Light barrier for movable light barrier switching device

A technology for switching devices and light shields, which is applied to lighting devices, fixed lighting devices, components of lighting devices, etc., can solve the problems of production noise, reduce the lifespan of light shielding plates, and block, and achieve the effect of improving lifespan and convenient and quick installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

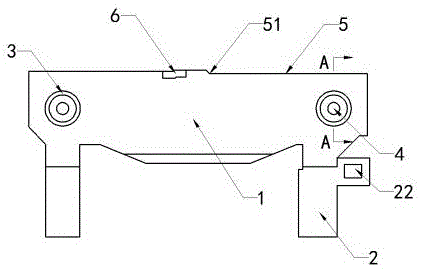

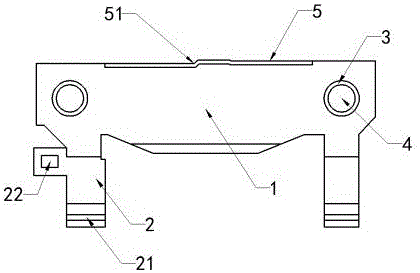

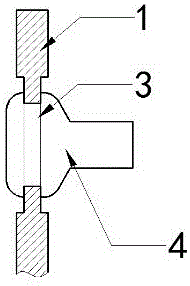

[0014] Depend on figure 1 , figure 2 , image 3 It is known that a light baffle for a movable light baffle switching device includes a light baffle main body 1. The light baffle main body 1 is an integrally formed cast aluminum part, which can quickly dissipate heat. The mounting foot 2 connected to the electromagnetic valve component is provided with a card slot 21 on the mounting foot 2, and a fixing hole 22 for connecting a return spring is also provided on the mounting foot 2 at one end. The connection between the card slot 21 on the mounting foot 2 and the movable shaft on the solenoid valve component is completed by interference fit, which is convenient and quick to install. One end of the return spring fixedly installed on the solenoid valve component is fixedly connected to the fixing hole 22 on the mounting foot 2. Inside, the two ends of the main body of the light barrier 1 are provided with a counterbore 3, and a rubber pad 4 is fixedly installed in the counterbo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com