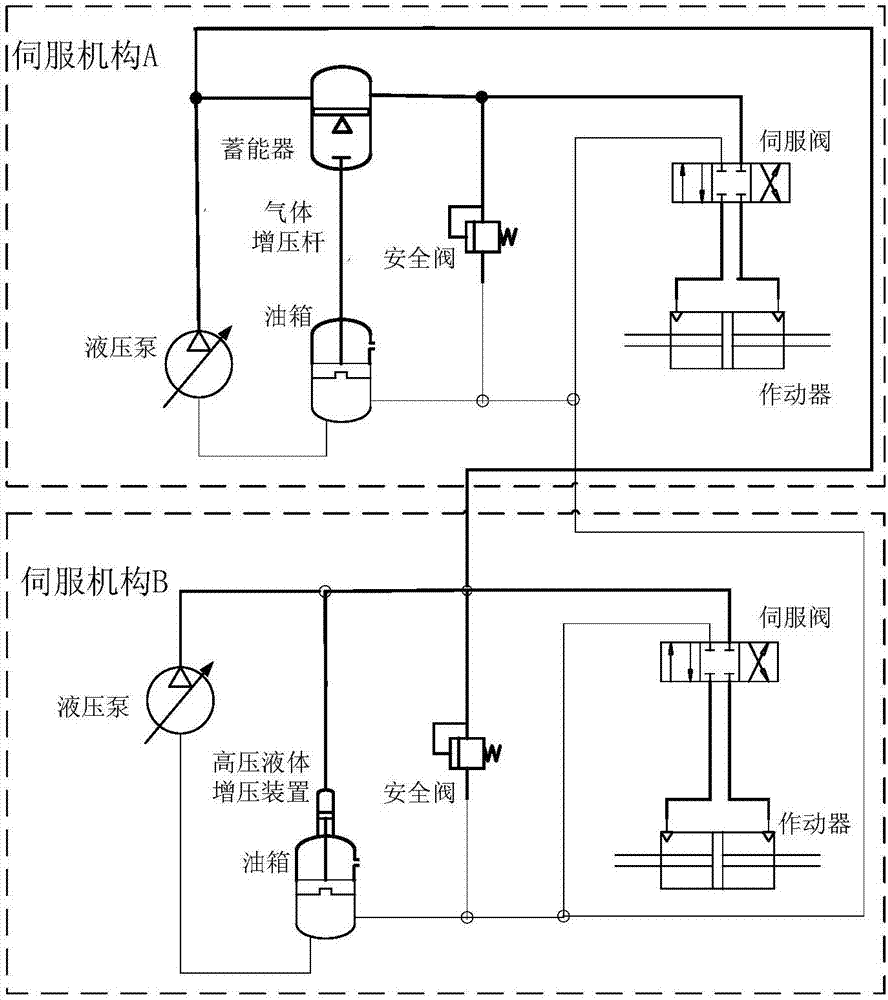

A Self-pressurizing Circuit of Servo Mechanism Working in Parallel

A servo-mechanism, self-pressurization technology, applied in mechanical equipment, accumulator devices, fluid pressure converters, etc., can solve the problems of short stroke of fuel tank piston, low spring pressure, low reliability, etc., to reduce the weight of the circuit , the effect of reducing volume and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

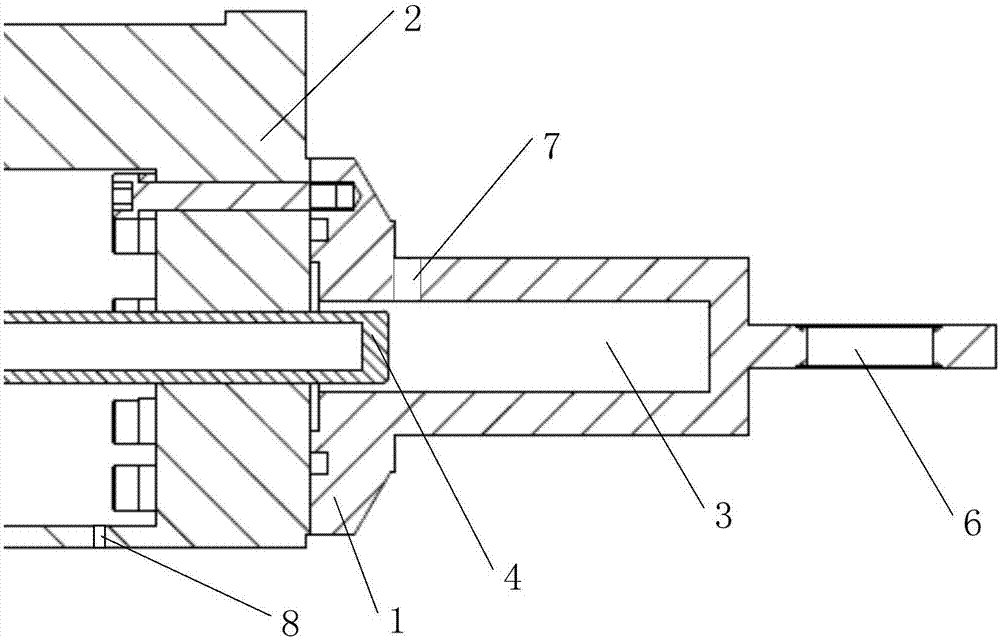

[0054] 1. Pressure of high-pressure gas booster fuel tank: accumulator pressure 6-12MPa, gas booster rod diameter 16mm, fuel tank piston diameter 80mm, ignoring the friction force of the booster rod, the pressure of the booster fuel tank can be 0.24-0.48MPa, that is, in the hydraulic pressure Before the pump starts, the circuit pressure is about 0.24~0.48MPa.

[0055] 2. Fuel tank pressure of high-pressure liquid booster: After the hydraulic pump is started, the working pressure is 20-21.5MPa, the diameter of the liquid booster rod is 14mm, and the diameter of the fuel tank piston is 80mm. Neglecting the friction force of the booster rod, the pressure of the second fuel tank is 0.61 ~0.66MPa. At this time, the gas in the accumulator is squeezed, and the gas pressure rises to be consistent with the working pressure, that is, 20-21.5MPa. The pressure of the first fuel tank is 0.8-0.86MPa, and the first fuel tank is emptied first. If the first fuel tank has not been emptied, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com