A hydraulic range-extending pumping unit for an offshore platform

An offshore platform and program extension technology, which is applied to liquid variable volume machinery, mechanical equipment, machines/engines, etc., can solve the problem of not finding public documents, achieve low noise, prolong the pump inspection period, and occupy a small space. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

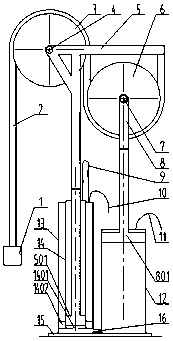

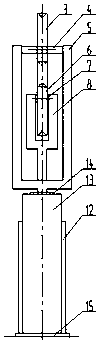

[0017] The detailed description and technical content of the present invention are described below with the accompanying drawings, but the accompanying drawings are only provided for reference and description, and are not intended to limit the present invention.

[0018] according to Figure 1-2 , a hydraulic extended-range pumping unit for offshore platforms, one end of the steel wire rope 2 is fixed on the beam of the movable support 5, bypasses the secondary sky wheel 6 and the main sky wheel 3, and is suspended on one side of the hydraulic extended-range pumping unit for the offshore platform, Connect with hanger 1.

[0019] Wherein, the main sky wheel 3 is installed on the moving bracket 5 through the main rotating shaft 4 . One side of the upper part of the moving support 5 is provided with a triangular support, and the lower end is a piston-type structure 501, which is sealed with the inner cavity of the inner liquid cylinder 14. The secondary sky wheel 6 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com