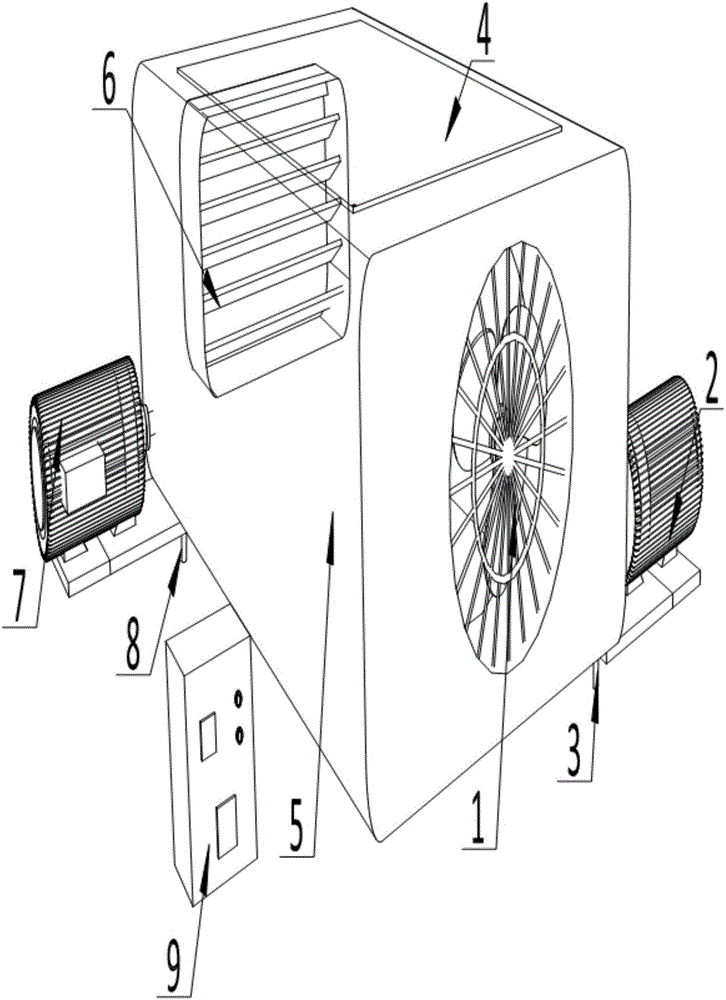

Large commercial air exchanger and automatic control system thereof

An air switch and commercial technology, applied in the field of air purification, can solve the problems of failing to meet national standards, slow purification speed, unable to introduce fresh air, etc., and achieve the effect of good air purification effect, high degree of intelligence, and improvement of indoor air quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

