Method for manufacturing high-effect low-cost LED lamp heat radiation protection mechanism

A technology of LED lamp and protection mechanism, which is applied to lighting and heating equipment, cooling/heating device of lighting device, lighting device, etc., can solve the problems of discount of advantages of LED lights, waste of manufacturing materials, high cost, and flexible appearance design. The effect of enrichment, saving of manufacturing materials, and reduction of manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028]The manufacturing method of the high-efficiency and low-cost LED lamp heat dissipation protection mechanism of the present invention is:

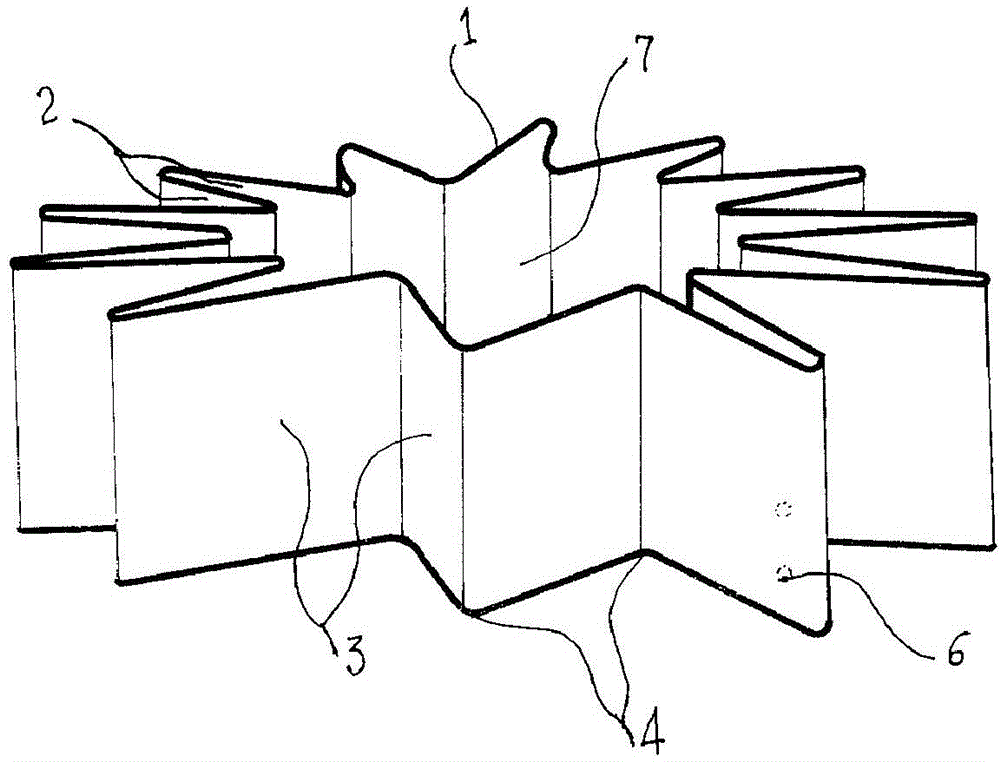

[0029] a. Bending the sheet-like or plate-like heat transfer material layer 1 at positive and negative intervals to have several corners 4, heat transfer walls 3 or / and flat walls 5, and heat dissipation intervals 2;

