Light source module of lamp for vehicle

A technology for light source modules and vehicles, applied in the field of light source modules for lamps, can solve the problems of not being able to meet the needs of various designs of luminous images, increase manufacturing costs and weight, and increase lamp size, so as to improve marketability and reduce manufacturing costs and weight, the effect of reducing the overall size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

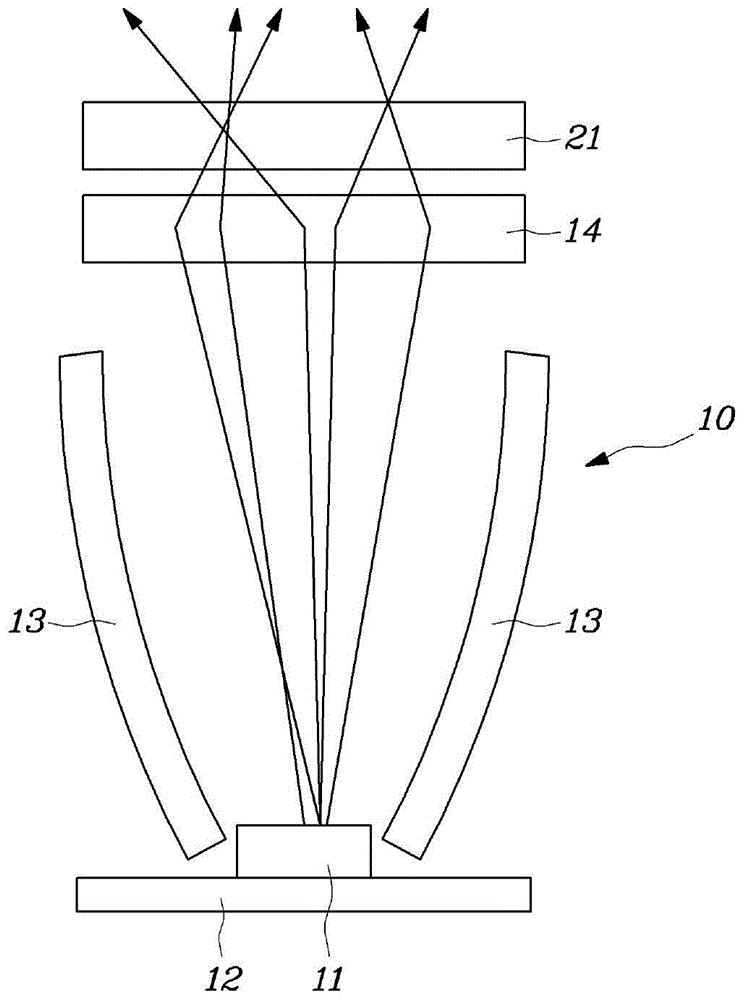

[0034] Hereinafter, a light source module for a lamp for a vehicle according to an exemplary embodiment of the present inventive concept will be described with reference to the accompanying drawings.

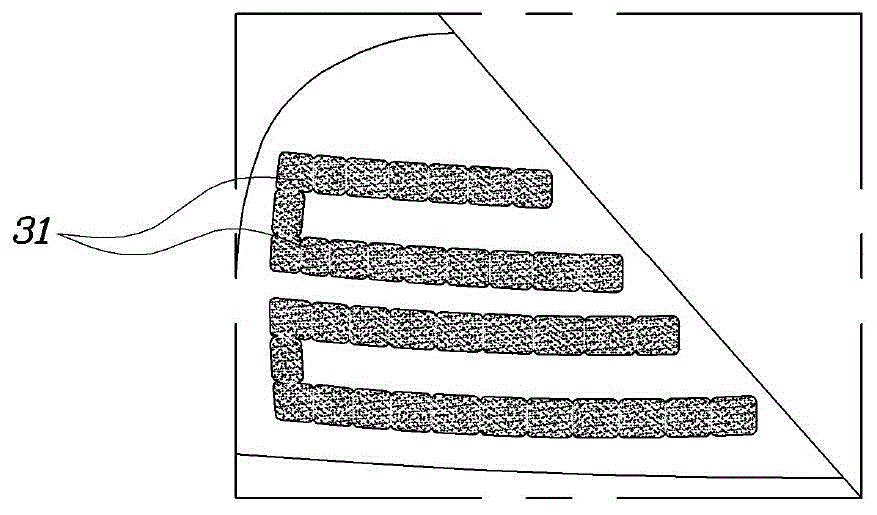

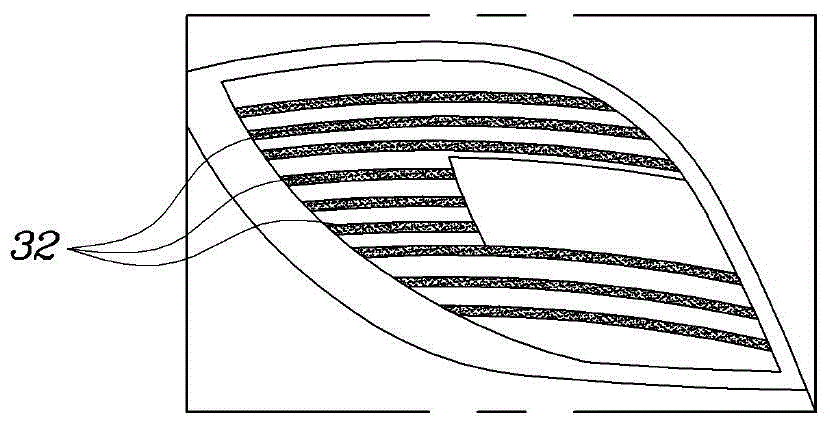

[0035] Such as Figure 3 to Figure 7 As shown, the light source module 50 for a lamp for a vehicle according to the present application includes an LED light source 51 , a PCB substrate 52 , a main pattern film 53 , an optical resin 54 and a sub pattern film 55 . The PCB substrate 52 controls the supply of current to the LED light source 51 . The main pattern film 53 is layered on the PCB substrate 52 and has a first optical protrusion 53 a formed on the main pattern film 53 . The first optical protrusion 53 a realizes the first light emitting image 61 having a specific pattern using the light of the LED light source 51 . The optical resin 54 is layered on the main pattern film 53 and uniformly transmits light from the LED light source 51 throughout the entire cross section of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com