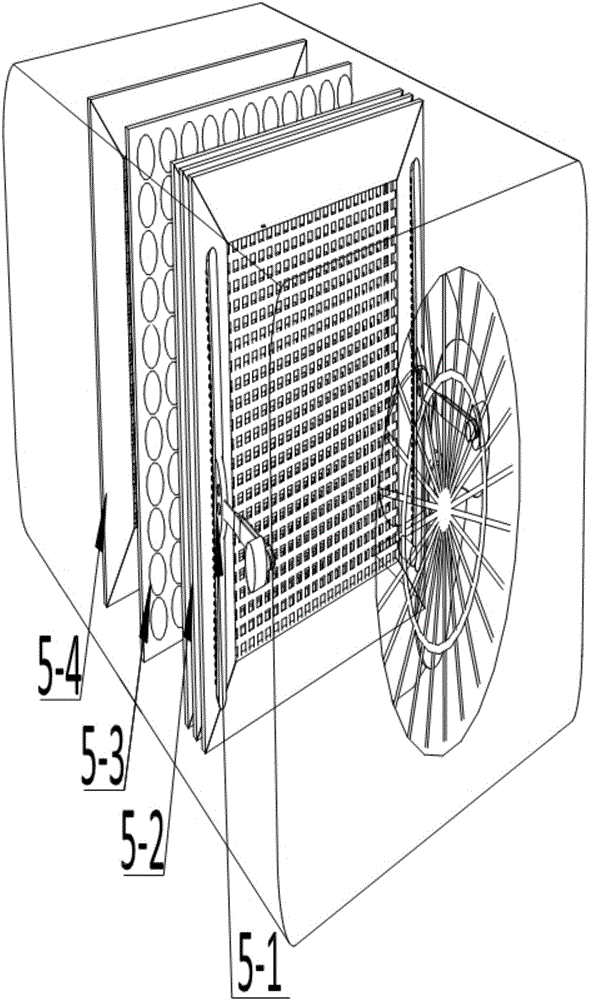

[0055] The high-efficiency sterilizing filter screen 5-2-3 of the present invention is manufactured according to the following steps, and is calculated in parts by weight:

[0056] Step 1: Add 998 parts of ultrapure water with a conductivity of 1.28 μS / cm into the reaction kettle, start the stirrer in the reaction kettle, the speed is 45 rpm, start the heating pump, and make the temperature in the reaction kettle rise to 52 ℃; 42 parts of 4-isopropyl-2-propenyltoluene, 2,2-dimethyl-3-(2-methyl-1-propenyl)cyclopropanecarboxylic acid-3,4,5,6-tetrahydro 18 parts of peptide imidomethyl ester, 86 parts of 4-4-[bis(2-chloroethyl)amino-2-methoxybenzylidene]-2-phenyloxazolin-5-one, Stir until completely dissolved, adjust the pH value to 2.5, adjust the stirring speed to 114 rpm, the temperature is 76 ° C, and the esterification reaction is performed for 14 hours;

[0057] Step 2: Take (R,S)-α-cyano-3-phenoxybenzyl(1R,3R)-3-(2,2-dichlorovinyl)-2,2-dimethyl ring 38 parts of propanecar...

Embodiment 2

[0062] The high-efficiency sterilizing filter screen 5-2-3 of the present invention is manufactured according to the following steps, and is calculated in parts by weight:

[0063] Step 1: Add 1125 parts of ultrapure water with a conductivity of 2.12 μS / cm into the reaction kettle, start the agitator in the reaction kettle, turn the speed at 70 rpm, start the heating pump, and make the temperature in the reaction kettle rise to 68 ℃; 78 parts of 4-isopropyl-2-propenyltoluene, 2,2-dimethyl-3-(2-methyl-1-propenyl)cyclopropanecarboxylic acid-3,4,5,6-tetrahydro 36 parts of peptide imidomethyl ester, 124 parts of 4-4-[bis(2-chloroethyl)amino-2-methoxybenzylidene]-2-phenyloxazolin-5-one, Stir until completely dissolved, adjust the pH value to 5.6, adjust the stirring speed to 185 rpm, the temperature is 114 ° C, and the esterification reaction is carried out for 21 hours;

[0064] Step 2: Take (R,S)-α-cyano-3-phenoxybenzyl(1R,3R)-3-(2,2-dichlorovinyl)-2,2-dimethyl ring 78 parts of...

Embodiment 3

[0069] The high-efficiency sterilizing filter screen 5-2-3 of the present invention is manufactured according to the following steps, and is calculated in parts by weight:

[0070] Step 1: Add 1,354 parts of ultrapure water with a conductivity of 3.22 μS / cm into the reaction kettle, start the agitator in the reaction kettle, the speed is 96 rpm, start the heating pump, and make the temperature in the reaction kettle rise to 86 ℃; 114 parts of 4-isopropyl-2-propenyltoluene, 2,2-dimethyl-3-(2-methyl-1-propenyl)cyclopropanecarboxylic acid-3,4,5,6-tetrahydro 52 parts of peptide imidomethyl ester, 154 parts of 4-4-[bis(2-chloroethyl)amino-2-methoxybenzylidene]-2-phenyloxazolin-5-one, Stir until completely dissolved, adjust the pH value to 7.2, adjust the stirring speed to 254 rpm, the temperature is 156 ° C, and the esterification reaction is carried out for 32 hours;

[0071] Step 2: Take (R,S)-α-cyano-3-phenoxybenzyl(1R,3R)-3-(2,2-dichlorovinyl)-2,2-dimethyl ring 104 parts of p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Telescopic | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com