Full-automatic waste aluminum alloy recycling and forming machine

A waste recycling and aluminum alloy technology, applied in the direction of metal processing equipment, manufacturing tools, process efficiency improvement, etc., can solve the problems of increasing dependence on artificial labor, reducing recycling efficiency, increasing production costs, etc., so as to avoid dependence on artificial labor , improve efficiency and reduce labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing:

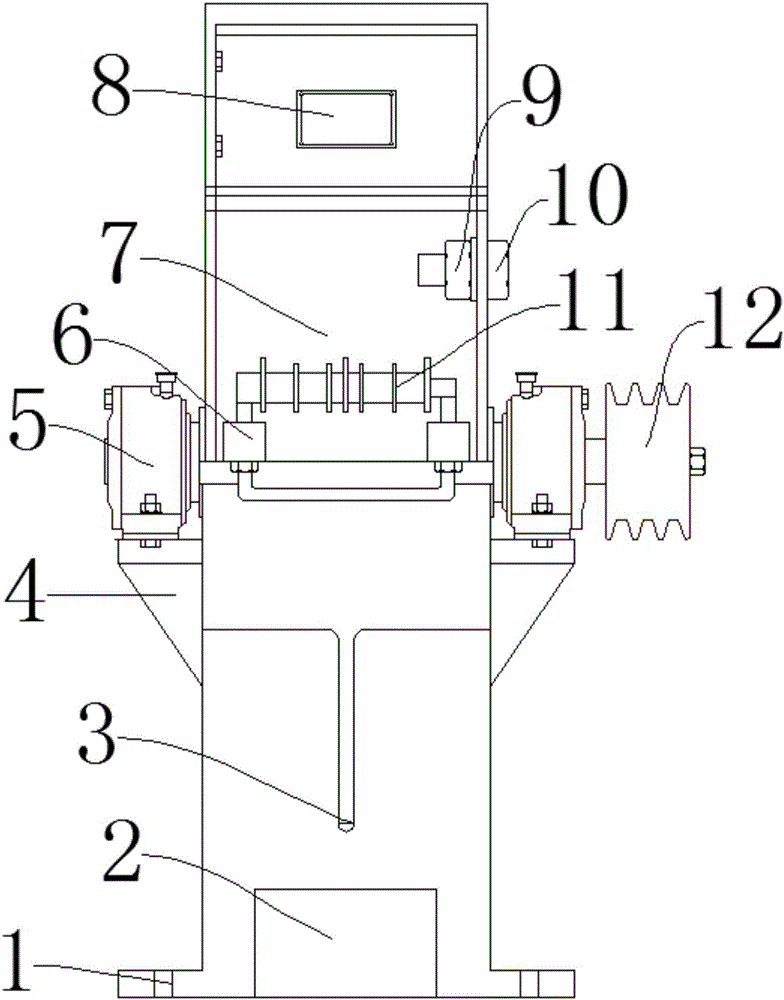

[0015] Such as figure 1 As shown, a fully automatic aluminum alloy waste recycling molding machine includes a base 1, a supporting plate 4, a waste material input pipe 8 and a temperature sensor 9, a mold holder 2 is installed on the base 1, and an injection material is arranged above the mold holder 2 An electric heater 5 is arranged above the pipe 3 and the supporting plate 4, and the electric heater 5 is connected with the pulverizer 11 through the heat conduction transmission shaft 6, and the pulverizer 11 is connected with the motor 12, and a melting chamber 7 is provided under the waste input pipe 8, and a temperature sensor 9. A temperature display 10 is arranged on the outside.

[0016] In the above structure, the mold is fixed in the mold holder 2 according to the actual needs, and the aluminum alloy waste to be recovered is sent into the melting chamber 7 through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com