Rotary disc type cargo classifying device

A sorting device and turntable technology, which is applied to rotary conveyors, conveyor control devices, sorting, etc., can solve the problems of low efficiency of manual sorting and picking of goods, inability to sort and pick in small spaces, waste of human resources, etc., and achieve Improve scanning efficiency and work efficiency, save manpower handling, and reduce the effect of the work site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

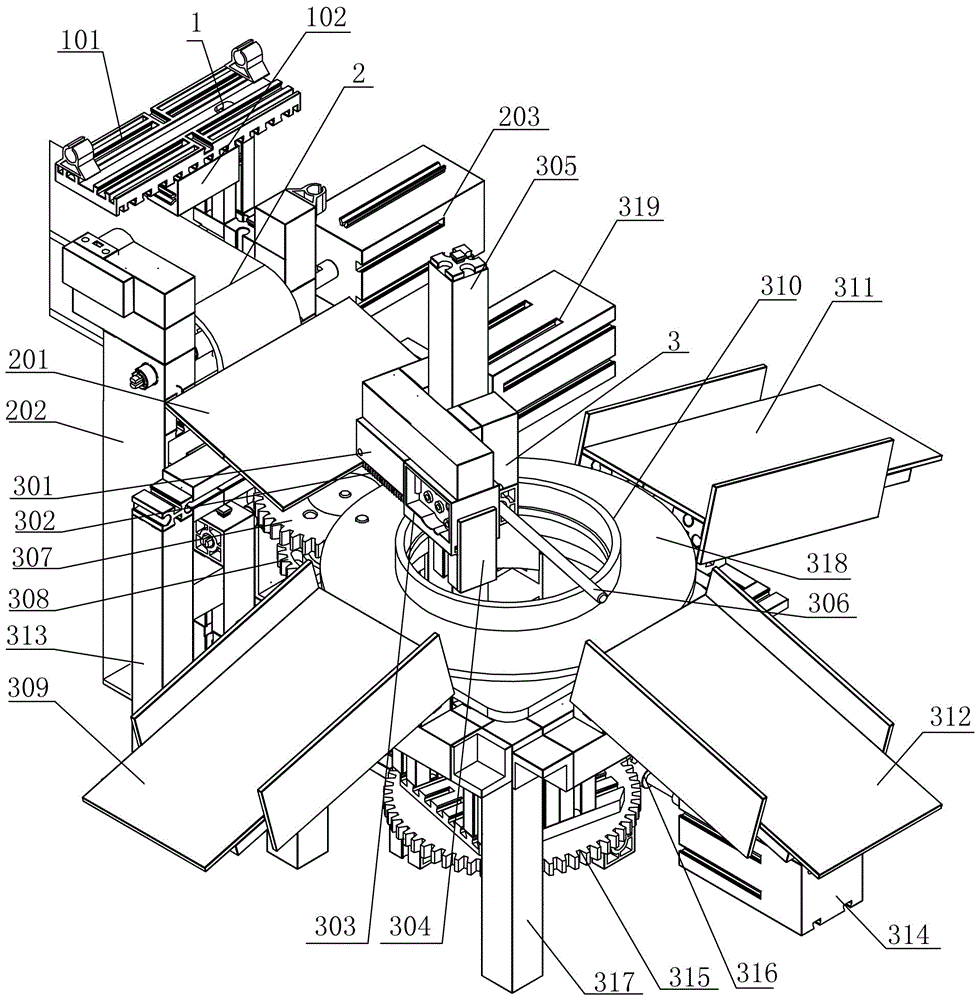

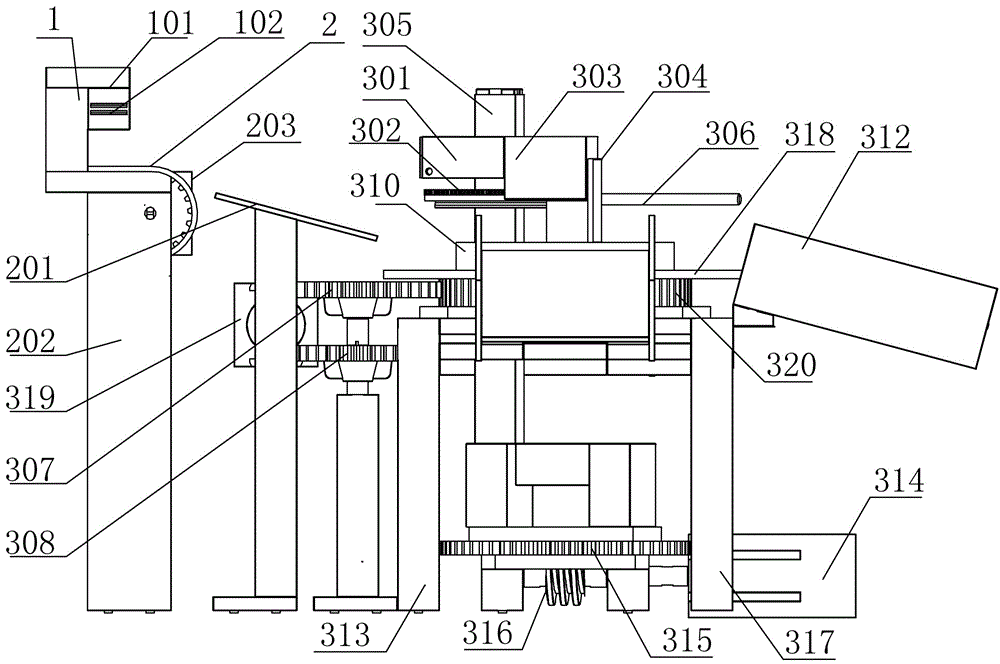

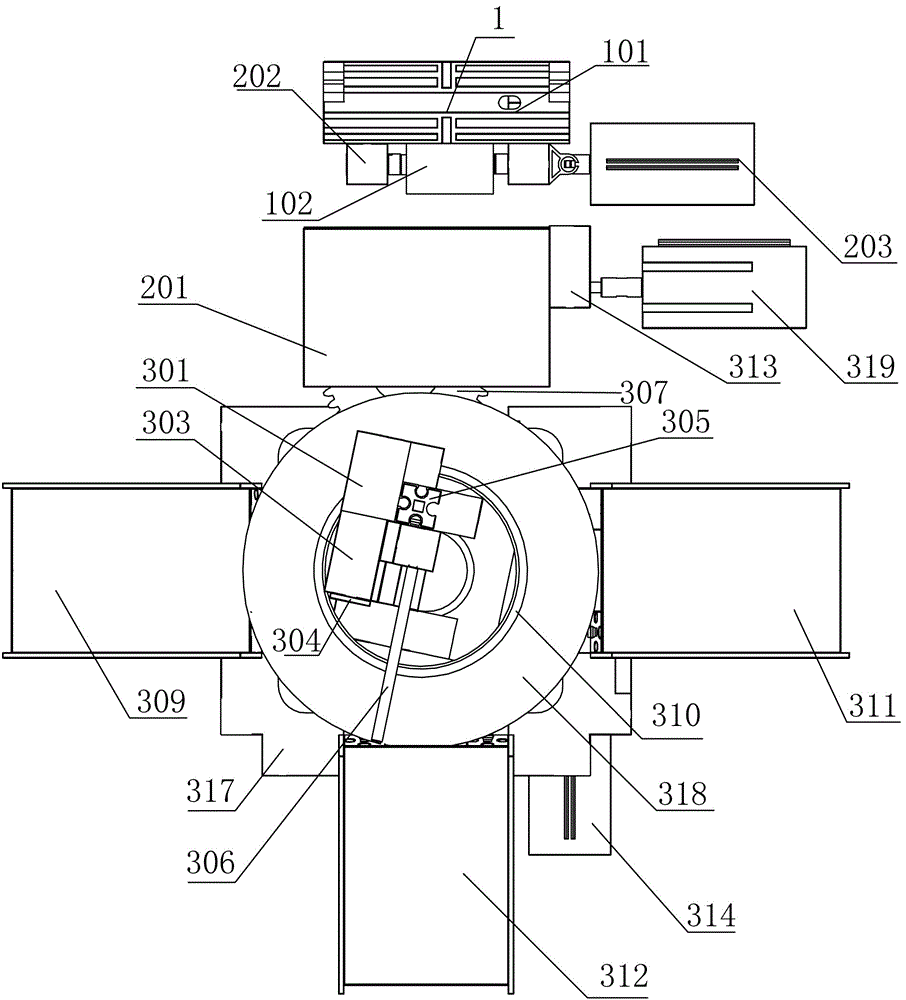

[0034] Such as Figure 1-4 , a carousel-type cargo sorting device, which includes a code scanning device 1 fixedly installed on the top of an initial transmission mechanism 2, and the initial transmission device 2 is connected to a sorting mechanism 3 through a transition plate 201.

[0035] Further, the sorting mechanism 3 includes a front bracket 313, a turntable drive motor 319 is installed on the top of the front bracket 313, and the turntable drive motor 319 meshes with the second gear 308 through a worm gear transmission, and the second gear 308 and The first gear 307 is fixedly installed on the same main shaft, and the third gear 320 at the bottom of the first gear 307 and the turntable 318 meshes to drive the turntable 318 to rotate. The bottom of the turntable 318 is provided with a rear bracket 317, and the rear bracket 317 The top is respectively provided with a plurality of chute devices along the periphery of the turntable 318, and the center of the turntable 318 ...

Embodiment 2

[0044] When there are many classification categories of goods, not limited to three types, multi-level classification devices can be connected in series. More accurate classification, thereby improving classification accuracy.

[0045] Of course, the combination of series and parallel can also be used for classification. The above-mentioned classification method will improve the classification efficiency and also increase the classification amount of goods, that is, the classification amount per unit time.

Embodiment 3

[0047] A method for automatically classifying goods by using any carousel-type cargo sorting device, which includes the following steps:

[0048] S1: Place the goods to be sorted on the conveyor belt of the initial transmission mechanism 2, and keep the side with the information barcode facing up, and drive the goods forward through the conveyor belt to reach the position of the code scanning device 1;

[0049] S2: When the goods arrive at the code scanning device 1 and pass under the code scanning device 102, the barcode is quickly identified by the code scanning device 102, and the collected information is transmitted to the main controller 4, and the main controller 4 performs the classification of the goods. classification, and send a control signal to the stepper motor 314 at the same time, the stepper motor 314 receives the control signal to drive the main support rod 305 to rotate, and the railing 306 stays at the corresponding chute position;

[0050] S3: After scannin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com