Industrial robot for X-ray detection

An industrial robot and robot technology, applied in manipulators, manufacturing tools, program-controlled manipulators, etc., can solve the problems of multiple raw materials, heavy industrial robots, complex control systems, etc., and achieve the effect of reducing weight and saving manufacturing materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

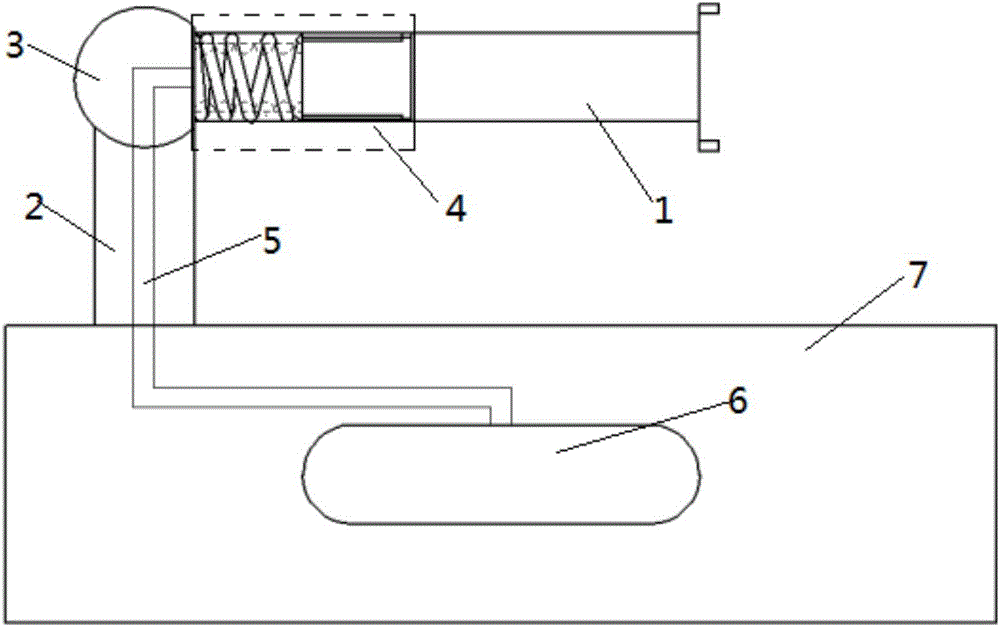

[0027] see Figure 1~2 , the application provides an industrial robot for X-ray detection, including an arm component, the arm component includes a first mechanical arm 1, a second mechanical arm 2 and a joint 3, and the end of the first mechanical arm 1 is provided with There is an auxiliary inflatable component 4 , which is connected to the second mechanical arm 2 through a joint 3 ; the auxiliary inflatable component 4 is connected to an air pump 6 through an air pipe 5 .

[0028] The specific working process of this application is as follows: when using the industrial robot involved in this application, when the first mechanical arm 1 needs to be extended, the auxiliary inflatable member 4 is inflated by the air pump 6 through the air delivery pipe 5, and the auxiliary inflatable member 4 is directed to The front movement drives the first mechanical arm 1 connected to it to move, and the extension of the first mechanical arm 1 can be realized; similarly, the air pump 6 is ...

Embodiment 2

[0031] see Figure 1~2 , the application provides an industrial robot for X-ray detection, including an arm component, the arm component includes a first mechanical arm 1, a second mechanical arm 2 and a joint 3, and the end of the first mechanical arm 1 is provided with There is an auxiliary inflatable component 4 , which is connected to the second mechanical arm 2 through a joint 3 ; the auxiliary inflatable component 4 is connected to an air pump 6 through an air pipe 5 .

[0032] Optionally, a base 7 is also included, and the air pump 6 is arranged in the base 7 .

[0033] The specific working process of the present application is as follows: when using the industrial robot involved in the present application, when the first mechanical arm 1 needs to be extended, the auxiliary inflatable member 4 is carried out by the air pump 6 arranged in the base 7 through the air delivery pipe 5. Inflated, the auxiliary inflatable member 4 moves forward to drive the first mechanical a...

Embodiment 3

[0036] see Figure 1~2 , the application provides an industrial robot for X-ray detection, including an arm component, the arm component includes a first mechanical arm 1, a second mechanical arm 2 and a joint 3, and the end of the first mechanical arm 1 is provided with There is an auxiliary inflatable component 4 , which is connected to the second mechanical arm 2 through a joint 3 ; the auxiliary inflatable component 4 is connected to an air pump 6 through an air pipe 5 .

[0037] Optionally, a base 7 is also included, and the air pump 6 is arranged in the base 7 .

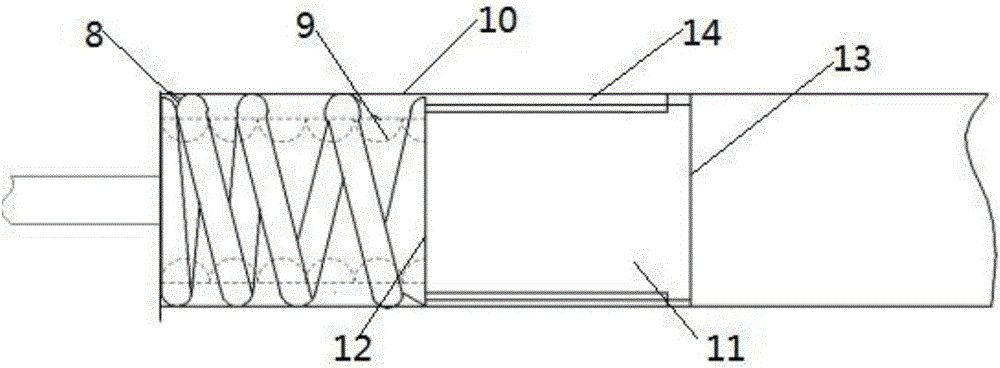

[0038] Optionally, the auxiliary inflatable member 4 includes a spring 8, an air bag 9 and a telescoping assembly.

[0039]The specific working process of the present application is as follows: when using the industrial robot involved in the present application, when the first mechanical arm 1 needs to be extended, the air pump 6 arranged in the base 7 is used to charge the auxiliary inflatable member 4 throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com