Dehumidification type temperature increasing heat source

A heat source and wet technology, applied in heating devices, lighting and heating equipment, drying, etc., can solve the problems of low energy utilization rate of equipment, backward drying process, high drying cost, etc., achieve high energy utilization efficiency, improve drying Effect of dry heating temperature and energy consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

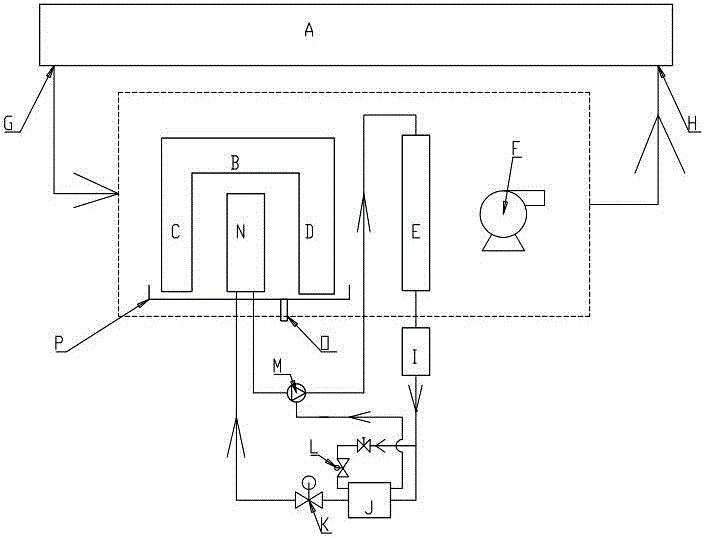

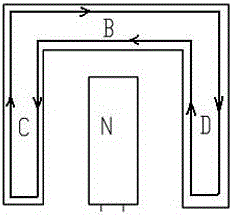

[0021] Such as figure 1 As shown, a dehumidification-type heating heat source includes an overflow air duct driven by a circulating fan F, and the overflow air duct is sequentially provided with a precooler C, an evaporator N, a reheater D, and a A stage condenser E, and a gas pipe and a liquid pipe connecting pipe B independent of each other are arranged between the precooler C and the reheater D, such as figure 2 As shown, part of the gasification substance in the precooler C enters the reheater D through the gas pipe and the gas pipe in the liquid pipe connecting pipe B, and the gas entering the heat pipe of the reheater D is liquefied and then passes through the gas pipe and the liquid pipe connecting pipe B The liquid pipe in the evaporator flows back to the precooler C, the gas outlet of the evaporator N is connected to the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com