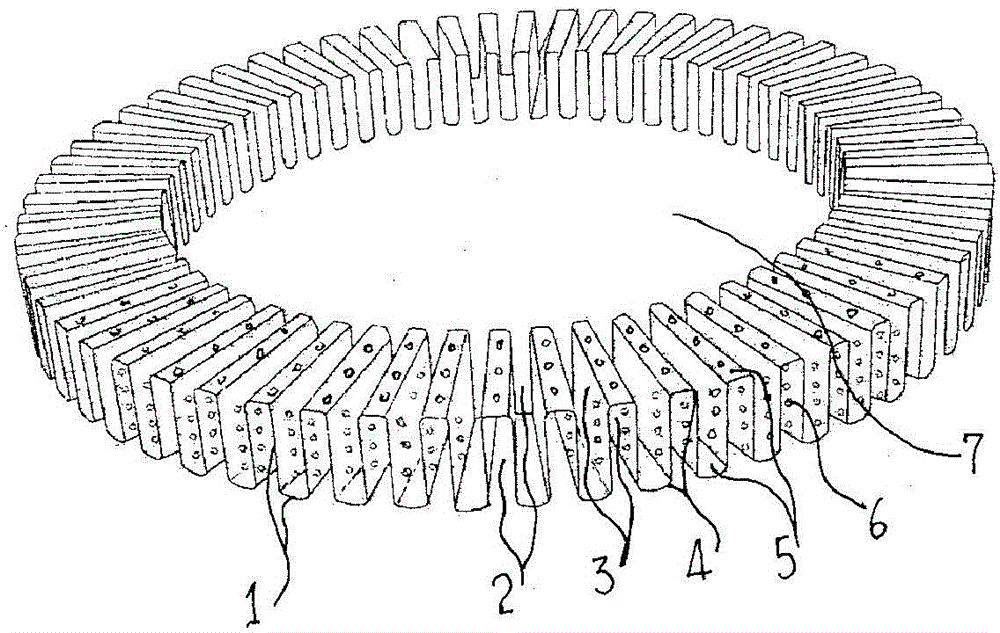

[0030] b. Connect the two ends of the heat transfer material layer 1 with several bends 4, heat transfer walls 3 or / and flat walls 5, and heat dissipation intervals 2 that are folded at intervals between the front and back sides, or be coiled and fixed from one end to the other end, A heat dissipation body with curved corners 4, heat transfer walls 3 or / and flat walls 5, and heat dissipation intervals 2 is formed.

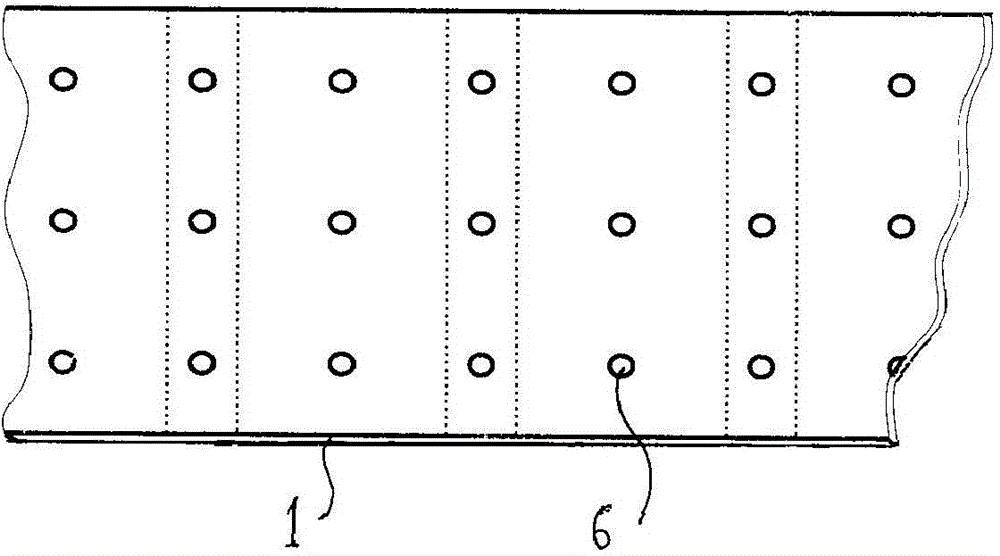

[0031] The high-efficiency and low-cost LED lamp heat dissipation protection mechanism manufactured by the present invention has a heat transfer material layer 1, the heat transfer material layer 1 is folded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com