Wrap angle posture adjusting mechanism and angle wrapping machine

A technology for adjusting the mechanism and wrapping angle, which is applied in the directions of packaging, transportation and packaging, and the type of packaged items. It can solve the problems that the wrapping angle is prone to skew, incorrect working position, and incorrect position, so as to avoid incorrect falling posture and pressing action. Flexible, anti-skew effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

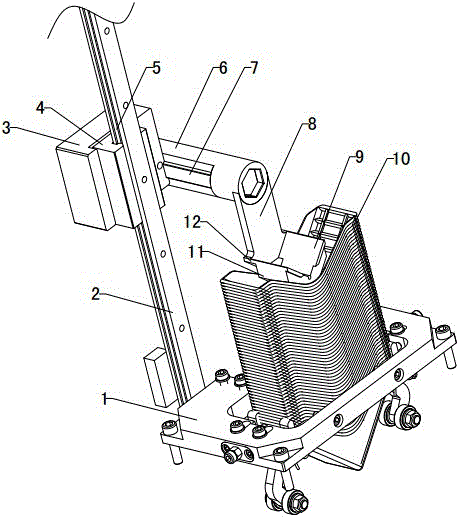

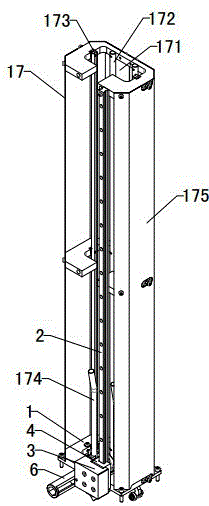

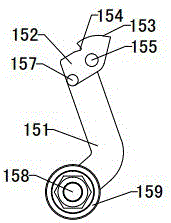

[0030] Figure 1~7 It is the best embodiment of the present invention, below in conjunction with attached Figure 1~7 The present invention will be further described.

[0031] Refer to attached Figure 1~3 : Angle-wrapping attitude adjustment mechanism, including a lower pressing mechanism, a slide rail 2 and a sliding lifting mechanism that can drive the lower pressing mechanism to lift up and down. The sliding lifting mechanism is slidably installed on the sliding rail 2, and one side of the sliding lifting mechanism is connected to the lower pressing mechanism. The lower end of the pressing mechanism is pressed on the top of a plurality of superimposed wrap angles 10 in the wrap angle storehouse, and the slide rail 2 is vertically fixed on the fixed disk 1 side of the bottom of the wrap angle storehouse, and the wrap angle 10 is placed on the fixed disk 1.

[0032] The pressing mechanism is a briquetting block 9 arranged in a V shape. The briquetting block 9 includes a pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com