A treatment method and system for drilling and fracturing flowback fluid in oil and gas fields

A technology for fracturing flowback fluid and treatment methods, which is applied to chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., to prolong the cleaning cycle, reduce the amount of gel breaker, and improve the breaking efficiency. The effect of glue efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to better explain the present invention, the technical solutions in the embodiments of the present invention will be described clearly and completely in conjunction with the accompanying drawings in the embodiments of the present invention.

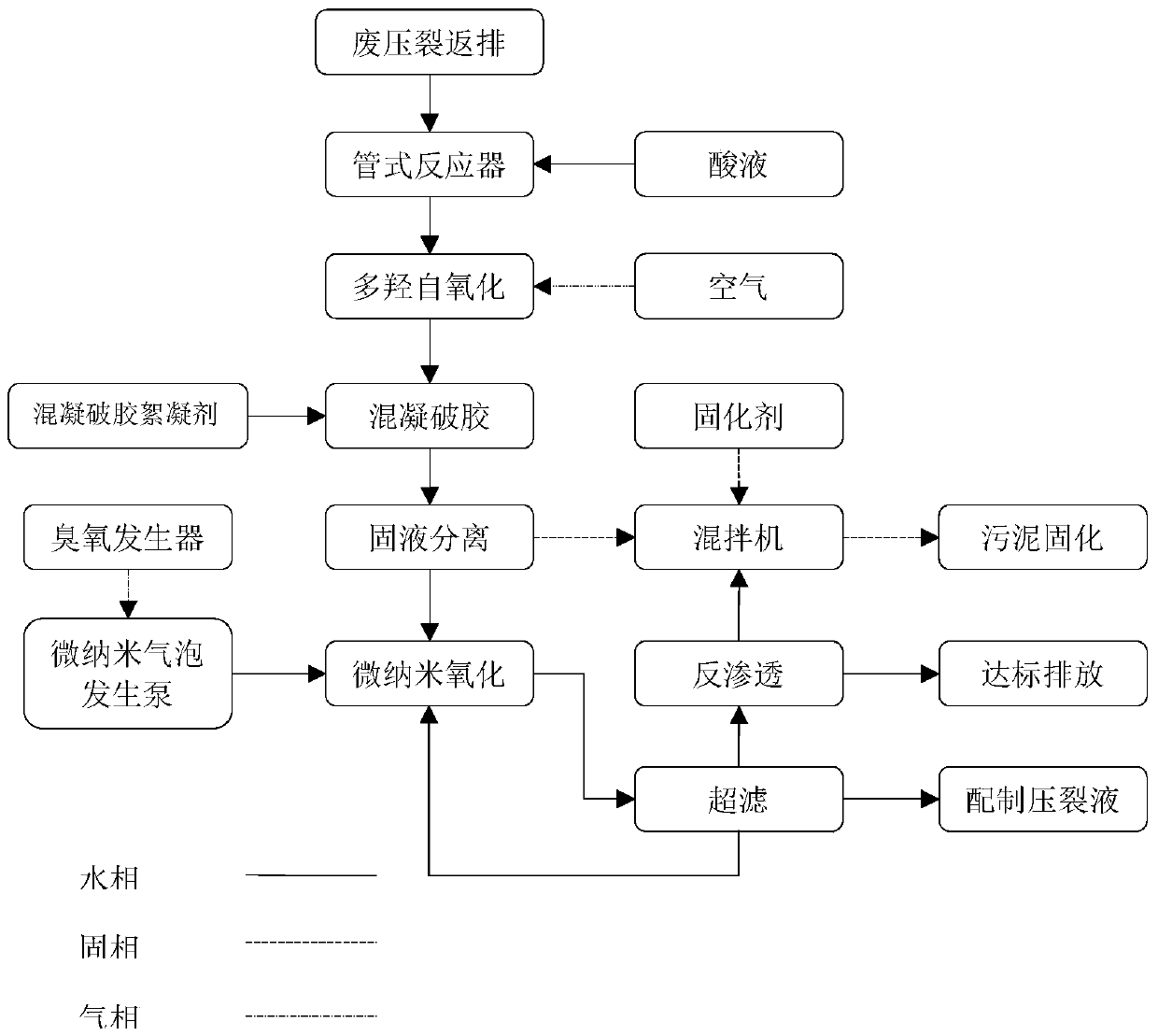

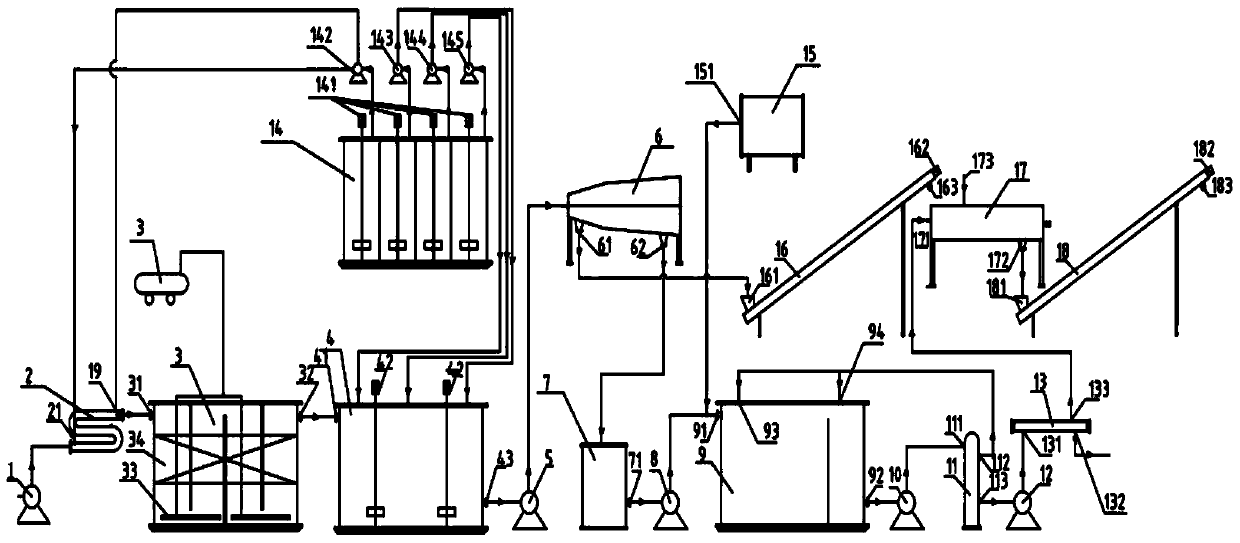

[0031] Such as figure 1 , 2 As shown, an oil and gas field drilling and fracturing flowback fluid processing method and system includes the following steps:

[0032] Step 1. Pre-acidified polyhydroxyl autooxidation: the fracturing flowback liquid is lifted by the material transfer pump 1 to the tubular reactor 2 and fully mixed with the acid liquid entering from the inlet 21. The fluid velocity in the tubular reactor 2 Gradient at 720s -1 At the end of the tubular reactor 2, an online pH meter 19 monitors the pH value of the waste fracturing flowback fluid, and feeds back the monitored signal to the acid supply pump 142 to control the flow rate. The pH-adjusted fracturing flowback fluid enters the polyhydroxy autoxidation react...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com