Isolating type triaxial test device

A triaxial test, isolated technology, applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problems of large volume of the test device, cumbersome and time-consuming operation, oil filling and draining, etc. The effect of work efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing and embodiment describe in detail:

[0031] 1. Overall

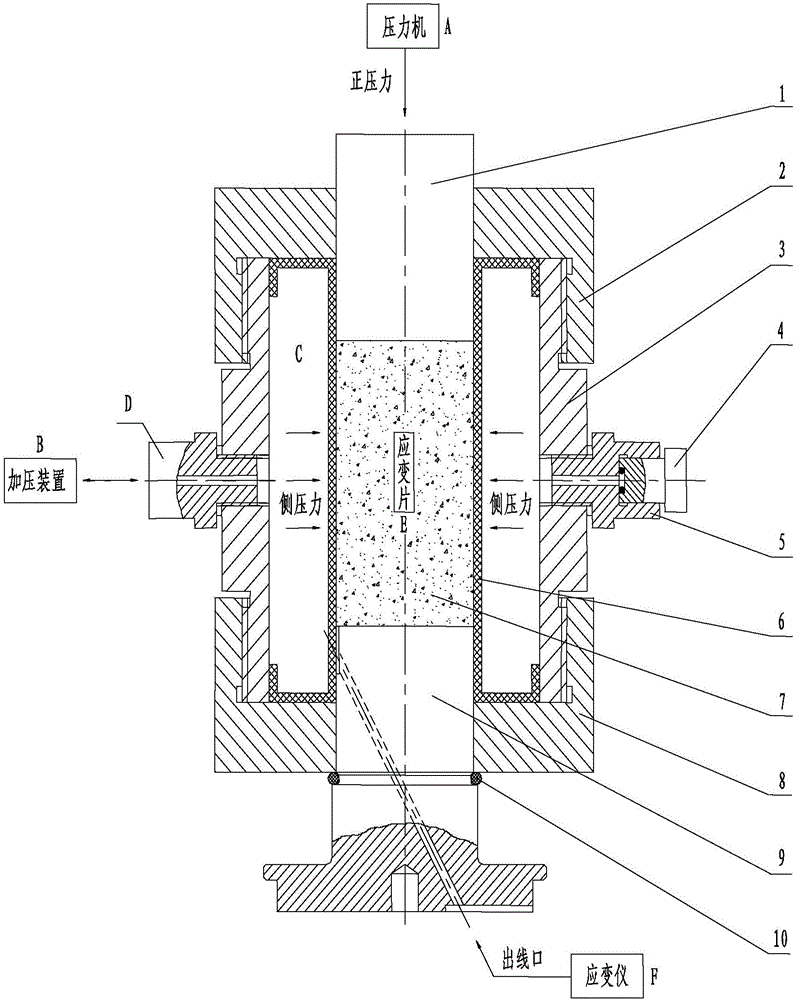

[0032] Such as figure 1 , the device includes a press A, a pressurizing device B, hydraulic oil C, a pipe joint D, a strain gauge E and a strain gauge F;

[0033] It is equipped with an upper pressure head 1, an upper transparent cover 2, a pressure chamber 3, a plug 4, a plug seat 5, an isolation sleeve 6, a sample 7, a lower transparent cover 8, a lower pressure head 9 and an elastic pad 10;

[0034] Its location and connection relationship are:

[0035] The upper and lower parts of the pressure chamber 3 are respectively connected with upper and lower transparent covers 2 and 8 to form an overall space, and along the center line of the overall space from bottom to top, the lower indenter 9, the sample 7 and the upper indenter 1 are arranged in sequence. , the lower pressure head 9 is covered with an elastic pad 10, and is isolated from the inner wall of the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com