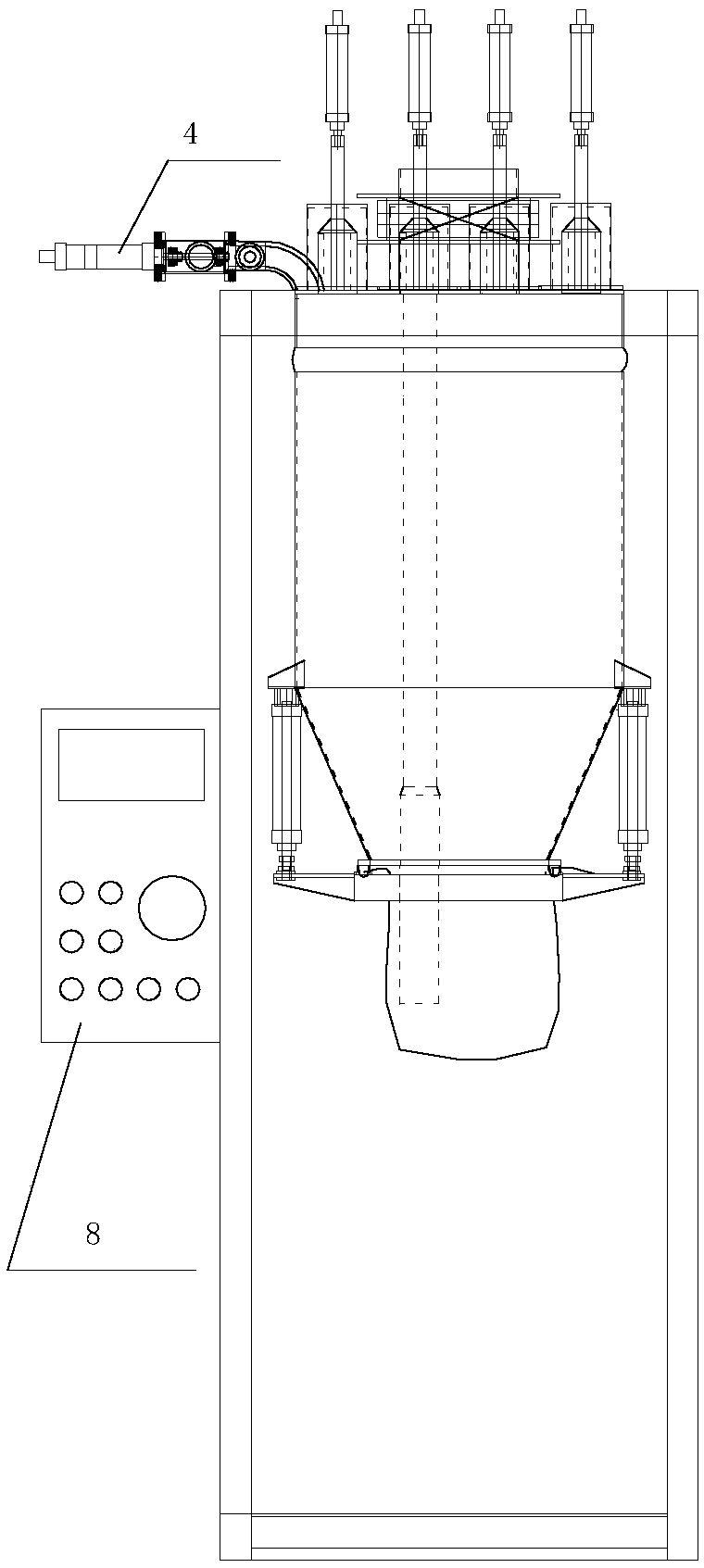

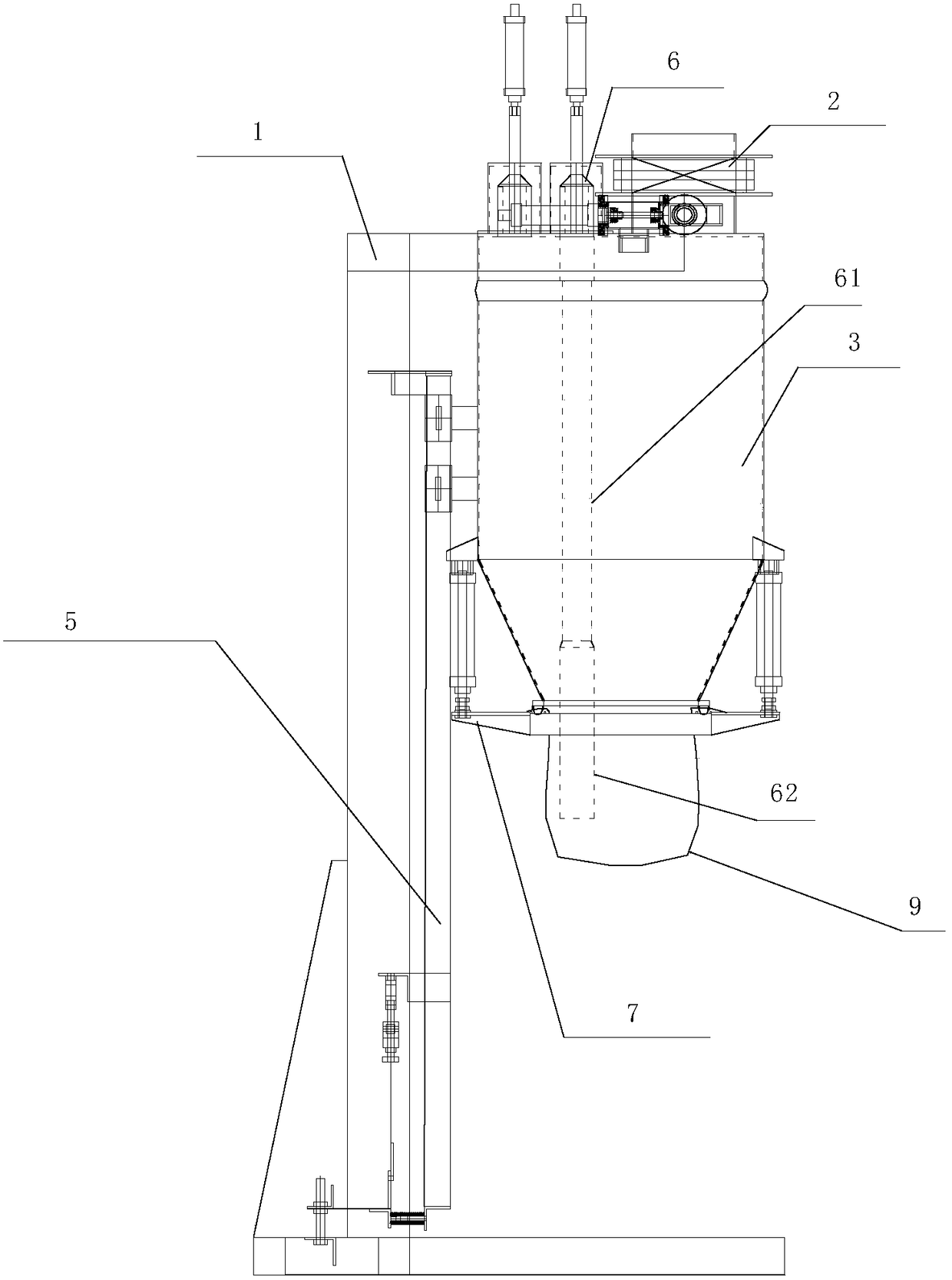

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

[0030] refer to figure 1 and figure 2 , a vacuumizing method in a powdery activated carbon packaging process, the vacuumizing method comprising:

[0031] During the packaging process of the activated carbon packaging machine, when the powdered activated carbon enters the silo 3 through the feeding mechanism 2, and the powdered activated carbon in the silo is weighed by the weighing device 5, the weighed powdered activated carbon enters the activated carbon In the packaging bag 9, the powdered activated carbon in the activated carbon packaging bag 9 is vacuumized by the vacuum device 6;

[0032] At first according to the kind and the weight of powdered activated carbon, the time of vacuumizing is set on control device 8;

[0033] Then, control the lifting mechanism through the control device 8 to drive the connecting pipe 61 to move downward, and at the same time, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com